Catalyst gauze and installation for the catalytic oxidation of ammonia

A catalytic net, ammonia oxidation technology, applied in the direction of heterogeneous catalyst chemical elements, nitric oxide, chemical instruments and methods, etc., can solve the problems of poor flow distribution, ammonia slip, failure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

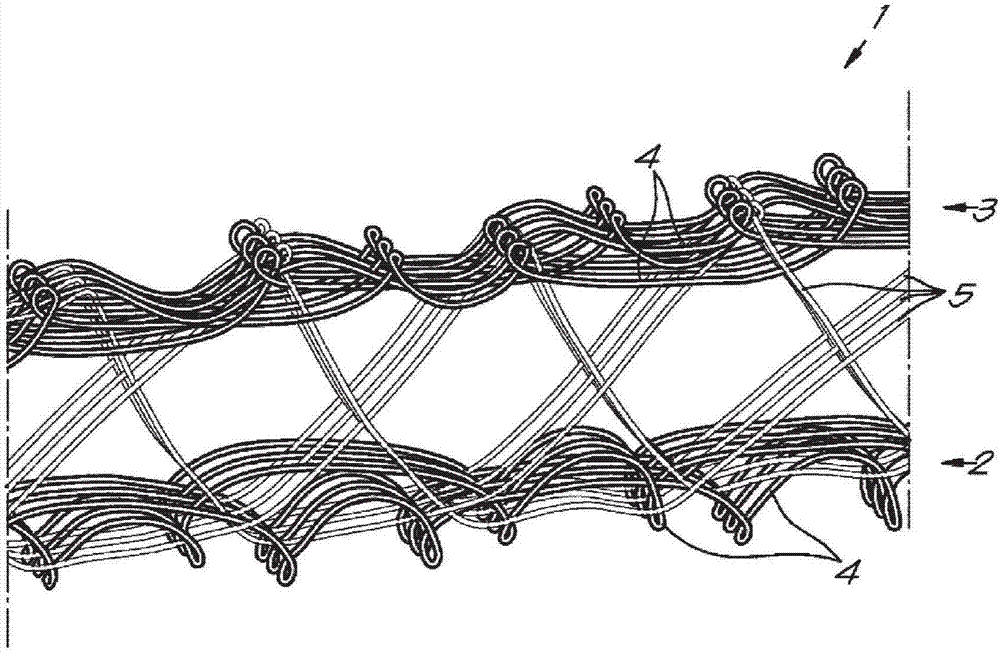

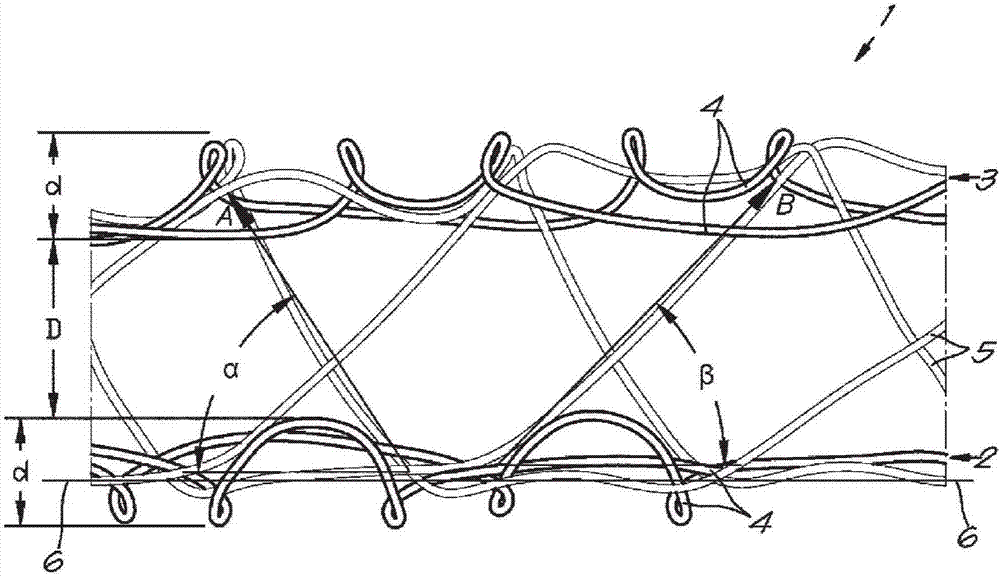

[0034] The catalytic net 1 in the accompanying drawings is mainly composed of two layers, more specifically, a first layer 2 and a second layer 3, both of which are knitted.

[0035] The first layer 2 is made of a first mesh 4, which in this example, but not necessarily, has a diameter of 0.076 mm and is composed of 81.5% by weight Pd, 15% by weight Pt and 3.5% by weight Made of alloys composed of Rh. In this example, but not necessarily, the second layer 3 is made of the same mesh material as the first layer 2 .

[0036] The first layer 2 and the second layer 3 have a thickness d of about 0.55mm and are placed at a distance D of about 1.4mm, forming an overall thickness D+2d of 2.5mm.

[0037] Between the stitches of the knitted mesh 4 of the first layer 2 and the second layer 3 , pile yarns 5 are arranged, which shuttle back and forth between the first layer 2 and the second layer 3 . The pile yarn 5 is made of a second mesh, which in this example, but not necessarily, has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com