Characterization method for porous structure of regenerated cellulose material

A regenerated cellulose and characterization technology, applied in the field of fiber characterization, can solve the problems of sample damage results, untrue reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, to the characterization of the pore structure of viscose fiber

[0042] First, soak the regenerated cellulose material:

[0043] (1) Take a certain amount of viscose fiber and place it in N,N-dimethylacetamide (DMAc) solution;

[0044] (2) placed in a shaker and shaken at room temperature 25°C for 7 days;

[0045] (3) After the sample was taken out, the content of DMAc in the sample was determined to be 89% by thermogravimetric analysis.

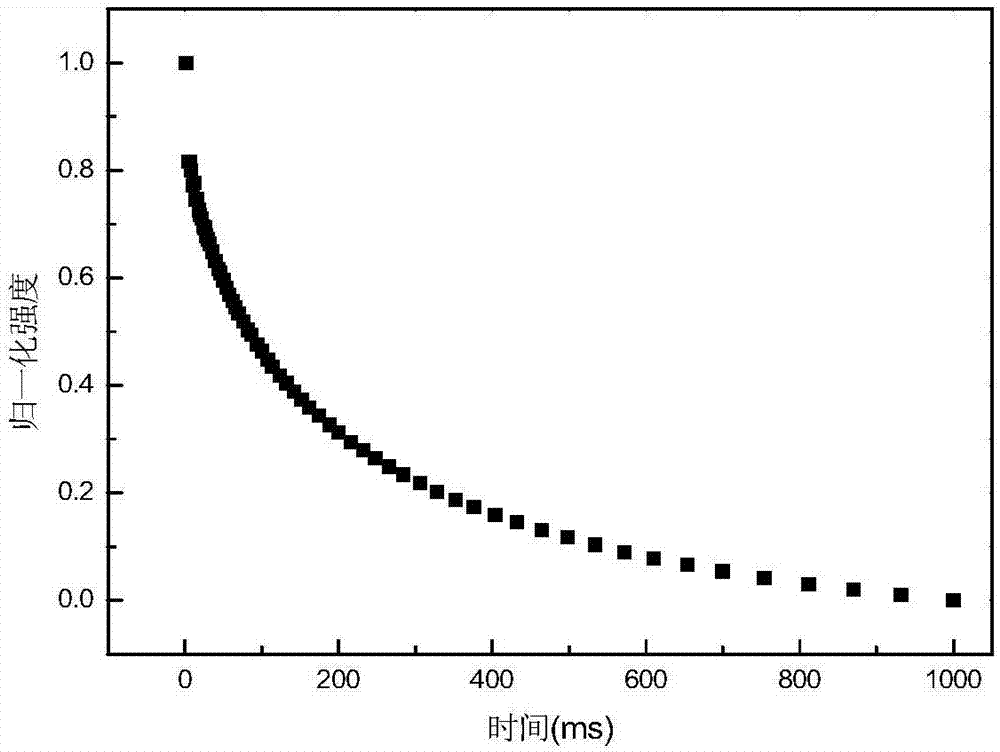

[0046] The samples were then tested by hydrogen nuclear magnetic relaxation spectroscopy.

[0047] The CPMG pulse sequence is used in the test, the test temperature is 25°C, the echo time is 1ms, and the number of sampling points is 100.

[0048] Export the NMR relaxation data as figure 1 As shown, using the inverse Laplace formula (1), the fitting is carried out on Matlab software.

