Exhaust gas purification system for internal combustion engine, internal combustion engine, and exhaust gas purification method for internal combustion engine

A technology of exhaust gas and purification system, which is applied to the exhaust gas purification system of internal combustion engines, the field of internal combustion engines and the exhaust gas purification of internal combustion engines, and achieves the effects of suppressing thermal deterioration, high NOx purification rate, and excellent robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

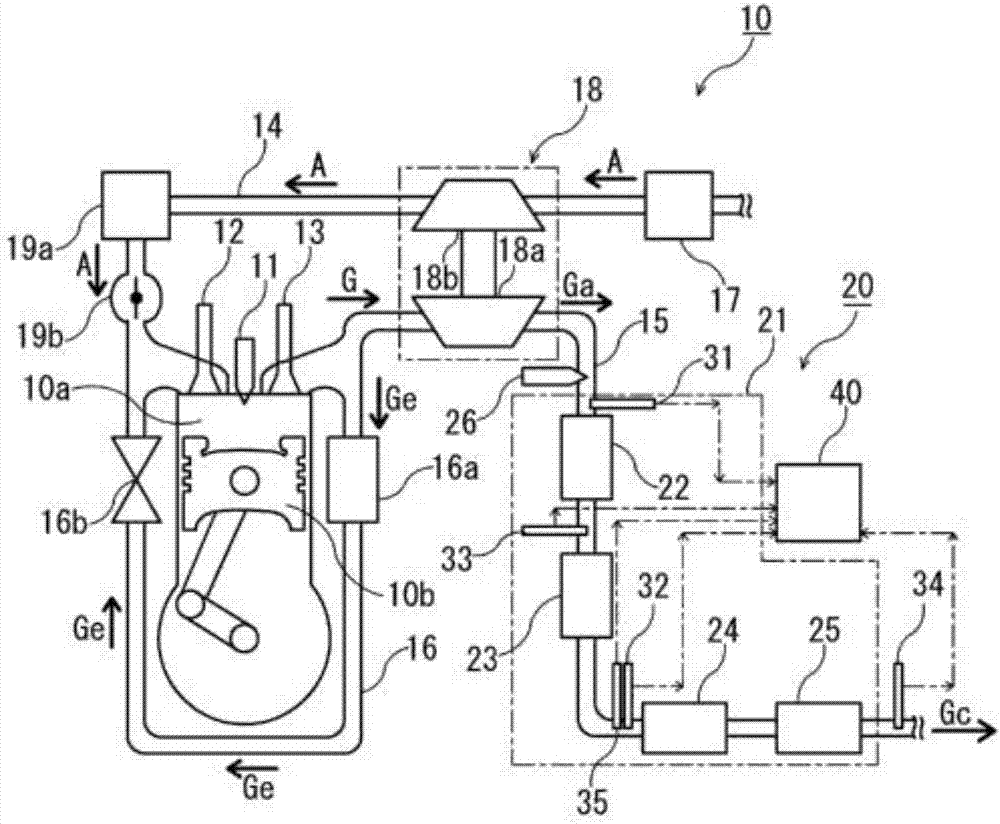

[0033] Hereinafter, an exhaust gas purification system for an internal combustion engine, an internal combustion engine, and an exhaust gas purification method for an internal combustion engine according to embodiments of the present invention will be described with reference to the drawings. In addition, the internal combustion engine according to the embodiment of the present invention is configured to include the exhaust gas purification system of the internal combustion engine according to the embodiment of the present invention, and can achieve the same function and effect as the exhaust gas purification system of the internal combustion engine described below. .

[0034] First, refer to figure 1 , an internal combustion engine (hereinafter referred to as an engine) 10 and an exhaust gas purification system 20 for the internal combustion engine according to an embodiment of the present invention will be described. In this engine 10, a fuel injection device 11, an intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com