Cleaning and air drying system for television set back plate stamping part

A technology for TV sets and stamping parts, applied in the field of TV backplane technology, can solve the problems of waste of water resources, low cleaning efficiency, etc., and achieve the effects of full recycling and saving, simple structure, and reduced drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

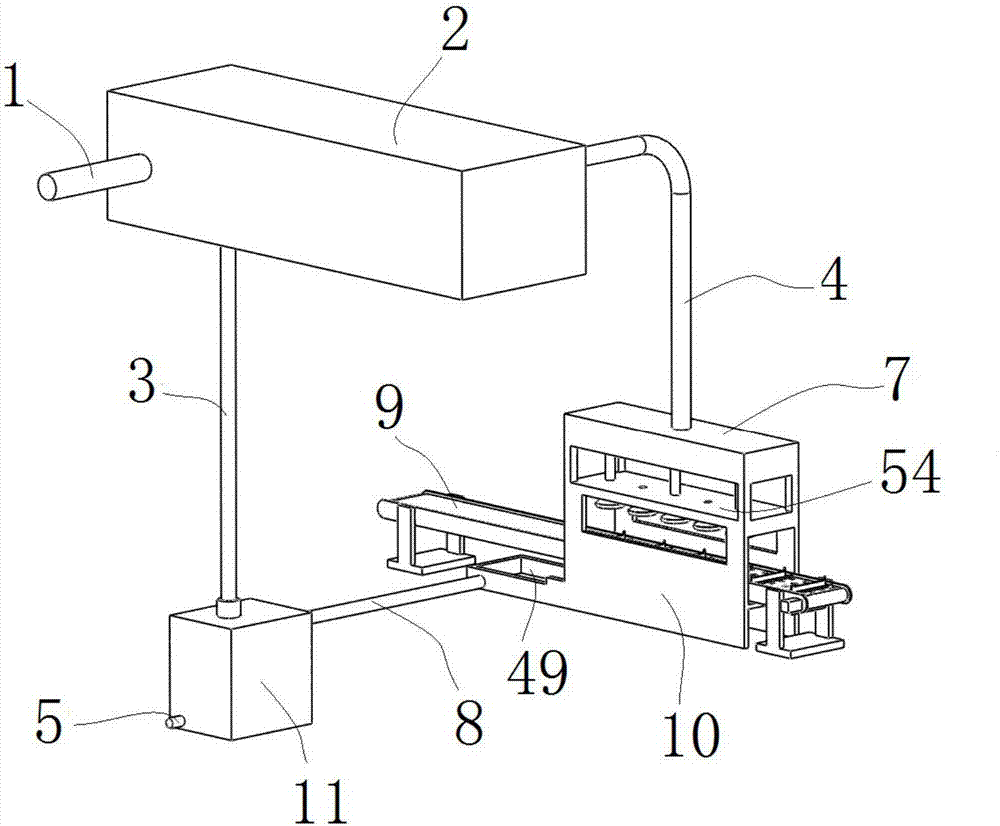

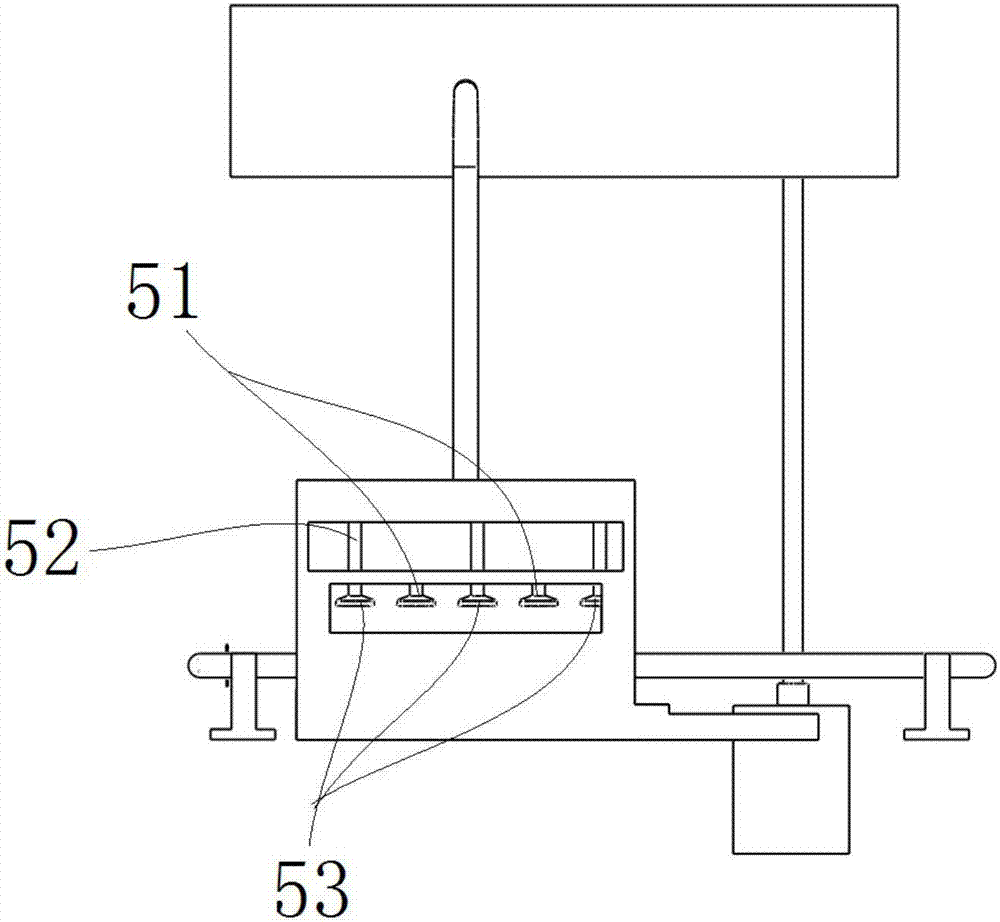

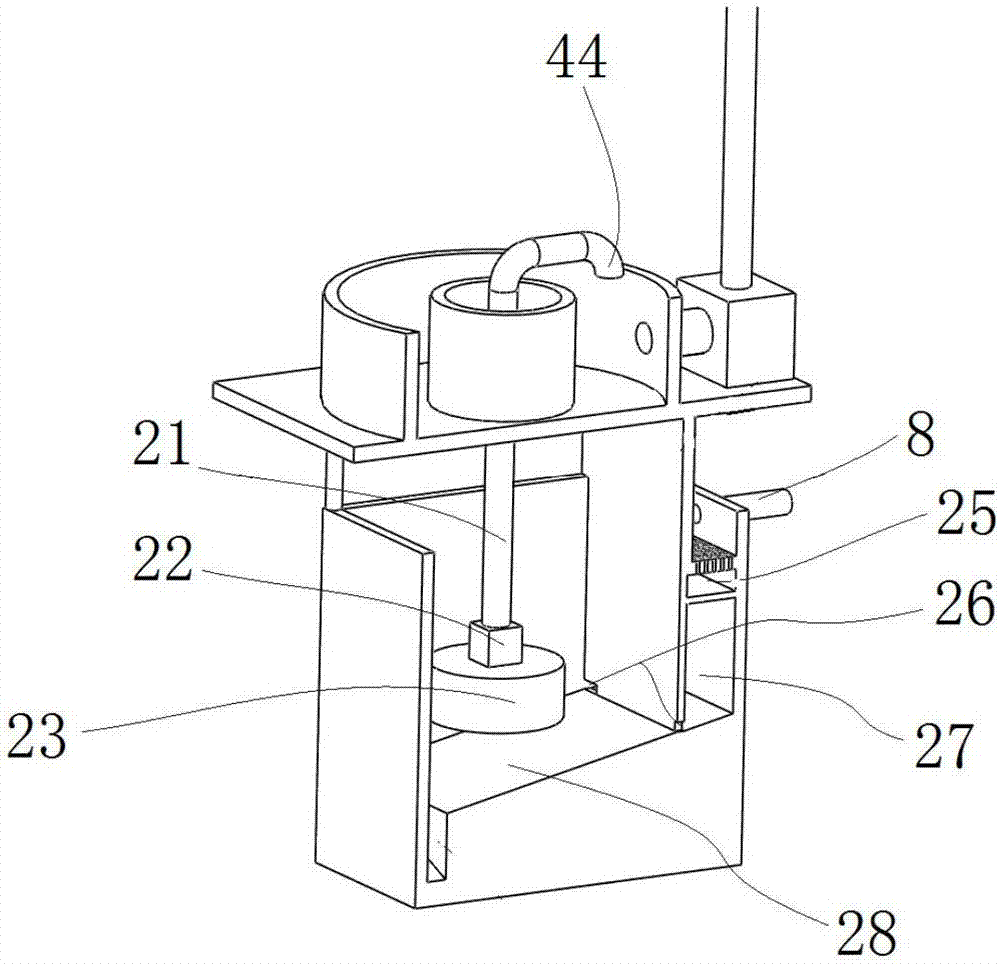

[0024] as attached Figures 1 to 5 As shown, the cleaning and air-drying system for stamping parts of the TV back panel is characterized in that it includes a TV back panel conveyor belt 9, a hot air blower 51, a shower 53, a diversion water tank 7, a top plate 54, a water guide slope 56 and a recovery water tank 49 Some of the hot air blowers 51 and showers 53 are arranged above the TV backboard conveyor belt 9, and some of the hot air blowers 51 and showers 53 are arranged alternately, and the hot air blowers 51 and showers 53 are arranged along the TV backboard The longitudinal direction of conveyor belt 9 is evenly distributed in array, and the air outlet of hot air blower 51 and the water spray port of shower 53 are set opposite to the transmission surface of the TV backplane conveyor belt 9 below, and the tops of some hot air blowers 51 and top plate 54 The supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com