Injection system of injection molding machine

An injection system and injection molding machine technology, applied in the field of injection systems of injection molding machines, can solve problems such as energy waste, nozzle salivation, and inability to filter out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a screw for an injection molding machine, which can be preferably used in various existing injection molding machines.

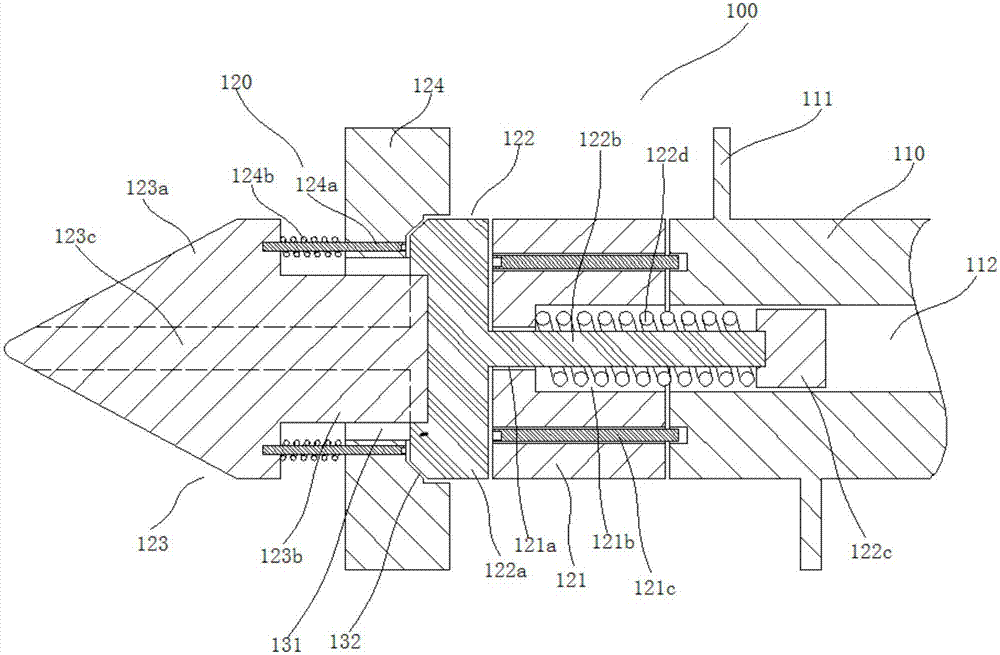

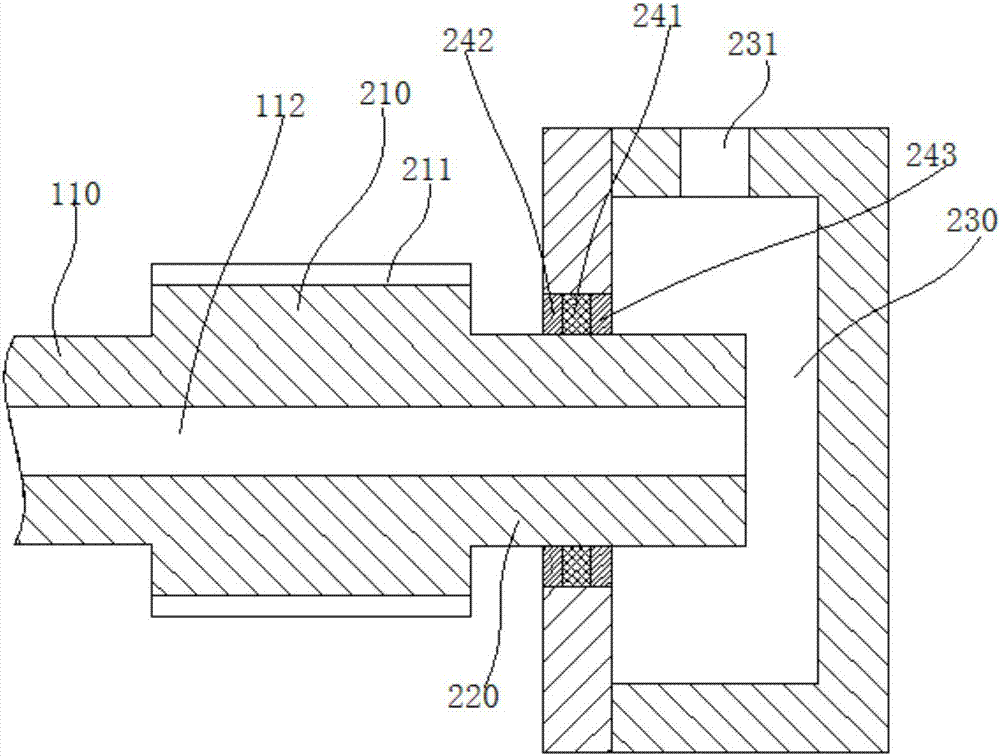

[0031] combine figure 1 As shown, a screw for an injection molding machine in this embodiment includes a screw body 100 , the screw body 100 includes a screw body 110 , the outer side of the screw body 110 is provided with a flight 111 , and the inside of the screw body 110 is provided with a hydraulic channel 112 penetrating in the axial direction; The left end of the screw body 110 is provided with a screw head 120, and the screw head 120 includes a mounting seat 121, a screw head seat 122, a screw head body 123 and a check ring 124; The hydraulic channel 112 is coaxially provided with an installation channel 121a, and the installation channel 121a expands to the outer periphery near the screw head main body 123 to form a spring cavity 121b; There is a screw head connecting rod 122b, and the screw head connecting rod 122b s...

Embodiment 2

[0042] This embodiment provides a nozzle structure for an injection molding machine, which can be preferably applied to various existing injection molding machines.

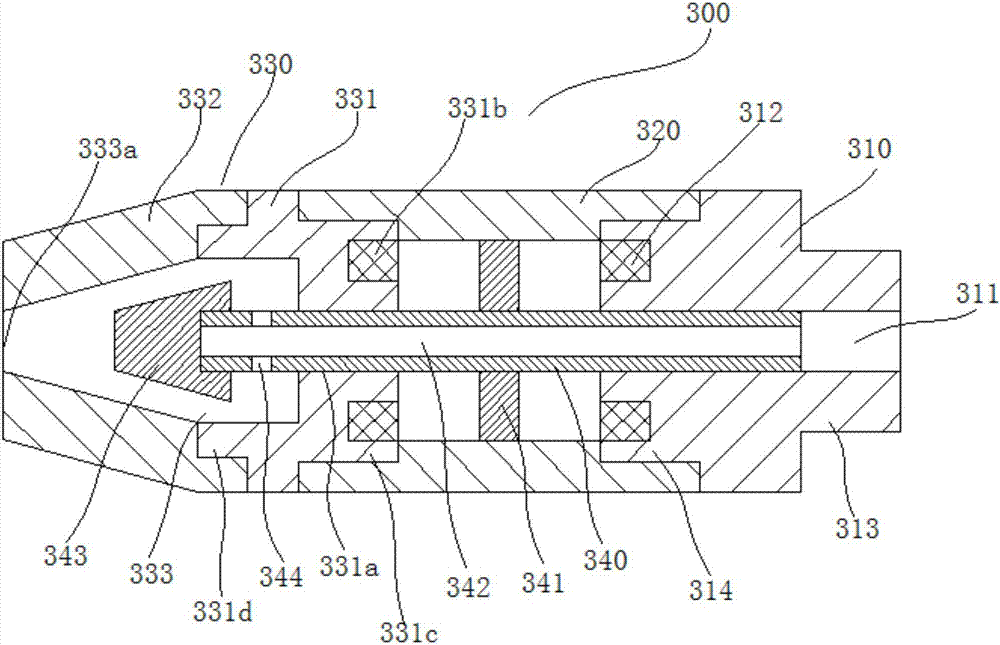

[0043] Such as image 3 As shown, a nozzle structure for an injection molding machine in this embodiment includes a nozzle body 300 .

