Preparation method for formed carbon ceramic used for adsorbing humic acid

A technology of humic acid and ceramics, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of eye irritation and corrosion, and achieve adsorption performance Good, good molding effect, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

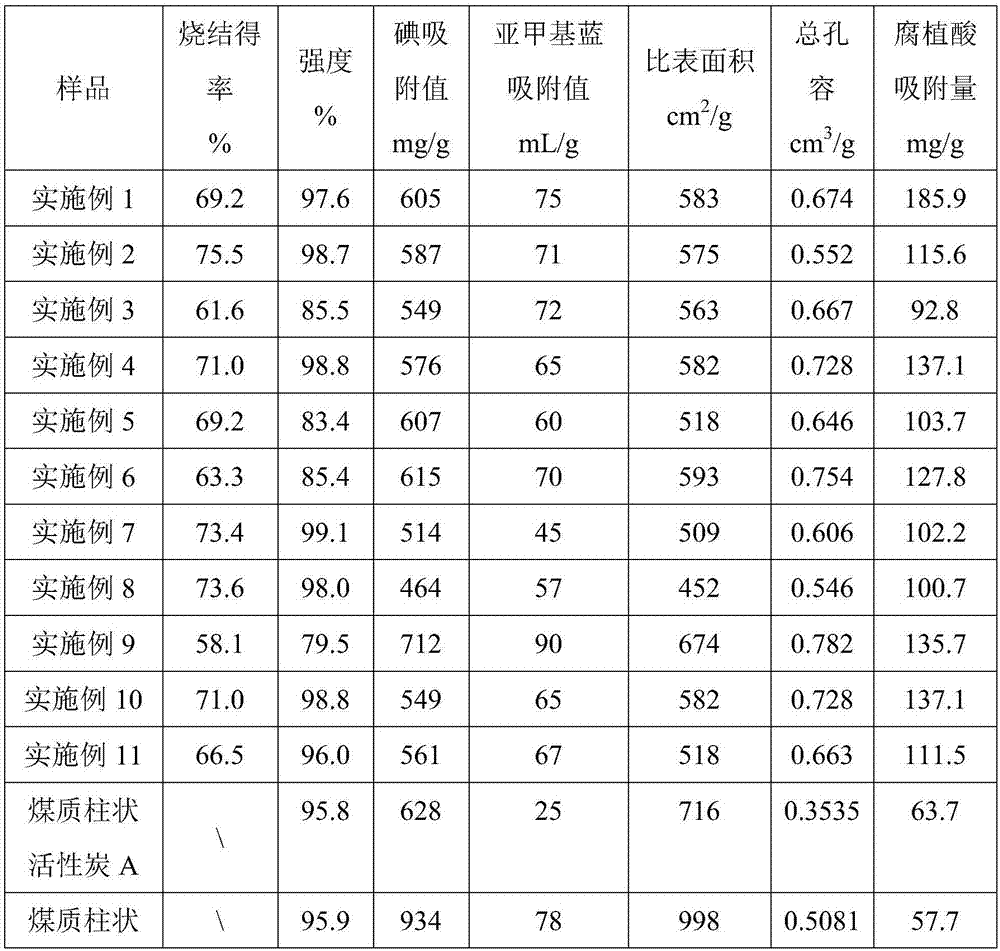

Embodiment 1

[0022] Mix the attapulgite that has been crushed and sieved to more than 120 mesh with the waste powdered activated carbon crushed to more than 200 mesh at a mass ratio of 1:4, then add water, put it into a kneader for full mixing and kneading for 2 hours, Pour the above mixture into a mold for extrusion molding, put the extruded columnar carbon ceramic body in an oven at 110°C to dry for 4 hours, take it out, cool it to room temperature, and heat up at a rate of 5°C / min Heating to 800°C, keeping it warm for 2 hours, and taking it out after cooling down to room temperature to obtain columnar carbon ceramics. Its performance is shown in Table 1.

Embodiment 2

[0024] Mix attapulgite that has been crushed and sieved to 120 mesh with charcoal crushed to 200 mesh or more in a mass ratio of 1:3, then add water, put it into a kneader for full mixing and kneading for 1 hour, pour the above mixture into In the mold, carry out extrusion molding, put the extruded columnar carbon ceramic green body into an oven at 110°C to dry for 4 hours, take it out, cool it to room temperature, heat it to 800°C at a heating rate of 5°C / min, and keep it warm. After 2 hours, take it out after cooling down to room temperature to obtain columnar carbon ceramics. Its performance is shown in Table 1.

Embodiment 3

[0026] Mix the attapulgite that has been crushed and sieved to more than 200 mesh with the waste powdered activated carbon crushed to more than 200 mesh at a mass ratio of 1:2, then add water, put it into a kneader for full mixing and kneading for 1 hour, Pour the above mixture into a mold for extrusion molding, put the extruded columnar carbon ceramic green body in an oven at 110°C for drying, take it out, then heat it to 800°C at a heating rate of 5°C / min, and keep it warm for 2 hours , and take it out after it drops to room temperature to obtain columnar carbon ceramics. Its performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com