Oxygen clathrate hydrate and oxygen solution containing the same

A clathrate hydrate and solution technology, which is applied in the fields of dissolution, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve problems such as no increase in blood oxygen saturation value observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Determination of Dissolved Oxygen Amount 2

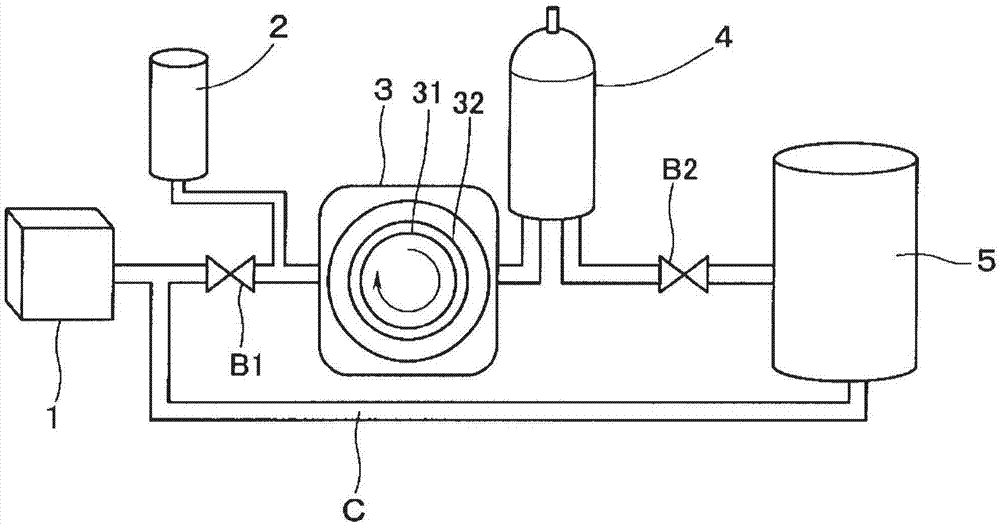

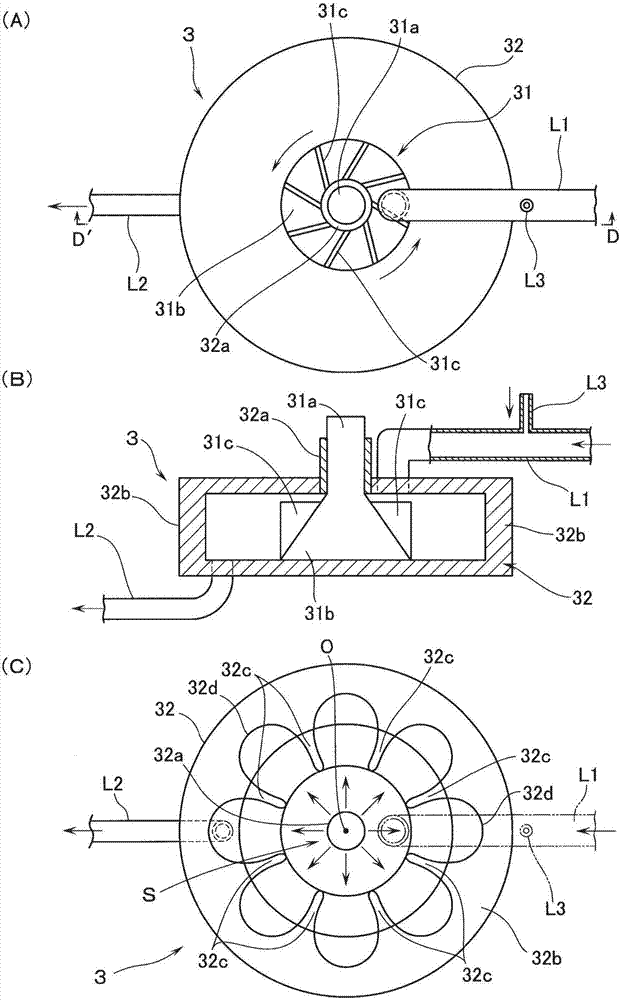

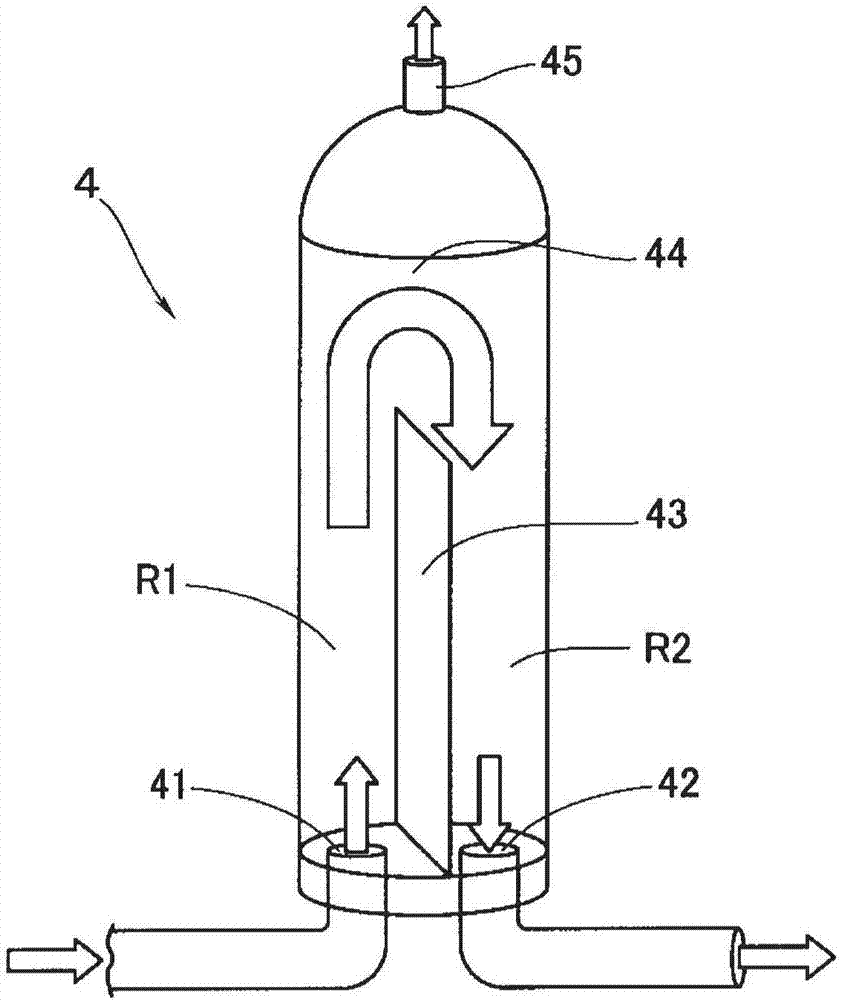

[0108] Use Figure 1 ~ Figure 3 The illustrated oxygen-containing water production system produced oxygen-dissolved solutions (samples F to J). The amount of dissolved oxygen was measured for the dissolved oxygen solution (samples F to J) by the conventional diaphragm method, fluorescence method, Winkler method, and carbohydrazide method devised by the present inventors.

[0109] In the diaphragm method, a diaphragm type galvanic cell type oxygen concentration meter (manufactured by Toa Denpa Co., Ltd. (TOA DKK Corporation), DO-31P) was used.

[0110] In the carbohydrazide method, by using Figure 1 ~ Figure 3 Add carbohydrazide (0.1 g) as a deoxygenated amino compound to the oxygen dissolved solution (samples F to J, 500ml) produced by the oxygenated water production system described above, and heat at 80°C for 4 hours to make the oxygenated water The dissolved oxygen reacts with carbohydrazide. Next, after measuring th...

Embodiment 2

[0118] Study on the influence of heat treatment

[0119] (1) Test method

[0120] To use Figure 1 ~ Figure 3 The effect of heat treatment on oxygenated dissolved liquid produced by the illustrated oxygenated water production system was studied. Specifically, proceed through the following steps.