[0044] Wherein, the nozzle body 300 includes a nozzle seat 310, the left side of the nozzle seat 310 is connected with a hollow connecting sleeve 320, and the left side of the hollow connecting sleeve 320 is connected with a nozzle head 330; the nozzle head 330 includes a nozzle head mounting seat 331 and a nozzle cover 332, the nozzle head mounting seat 331 is connected with the hollow connecting sleeve 320, and the nozzle cover 332 is located at the nozzle head mounting seat 331;

[0045] The nozzle seat 310 and the middle part of the nozzle head mounting seat 331 are coaxially provided with an injection channel 311 and a sliding channel 331a respectively, and the two ends of ...

Embodiment 3

[0052] This embodiment provides a feeding device for an injection molding machine, which can be preferably used in various existing injection molding machines.

[0053] combine Figure 4 As shown, the charging device in this embodiment includes a charging device body 400 .

[0054] Wherein, the feeding device body 400 includes a feed hopper 410, the opening above the feed hopper 410 is a feeding port, and the opening below the feed hopper 410 is a discharge port; the side wall of the feed hopper 410 is provided with a plurality of screen holes 411, and The outer side of the bucket 410 is provided with a protective cover 420, and an airtight cavity is formed between the protective cover 420 and the feeding hopper 410; the inner side of the protective cover 420 is provided with a third excitation winding 430, and the inner side of the third excitation winding 430 is provided with a plastic layer 440, the plastic An independent dust collection chamber 450 is formed between the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com