Thin lightweight woven fabric

A fabric, lightweight technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problem of no specified air permeability, can not meet the oblique deformation air permeability and other problems, and achieve the effect of excellent velvet resistance and low air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0055] Hereinafter, the present invention will be specifically described using experimental examples and the like.

[0056] In the following experimental examples and the like, the following measurement and evaluation methods, devices, and the like were used.

[0057] (1) Air permeability

[0058] Measured by JIS-L-1096 8.27.1A method (Fraser method). The unit is cc / cm 2 ·Second.

[0059] (2) Determination of air permeability after oblique deformation

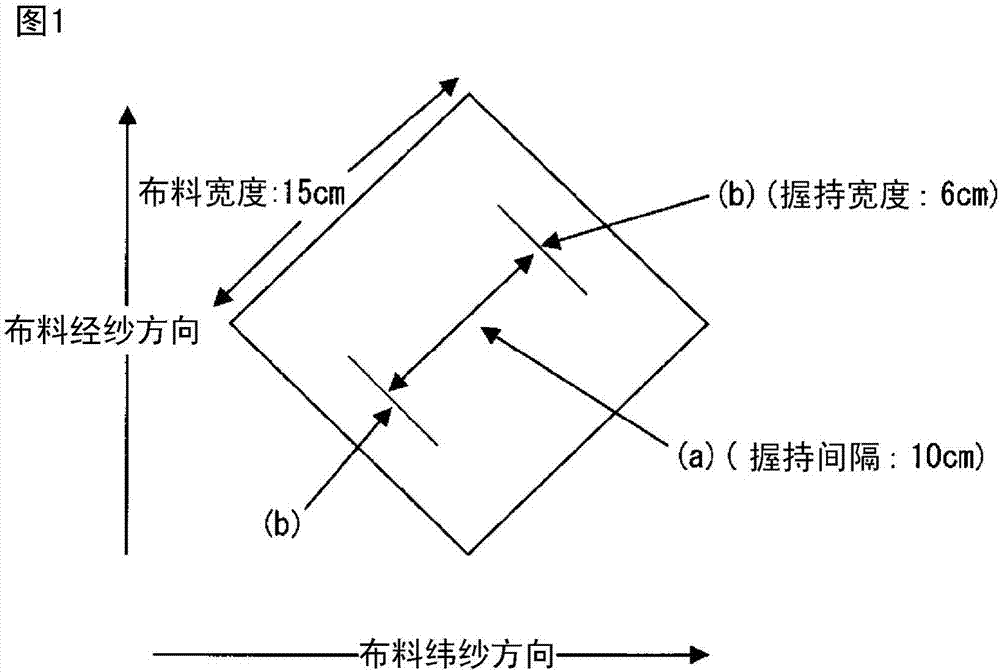

[0060] Such as figure 1 As shown, the sample was cut obliquely to 15 cm x 15 cm, and the air permeability was obtained by the same measurement method as in (1) above after deforming the sample under the following conditions using TENSILON RTC-1210A manufactured by ORIENTEC Corporation.

[0061] Grip interval (a): 10cm

[0062] Grip width (b): 6cm

[0063] Cloth load: After applying the load to 2.25kgf, restore it.

[0064] Tensile speed: 30mm / min

[0065] (3) Weight per unit area

[0066] Calculated from the mass per...

experiment example 1

[0072] Nylon 6 filaments with 22 decitex 24 filaments (TG47°C, TM225°C) are used for the warp, and nylon 6 filaments with 33 decitex 26 filaments (TG47°C, TM225°C) are used for the weft, and the taffeta is made by a water jet loom Silk fabric. The obtained fabric was refined and pre-set by the usual method, dyed and dried with a liquid flow dyeing machine, and Nikka Chemical Co., Ltd.’s Nikkasilicon DM-100E 1% and anionic surfactant were used as the modified silicone resin. The emulsion with 0.5% agent was processed by DIP-NIP method. After drying at 140°C, the calendering temperature was 160°C and the calendering pressure was 300kgf (=300×9.807N) / cm (roll width 160 cm, cloth width 150 cm, therefore P = 48 (t / cloth width 150 cm)), calendering speed 15 m / min hot calendering. The attached amount of the silicone resin was 0.8 wt%.

[0073] Regarding the properties of the obtained fabric, the cover factor was 1801, the degree of overlap was 0.80 in length and 0.50 in width, an...

experiment example 2

[0075] Nylon 6 filaments of 22 decitex 24 filaments (TG47°C, TM225°C) were used for the warp, and nylon 6 filaments of 33 decitex 26 filaments (TG47°C, TM225°C) were used for the weft, and the grid was produced in the same manner as in Experimental Example 1. Taffeta fabric and processing.

[0076] Regarding the properties of the obtained fabric, the cover factor was 1953, the degree of overlap was 0.85 in length and 0.60 in width, and the weight per unit area of the fabric was 45 g / m 2 , the tear strength is 16N in warp and 16N in weft, and the air permeability is 0.8cm 2 ·Second. In addition, the air permeability after the oblique deformation measurement method is 0.9cc / cm 2 ·Second.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com