[0121] (a) Take 3 liters of the sample (oxygen dissolved solution) and place it in the Erlenmeyer flask, and measure the water temperature with a thermometer in the opened state.

[0122] (b) Put the asbestos net on the Cassette gas stove, place the Erlenmeyer flask with the sample on it, and start heating.

[0123] (c) After about 35 to 40 minutes, the temperature of the sample reaches 100°C. Heating was stopped 3 minutes after reaching 100° C., the flask was quickly removed from the gas stove, and the Erlenmeyer flask was cooled with tap water. Cool for about 20 minutes, take it out when the water temperature drops to 20°C, and let it stand.

[0124] (e) Fill all of it into ...

Embodiment 3

[0131] Research on the effect of promoting growth of plants

[0132] Prepare the following three kinds of water and oxygen solution 1, 2.

[0133](1) RO water obtained through a reverse osmosis membrane (DO value: 9.4ppm / CH value: 9.5ppm).

[0134] (2) Oxygen solution 1 (DO value: 13.1 ppm / CH value: 68.0 ppm) obtained in Example 2 after heating (100° C., 3 minutes).

[0135] (3) Oxygen solution 2 produced by setting the pressure of the gas-liquid mixing pump lower than that of Example 2 (DO value after heating (100°C, 3 minutes): 4.1ppm / CH value: 54.3ppm ).

[0136] Next, the seeds of sweet basil were sprinkled on the sponge of the cultivation device using a commercially available hydroponic cultivation device, and the liquid fertilizer was mixed with the above-mentioned RO water and oxygen solution 1 and 2, and cultivated (room temperature 10° C. to 20° C.). In addition, observe the water level through the water level buoy, and add the above-mentioned RO water and oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com