A Novel Electrolyzer Sludge Discharging System and Its Method

An electrolytic cell and mud system technology, applied in the field of metallurgy, can solve problems such as high cost and low efficiency, and achieve the effects of preventing pipeline blockage, saving time, and increasing flushing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

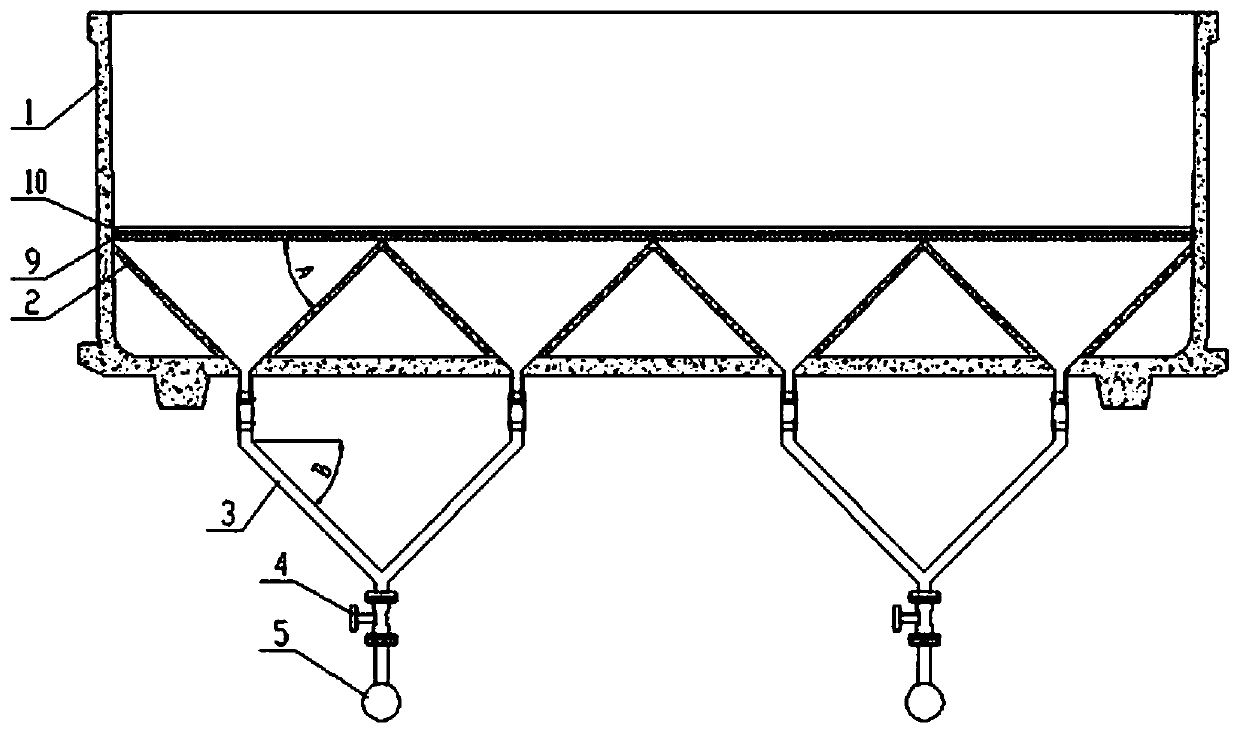

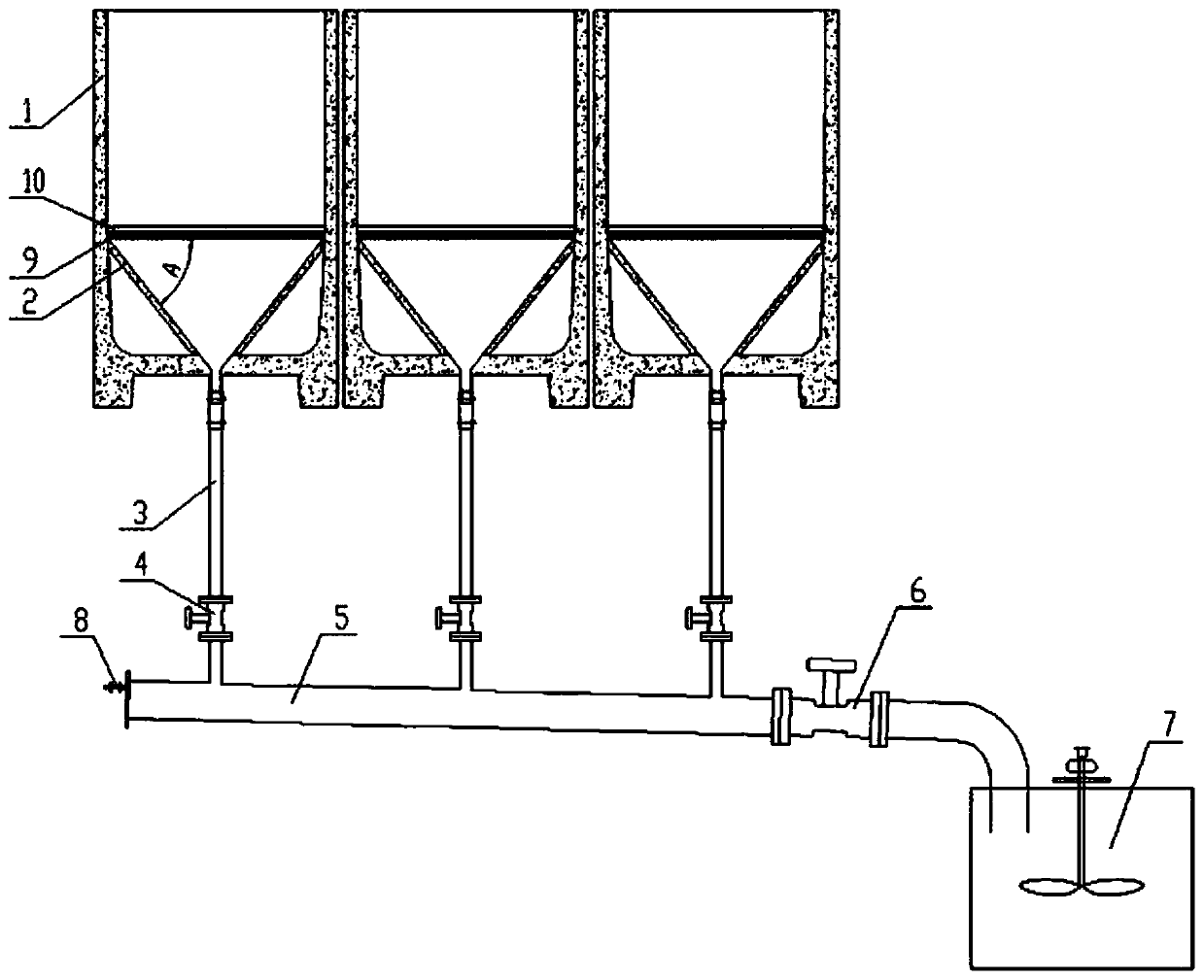

[0041] combine figure 2 as well as image 3As shown, a new copper electrolytic cell mud discharge system includes a copper electrolytic cell body 1, a settling cone 2 arranged at the bottom of the cell 1, and a lower sludge discharge branch pipe connected to the lower end of the settling cone 2 3. The lower mud discharge main pipe 5 of the electrolytic cell, the flushing fluid valve 8 and the anode slime collection tank 7 arranged at the lower end of the mud discharge branch pipe 3; Valve 4, one of the mud discharge branch pipe valve 4 controls two mud discharge branch pipes 3 at the same time, one end of the mud discharge main pipe 5 is installed with a flushing liquid valve 8, and the other end of the mud discharge main pipe 5 away from the flushing liquid valve 8 is installed in sequence There are mud discharge main pipe valve 6 and anode mud collection tank 7, each mud discharge main pipe 5 is connected with three mud discharge branch pipe valves 4 at the same time, and ...

