A telescopic bracket system for building construction

A technology of telescopic support and building construction, which is applied to the preparation of building components on site, construction, building construction, etc. It can solve the problems of low reuse rate of construction equipment, difficulty in ensuring section size, and difficulty in installing and dismantling support equipment. It achieves the effects of convenient and quick assembly and disassembly, adjustable section size and good support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

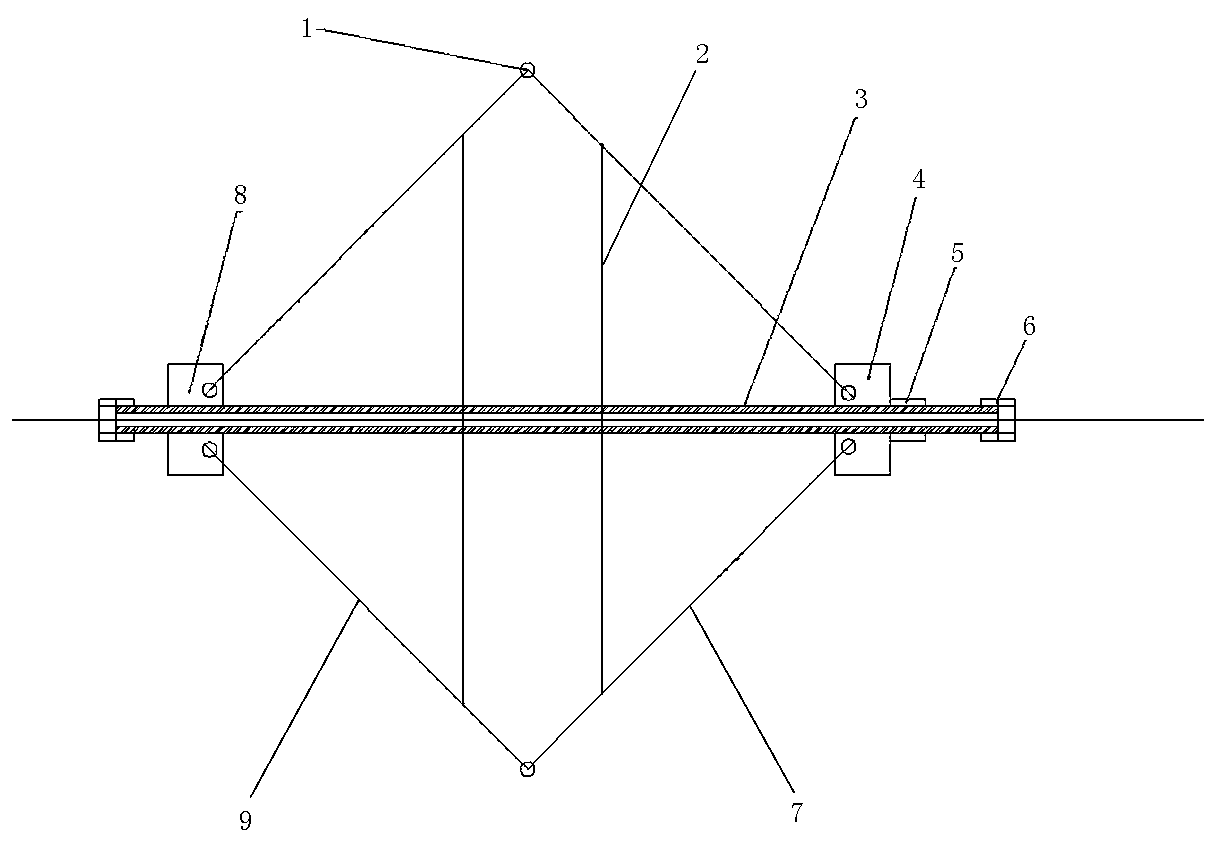

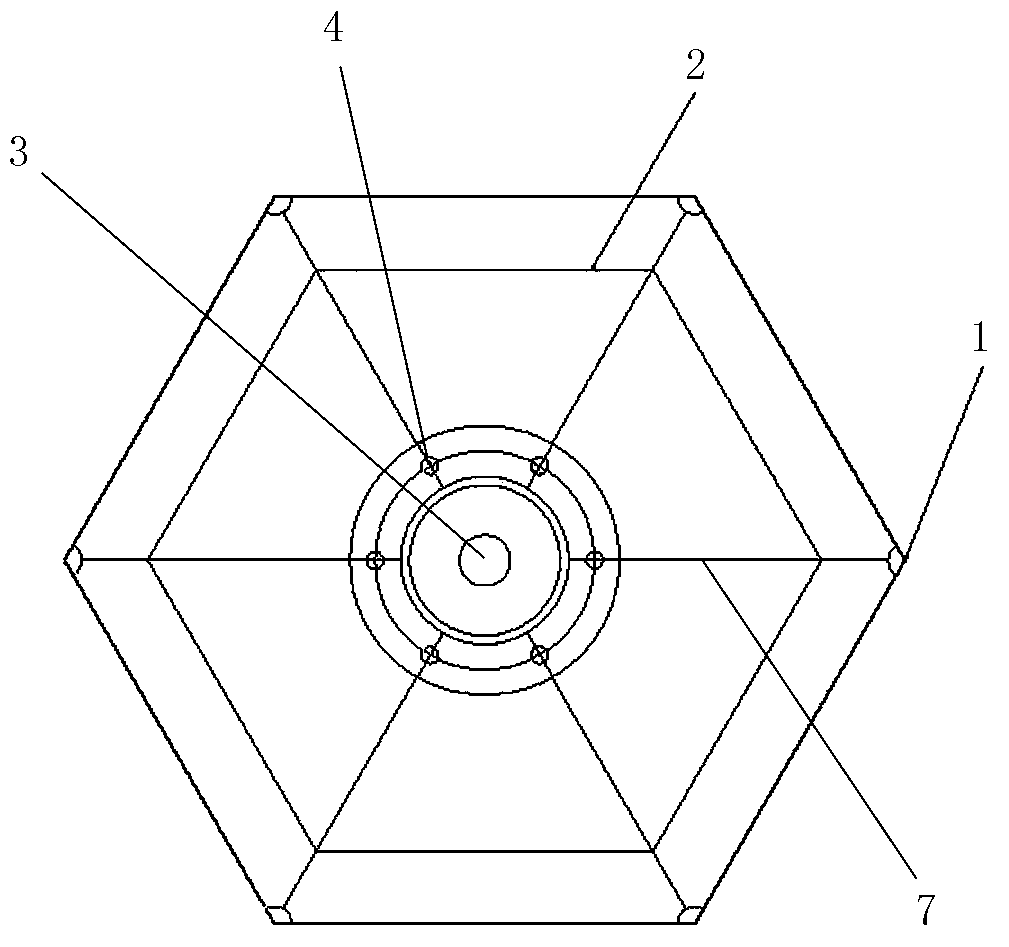

[0014] Example 1: Such as Figure 1 to Figure 3 As shown, a telescopic support system for building construction includes a screw 3, a first pole 7 and a second pole 9. Both ends of the screw are provided with screw connection nuts 6 which can connect adjacent screws in series. The screw on the inner side of the screw connection nut at one end is provided with a fixed disc 8, which can be connected to the screw as a whole, and the screw on the inner side of the screw connection nut at the other end is equipped with a sliding umbrella disc 4 and an adjustment that can push the sliding umbrella disc to move on the screw For the nut 5, the connecting surface between the sliding umbrella plate and the adjusting nut is an axial connecting surface, for example, a clamping edge and a clamping groove are adopted for the axial connection.

