A kind of hydraulic system of AGV trolley, trolley and working method thereof

A hydraulic system and trolley technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve problems such as difficult to accurately move horizontally and vertically and on curved tracks, cannot be used for vehicle transportation, and lack of flexibility. Compact, easy to function, and avoid damage to the mechanical mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

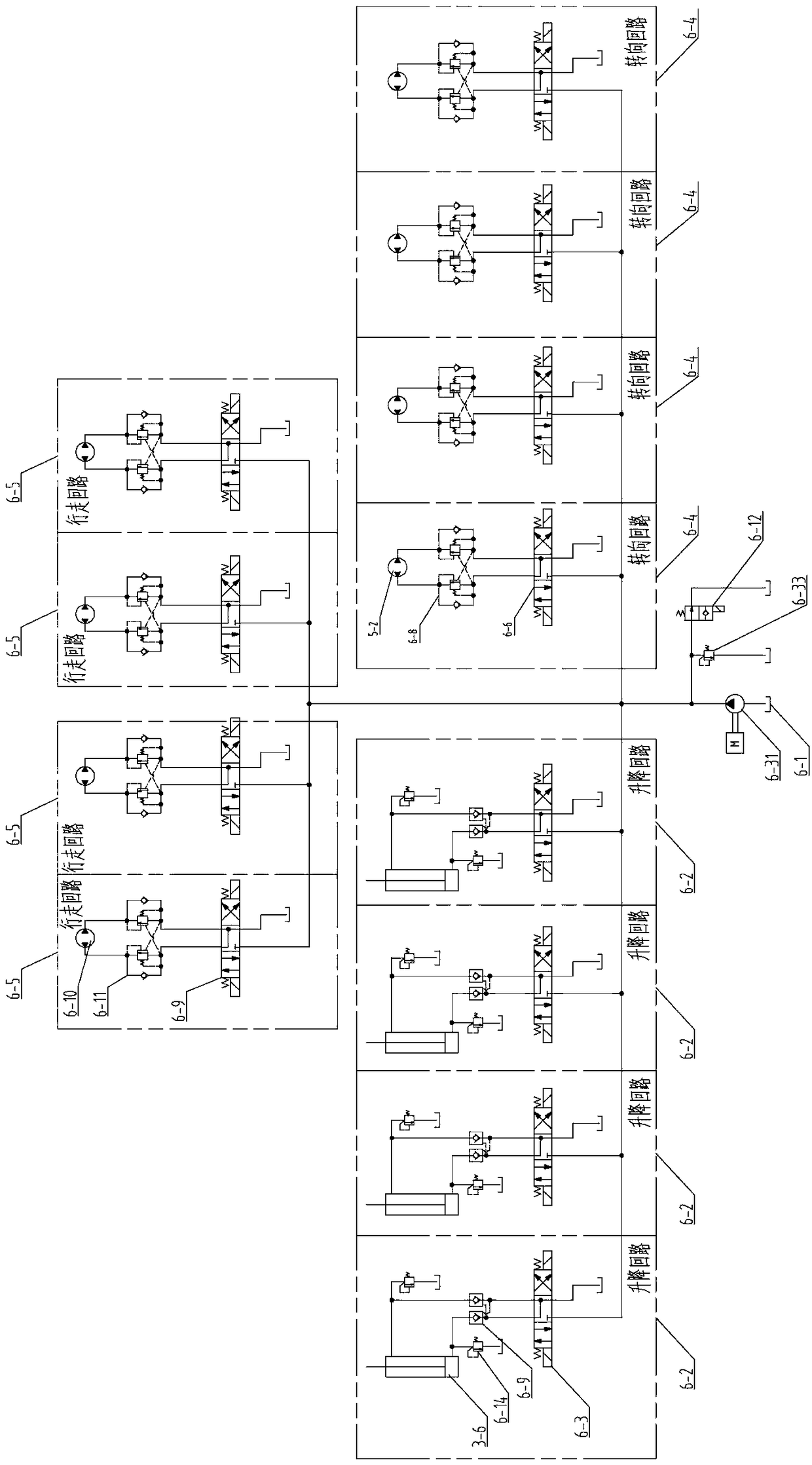

Method used

Image

Examples

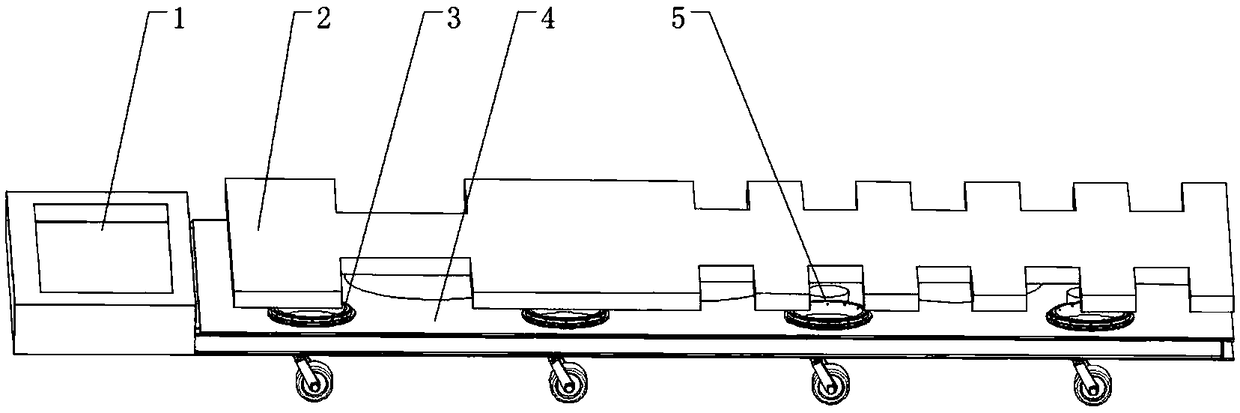

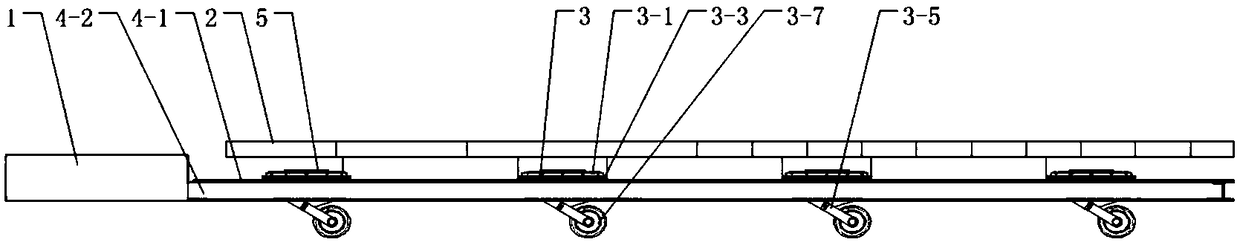

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail, but the scope of protection of the present invention is not limited to the following examples, all technical schemes obtained by adopting equivalent replacement or equivalent transformation forms are all within the scope of protection of the present invention .

[0032] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical terms and scientific terms) used in the present invention have the same meaning as commonly understood by those of ordinary skill in the art to which the present invention belongs.

[0033] The meaning of "inside and outside" in the present invention means that when the reader is facing the drawings, the direction pointing to the inside of the trolley is inward, and vice versa is outward, and it is not a specific limitation to the trolley of the present invention.

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com