Link-type multi-leg robot

A multi-legged robot and connecting rod technology, applied in the field of robotics, can solve the problems of restricting the movement space of the feet, achieve good dynamic response ability, reduce the overall weight, and facilitate the assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

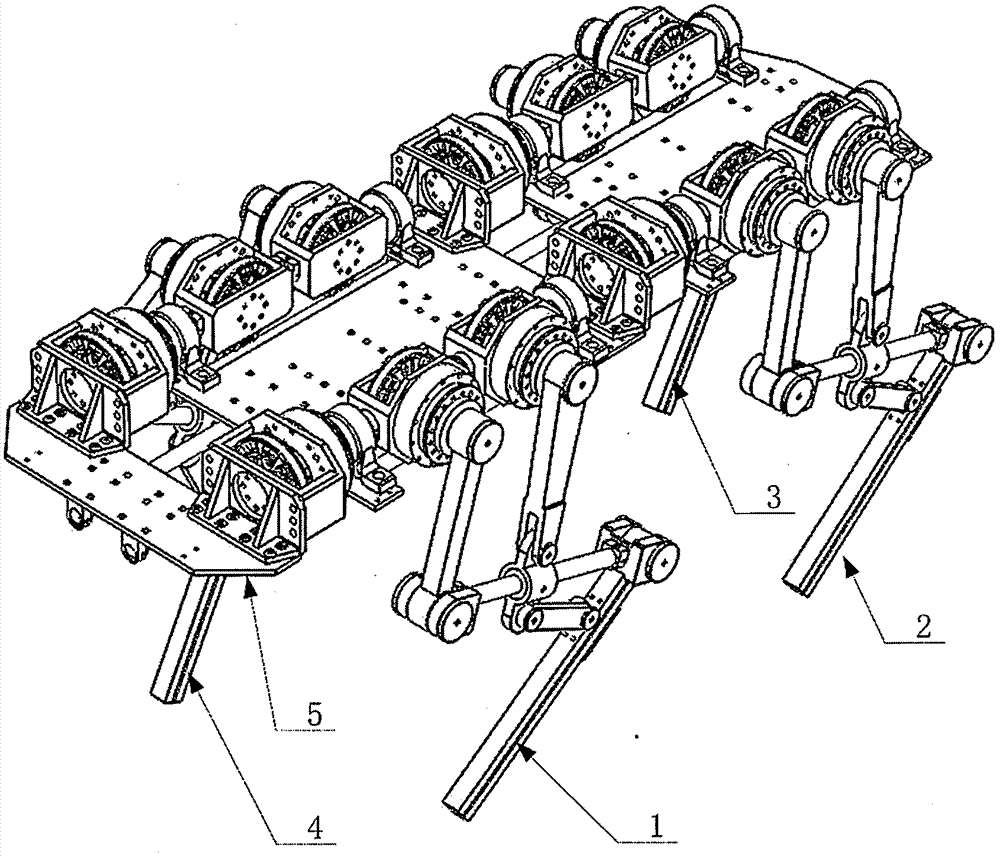

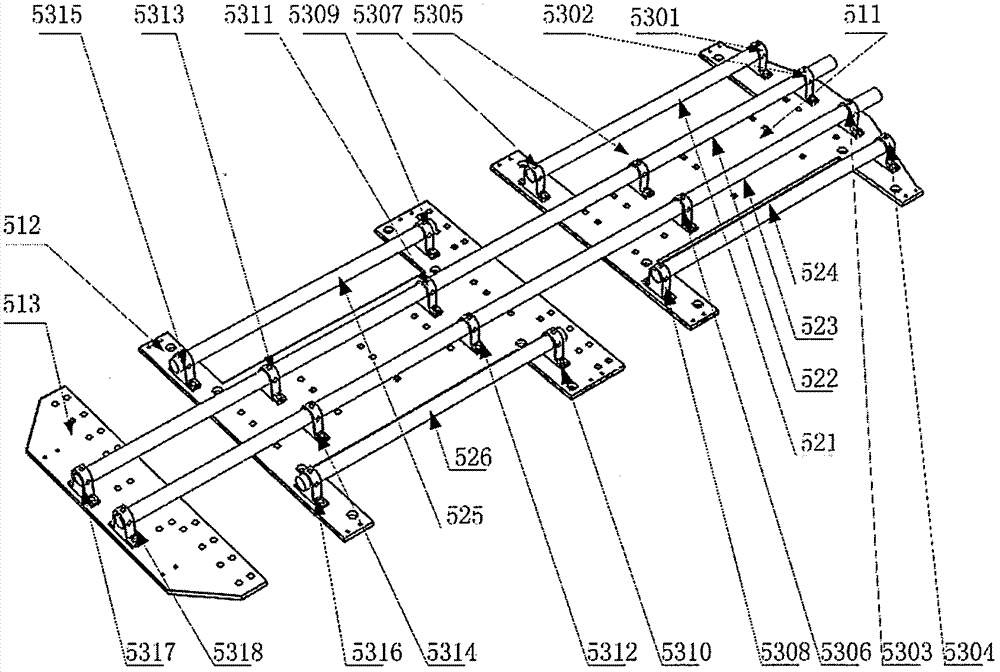

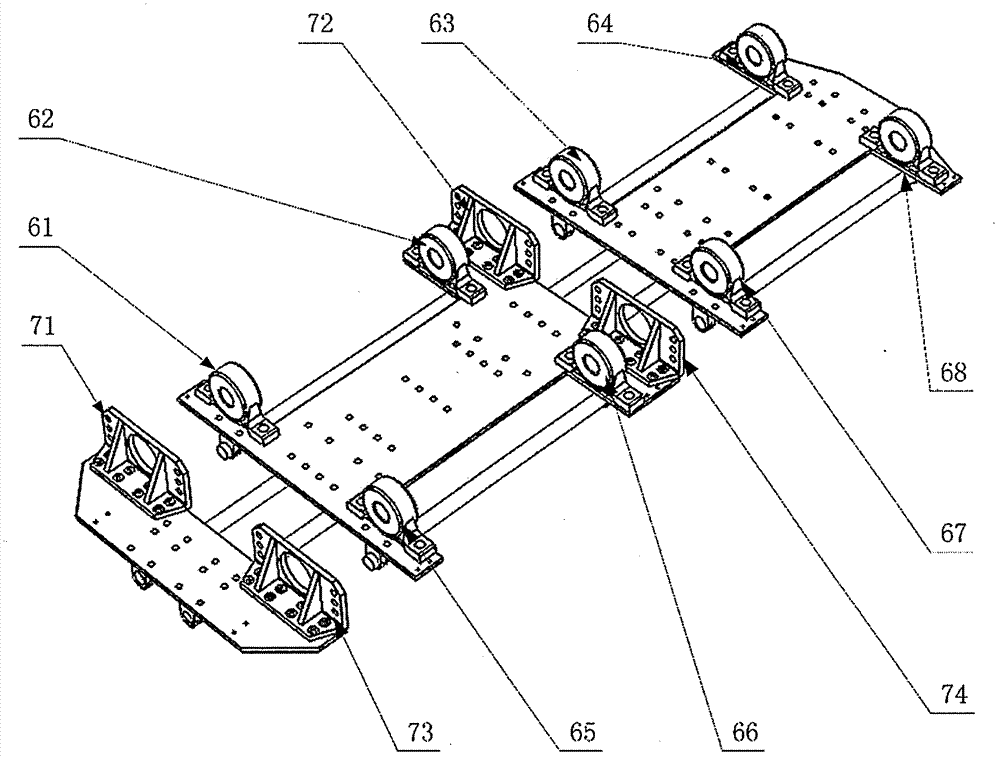

[0026] Such as figure 1 , figure 2 As shown, the robot comprises a left front foot unit 1, a left rear foot unit 2, a right front foot unit 3, a right rear foot unit 4, and a frame unit 5, wherein the frame unit 5 includes first to third base plates (511, 512 . 5309, 5310, 5311, 5312, 5313, 5314, 5315, 5316, 5317, 5318).

[0027] Such as figure 2 As shown, the bottom plate 511 is a carbon fiber plate molded part, and the connecting parts 5301, 5304, 5307, and 5308 are installed on the lower surface of the bottom plate 511 and symmetrically distributed outside its center line. The two ends of the connecting rod 521 The two ends of the connecting rod 524 are fixedly connected with the connecting piece 5307 and the connecting piece 5308 respectively. The connecting piece 5302, the connecting piece 5303, the connecting piece 5305 and the connecting piece 5306 are installed on the The lower surface is symmetrically distributed inwardly of its centerline.

[0028] The bottom ...

Embodiment 2

[0039] Such as Figure 8 As shown in the figure a in the middle, only the limit screw of the bearing end cover needs to be loosened, and the connecting rod of the thigh joint and the connecting rod of the lower leg are separated from the output shaft of the reducer of the thigh joint and the output shaft of the reducer of the lower leg respectively, so that the right forefoot unit can be realized. Rapid separation of drive structure and transmission structure.

[0040] Such as Figure 8 As shown in figure b in the middle, the transmission structure of the right forefoot unit 3 is turned over along the horizontal plane during assembly, so that the deformation from the elbow joint to the knee joint can be realized.

[0041] Such as Figure 8 As shown in figure c in the middle, connect the thigh joint connecting rod and the lower leg joint connecting rod with the output shaft of the lower leg joint reducer and the output shaft of the lower leg joint reducer respectively, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com