Drying box for precision casting

A technology of precision casting and drying oven, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of concave deformation, high strength, and insufficient hot air circulation on the surface of the mold, so as to achieve matching flow and difficult to fit. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] Such as Figure 1-Figure 5 Shown, the present invention provides a kind of technical scheme of precision casting drying box:

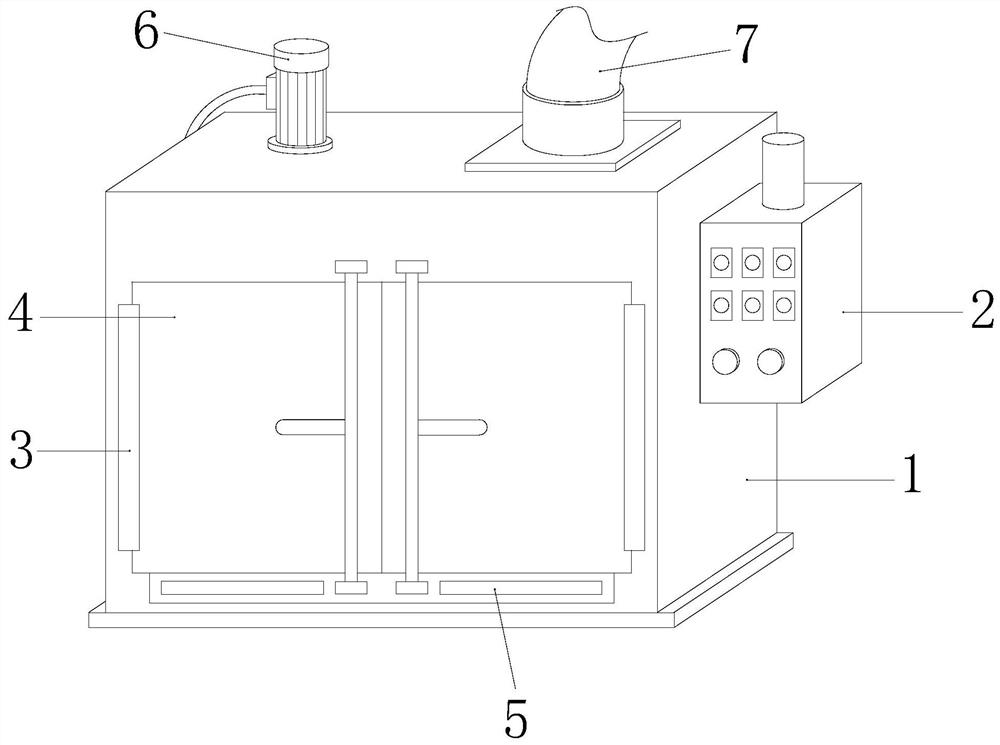

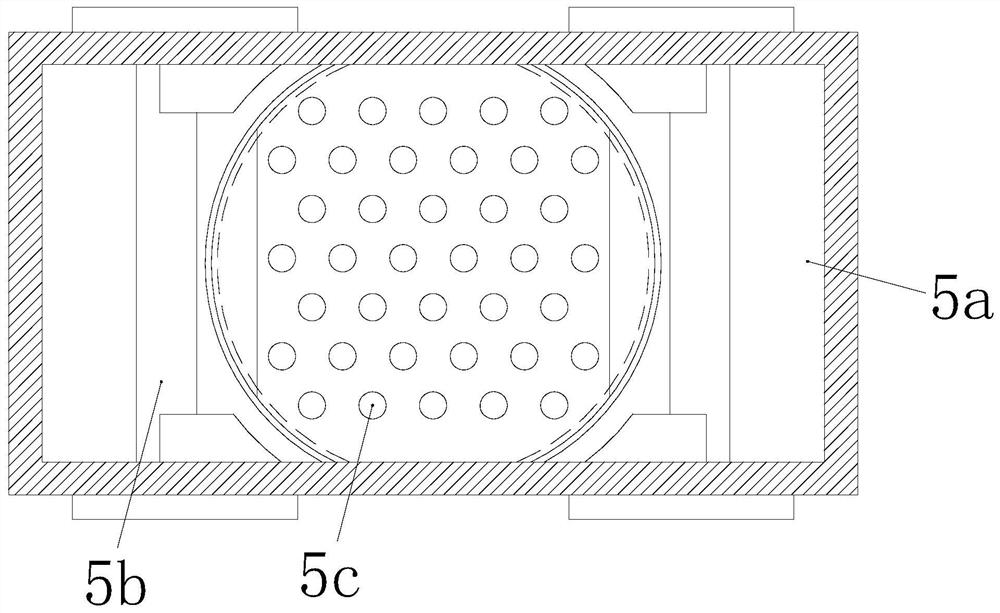

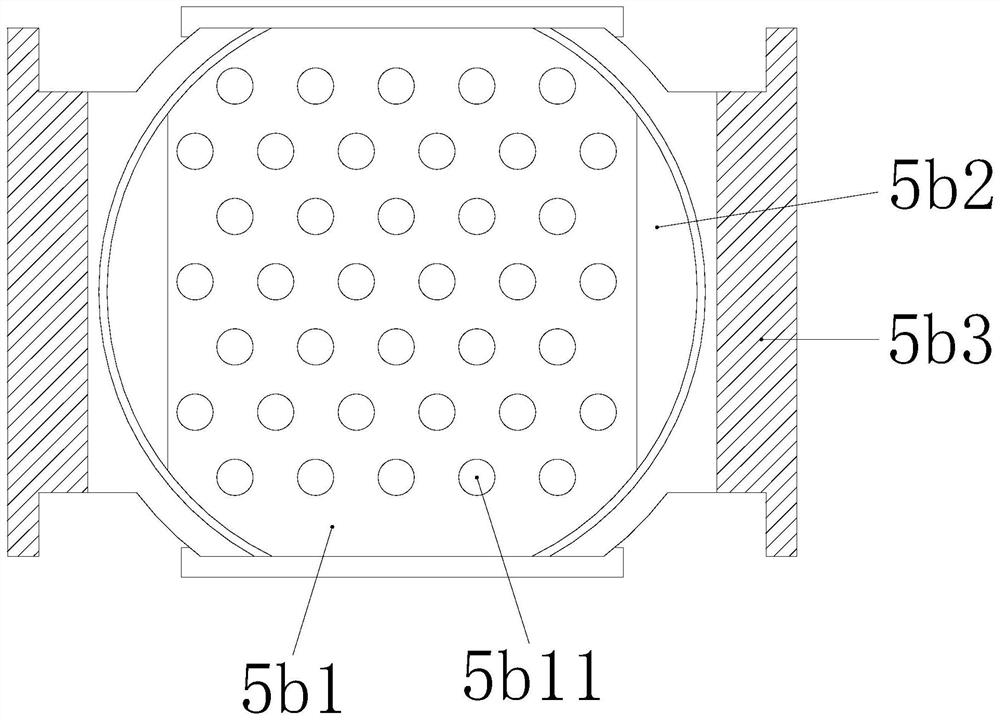

[0031] Such as Figure 1-Figure 2 As shown, a drying box for precision casting, its structure includes a device main body 1, a controller 2, a sealed door 3, a drying chamber 4, a shape protection device 5, a driving motor 6, and an exhaust pipe 7, and the controller 2 is set On the right side surface of the equipment main body 1 and connected by electric welding, the airtight door 3 is set on the front surface of the equipment main body 1 and connected by hinges, and the drying chamber 4 is set inside the equipment main body 1 and corresponding to the airtight door 3 , the shape protection device 5 is arranged at the bottom of the drying chamber 4 and is connected by rail sliding, the driving motor 6 is arranged on the upper surface of the equipment main body 1 and is electrically connected, and the exhaust pipe 7 is arranged on the upper surf...

no. 2 example

[0041] Such as figure 1 , figure 2 , Image 6 , Figure 7 , Figure 8 Shown, the present invention provides a kind of technical scheme of precision casting drying box:

[0042] Such as Figure 1-Figure 2 As shown, a drying box for precision casting, its structure includes a device main body 1, a controller 2, a sealed door 3, a drying chamber 4, a shape protection device 5, a driving motor 6, and an exhaust pipe 7, and the controller 2 is set On the right side surface of the equipment main body 1 and connected by electric welding, the airtight door 3 is set on the front surface of the equipment main body 1 and connected by hinges, and the drying chamber 4 is set inside the equipment main body 1 and corresponding to the airtight door 3 , the shape protection device 5 is arranged at the bottom of the drying chamber 4 and is connected by rail sliding, the driving motor 6 is arranged on the upper surface of the equipment main body 1 and is electrically connected, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com