[0015] One ends of the plurality of second supporting rods are pivotally connected to the outer peripheral wall of the fixed plate at an interval dist...

Embodiment 2

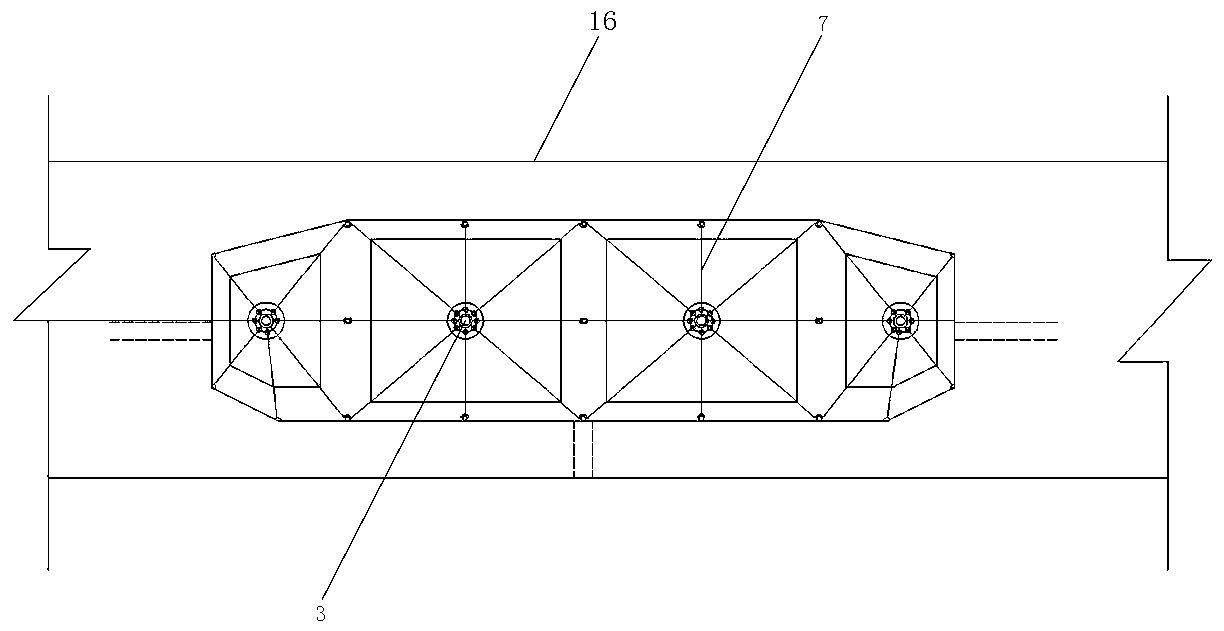

[0020] Example 2: Such as Figure 4 As shown, a telescopic support system for building construction includes a screw 3, a hydraulic cylinder 10, a first support rod 7 and a second support rod 9. The steel pipe body 13 is provided with a plurality of strip chutes 14 at intervals in the transverse direction and the longitudinal direction. The axis lines of the longitudinally corresponding strip chutes on the steel pipe body are the same. A sliding rod 12 is provided on the longitudinal axis of the steel tube. One end of the steel pipe body is provided with a hydraulic cylinder, and the end surface of the hydraulic telescopic rod 11 is connected to one end of the sliding rod located in the steel pipe body. An end of the second support rod 9 is axially connected to the outer wall of the steel pipe corresponding to the upper end of the strip chute. One end of the first rod is axially connected with the corresponding sliding rod part located in the bar-shaped sliding groove. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com