Hard anodizing method of deep-hole aluminum parts and deep-hole aluminum parts made therefrom

A hard anodizing, deep-hole aluminum technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve the problems of ablation, easy breakdown of the oxide film layer, etc. Stable and controllable effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

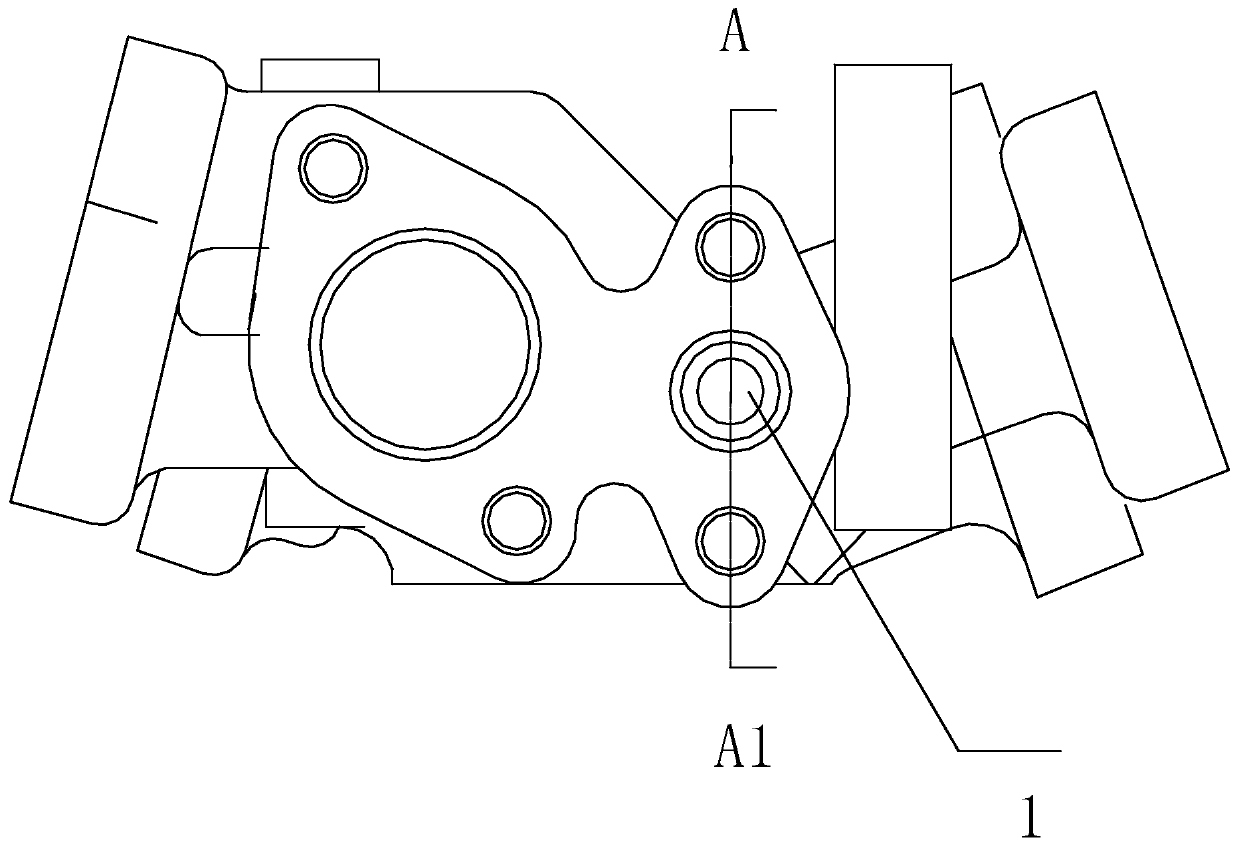

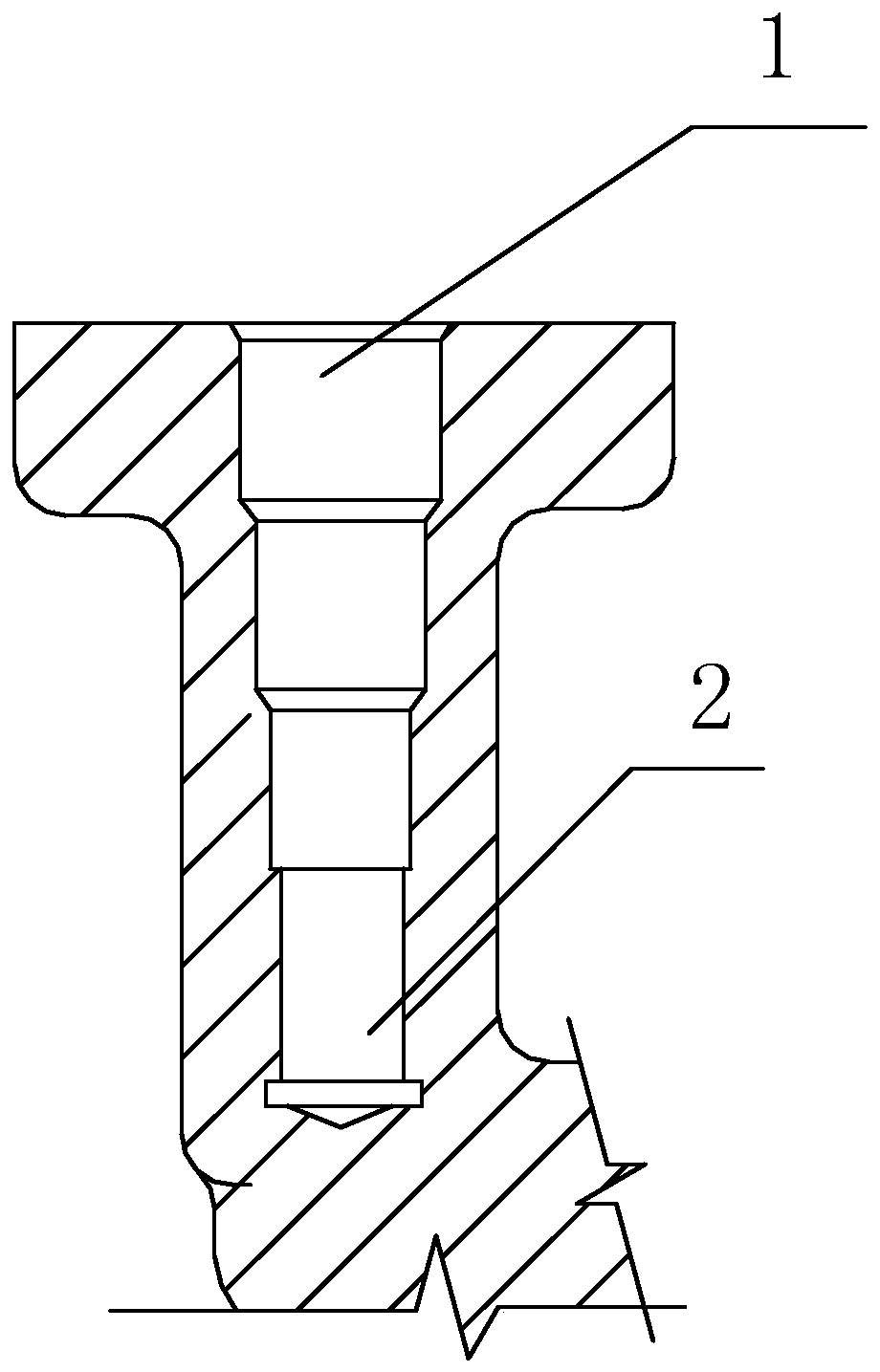

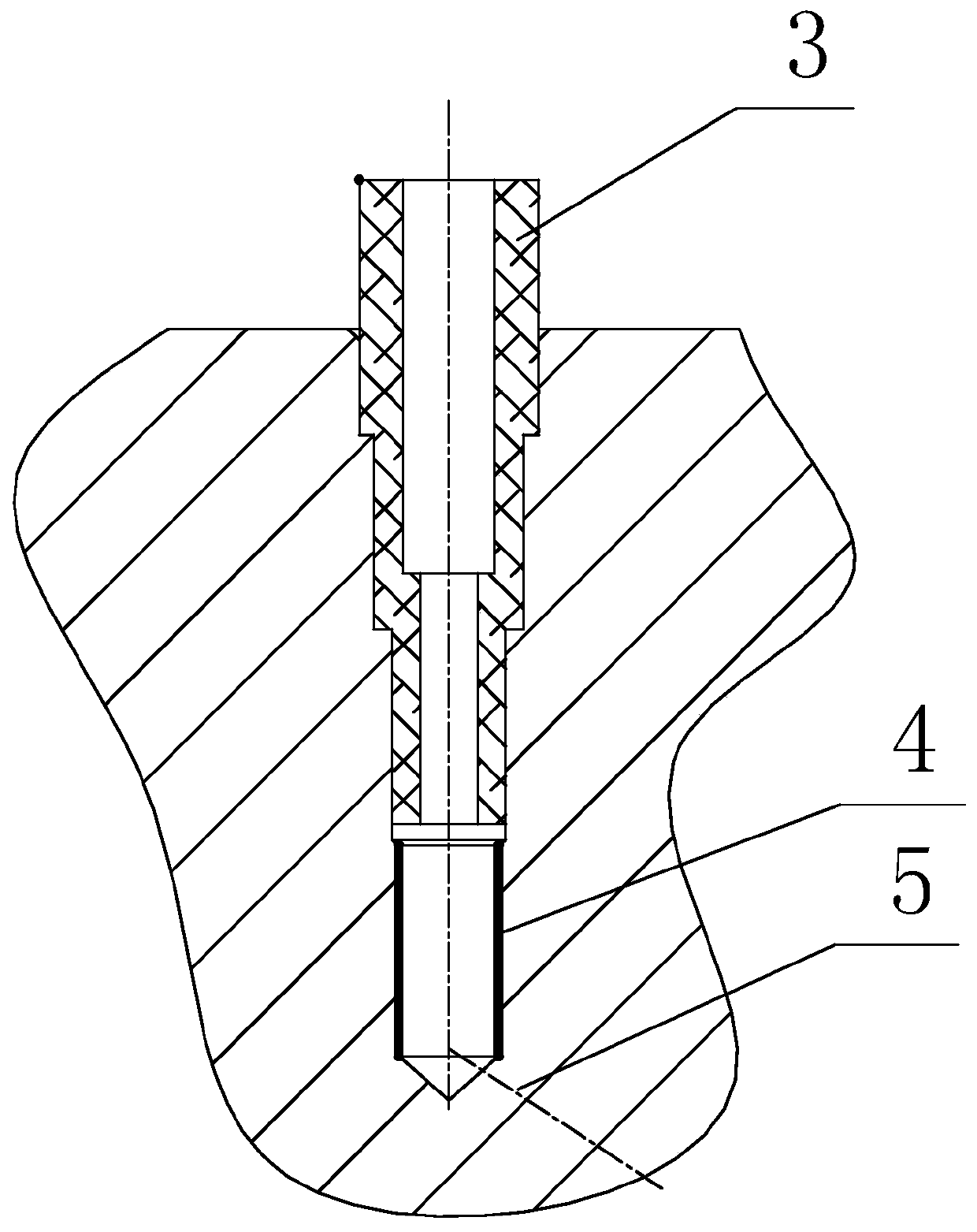

[0048] A preferred embodiment of the present invention provides a method for hard anodizing an aluminum part with a deep hole, which is used for the aluminum part with a first through hole in the part 4 to be hard anodized in the deep hole 1 . This embodiment takes the valve housing as an example, refer to figure 1 , figure 2 As shown, the valve housing is provided with a deep hole 1 of φ6.92, and the part 4 to be hard anodized is located at the bottom of the deep hole 1 of φ6.92, which is the side wall of the fourth step hole 2, and the hard anodized part 4 is located at the bottom of the deep hole 1 of φ6. The anodized part 4 includes a first through hole, that is, a φ3 small oil hole 5 at the bottom of the deep hole 1, and the φ3 small oil hole 5 communicates with the outside of the valve housing. In this embodiment, the hard anodizing method for the side wall of the fourth step hole 2 of the valve housing includes the following steps:

[0049] (a) Insert the clamp 3 mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com