Embodiment 2

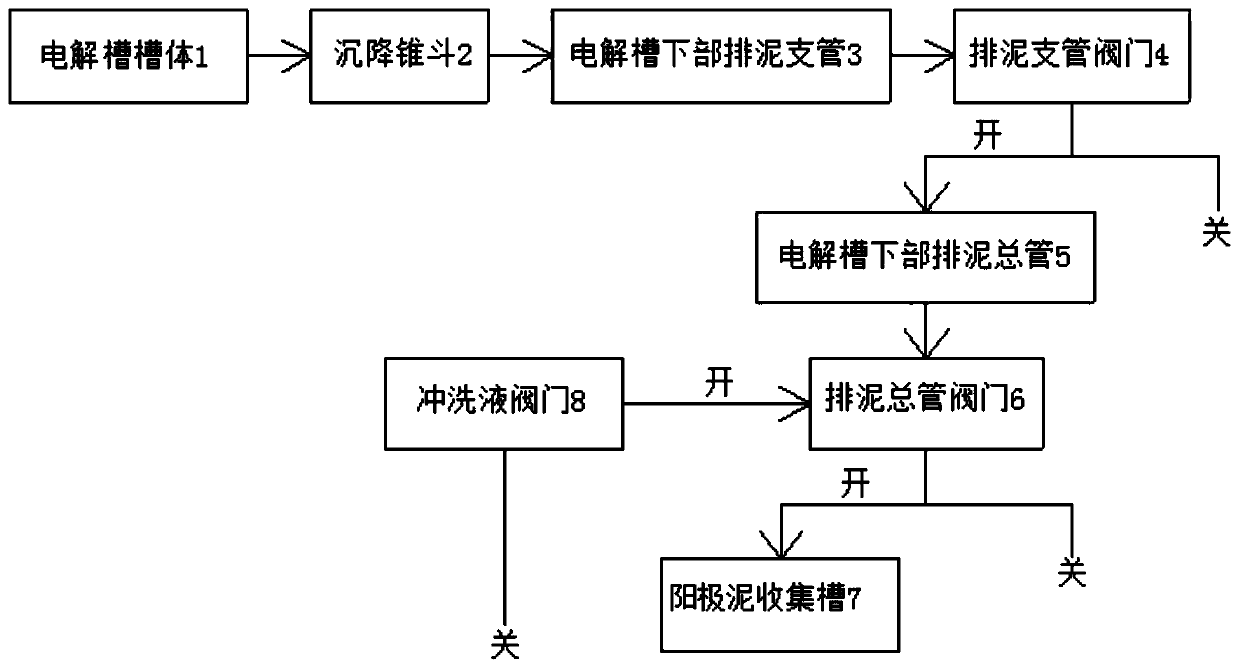

[0044] like figure 1 As shown, the intermittent sludge discharge method includes the following steps:

[0045] (1) Before the operation of the electrolysis system, close the valve 6 of the sludge discharge main pipe and the valve 8 of the flushing liquid, and open the valve 4 of the sludge discharge branch pipe;

[0046] (2) When the electrolysis system is running, the anode slime generated in real time in the upper part of the electrolytic cell 1 continuously falls to the settling cone 2 under the action of gravity, and then slides along the side of the settling cone 2 to the sludge discharge branch 3 under the tank and continue to slide along the branch pipe 3, and finally the anode mud enters the mud discharge main pipe 5 after passing through the mud discharge branch pipe valve 4;

[0047] (3) After the electrolysis system has been running for a period of time, close the sludge discharge branch pipe valve 4, open the sludge discharge main pipe valve 6 and the flushing liq...

Embodiment 3

[0050] like figure 1 Shown, continuous sludge discharge method, comprises the steps:

[0051] (1) Before the operation of the electrolysis system, open the mud discharge branch valve 4 and the mud discharge main pipe valve 6, and close the flushing liquid valve 8;

[0052] (2) When the electrolysis system is in operation, the anode slime generated in real time in the upper part of the electrolytic cell body 1 falls down to the settling cone bucket 2, the sludge discharge branch pipe 3, the sludge discharge branch pipe valve 4, the sludge discharge main pipe 5 and the discharge pipe in turn under the action of gravity. The mud main pipe valve 6 finally enters the anode slime collection tank 8 to complete the collection of anode slime; by adjusting the opening degree of the branch pipe valve 4 and the mud discharge main pipe valve 6, it is ensured that most of the anode slime and a small amount of solution enter the anode slime collection In the tank 7, but does not affect the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com