Method for motion simulation of a manipulator

A motion simulation and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, general control systems, etc., can solve the problems of manipulator components or manufacturing unit damage, long manufacturing unit accident time, high risk of collision, etc., to improve ergonomics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

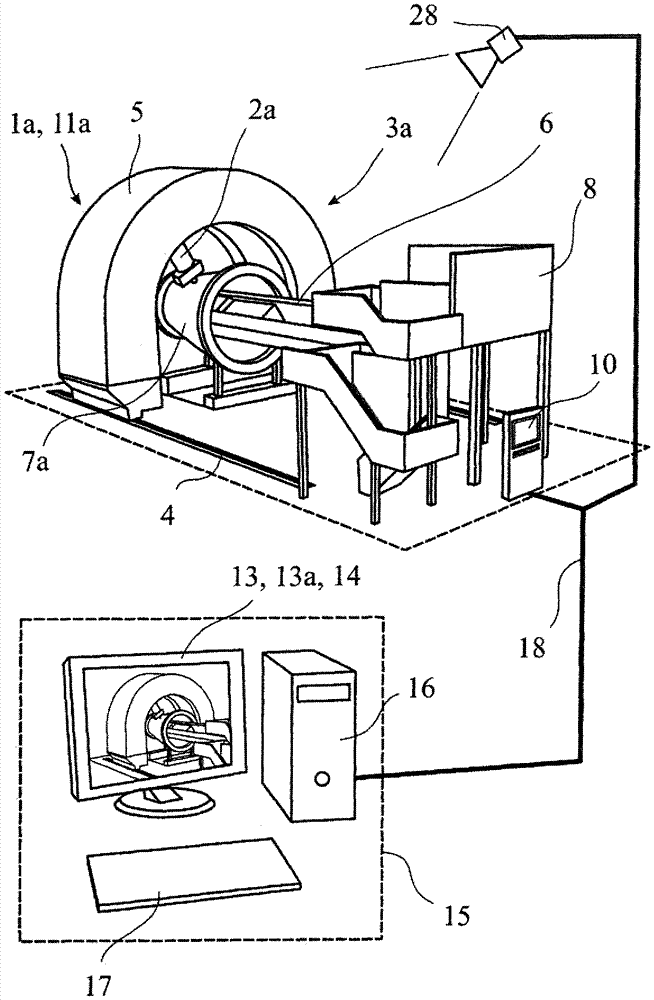

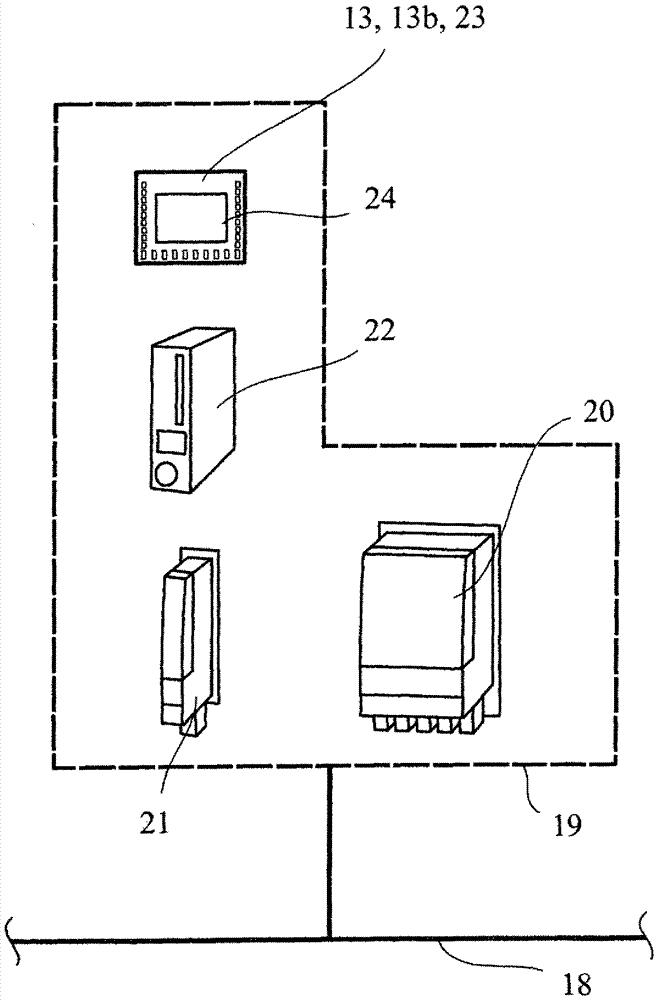

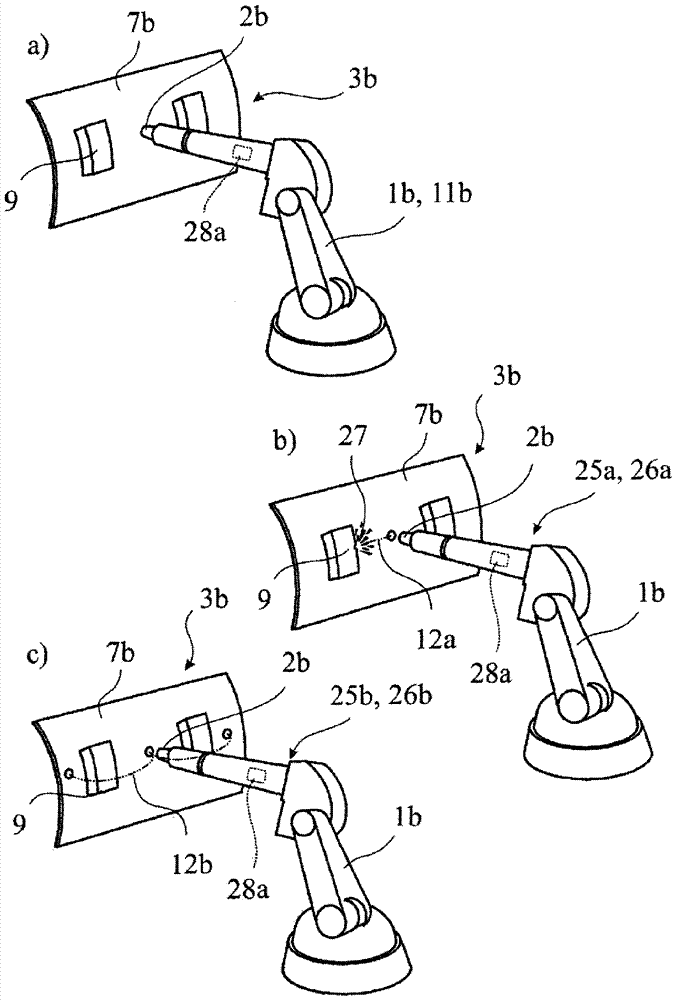

[0043] The exemplary embodiment described here relates to a robot 1a,b in a manufacturing cell in which riveting is produced on an aircraft structural component by means of a riveting device. Manipulators 1a, b are NC controlled. exist figure 1 The manufacturing cell of the first embodiment shown in is an Integrated Section Assembly Cell for machining 360°-aircraft fuselage components. The riveting device forms the end effector 2a of the manipulator 1a, which is here a 12-axis positioning machine. The production cells of the two exemplary embodiments, including all their associated components, respectively form a processing environment 3a, 3b in the sense of the above-mentioned definitions of the terms.

[0044] The end effector 2a is able to move on the inner surface of the processing arch 5 which moves along the floor rail 4, whereby the arch rail 4 and the processing arch 5 respectively form part not only of the processing environment 3a but also of the manipulator 1a. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com