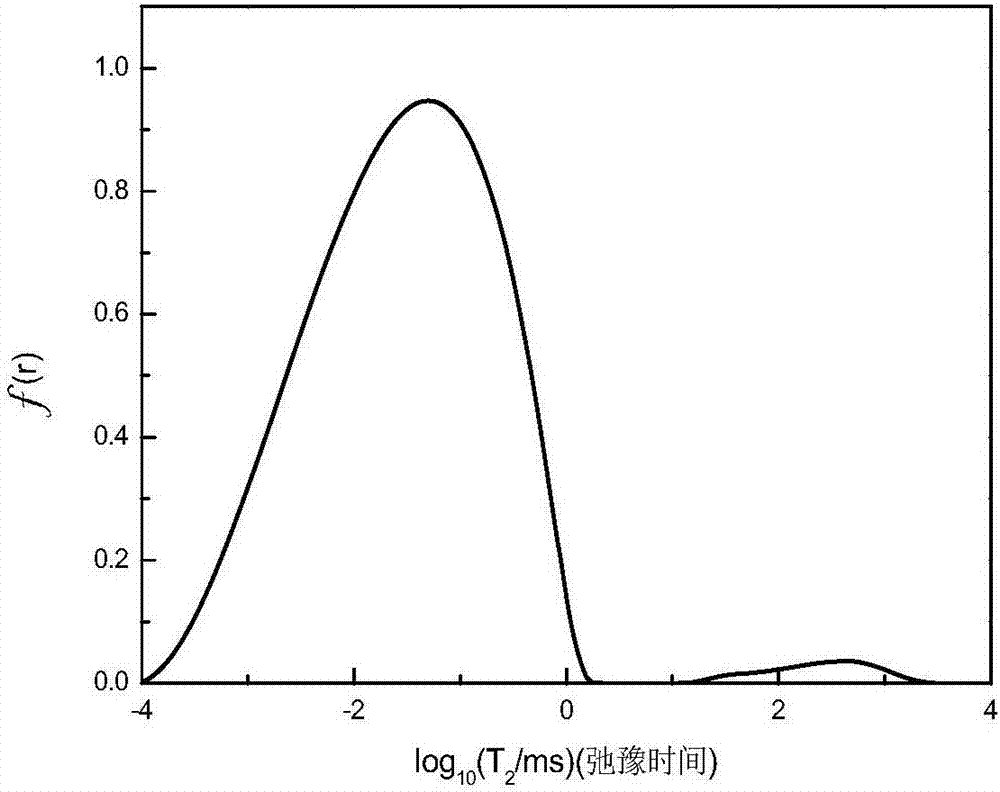

[0049] The fitting results are as figure 2 shown.

[0050] figure 2 The abscissa in represents the logarithm of the relaxation t...

Embodiment 2

[0051] Embodiment 2, the characterization of the pore structure of regenerated cellulose hydrogel

[0052] First, soak the regenerated cellulose material:

[0053] (1) Get a certain amount of cotton linter pulp (cellulose, provided by Hubei Chemical Fiber Group Co., Ltd.), dissolve the cotton linter pulp in NaOH / urea aqueous solution and let it stand to form a hydrogel, soak it in H at room temperature 2 O middle;

[0054](2) placed in a shaker and shaken at room temperature for 7 days;

[0055] (3) After the sample was taken out, it was determined by thermogravimetric analysis that the H in the sample was 2 The content of O is 85%.

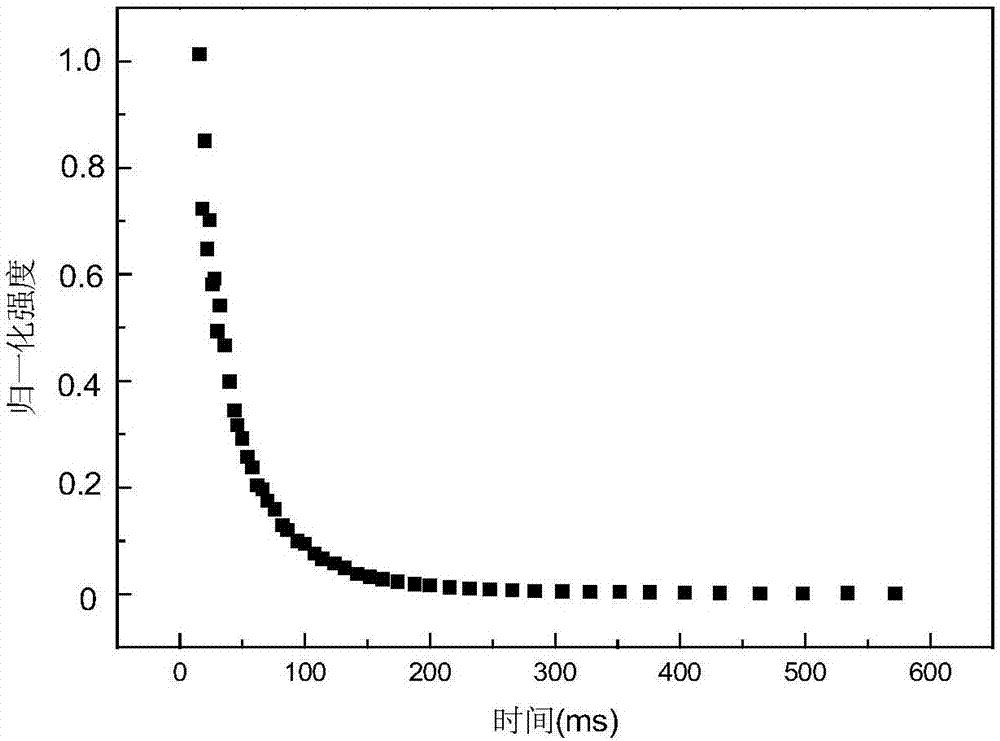

[0056] The samples were then tested by hydrogen nuclear magnetic relaxation spectroscopy.

[0057] The CPMG pulse sequence is used in the test, the test temperature is 25°C, the echo time is 1ms, and the number of sampling points is 56.

[0058] Export the NMR relaxation data as image 3 As shown, using the inverse Laplace formula (1), the ...

Embodiment 3

[0061] Embodiment 3, the characterization of the hole structure of polyphosphoric acid solution regenerated fiber

[0062] First, soak the regenerated cellulose material:

[0063] (1) Get a certain amount of polyphosphoric acid solution regenerated fiber, soak in DMAc at room temperature;

[0064] (2) placed in a shaker and shaken at room temperature for 7 days;

[0065] (3) After the sample was taken out, the content of DMAc in the sample was determined to be 89% by thermogravimetric analysis.

[0066] The samples were then tested by hydrogen nuclear magnetic relaxation spectroscopy.

[0067] The CPMG pulse sequence is used in the test, the test temperature is 25°C, the echo time is 1ms, and the number of sampling points is 100.

[0068] Export the NMR relaxation data as Figure 5 As shown, using the inverse Laplace formula (1), the fitting is carried out on Matlab software.

[0069] The fitting results are as Figure 6 shown.

[0070] Depend on Figure 6 It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com