Quick release system for marine flexible vertical riser

A technology of flexible riser and piping system, which is applied in the direction of drilling pipe, casing, drilling equipment, etc., and can solve problems such as inability to evacuate urgently, high engineering risk, secondary disasters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

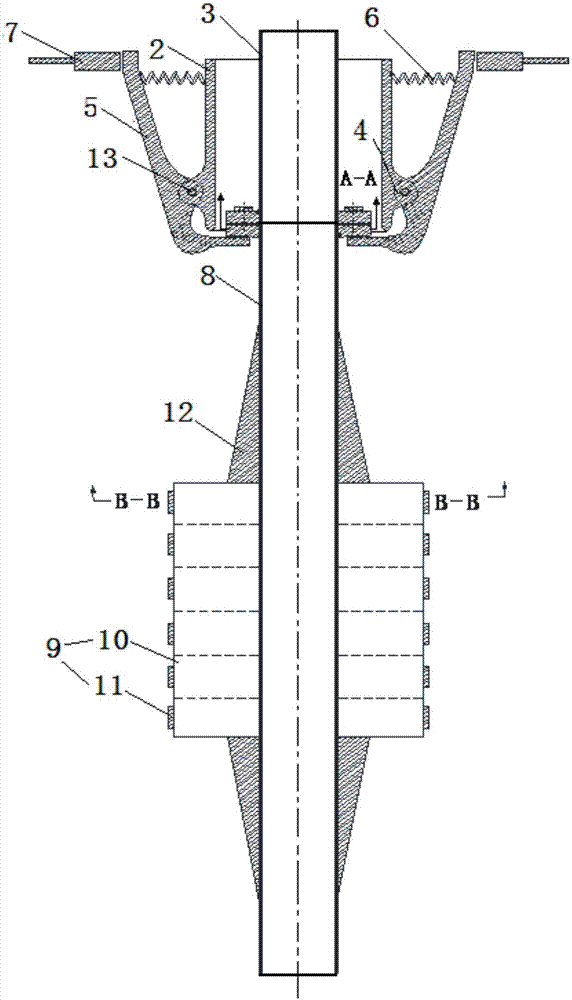

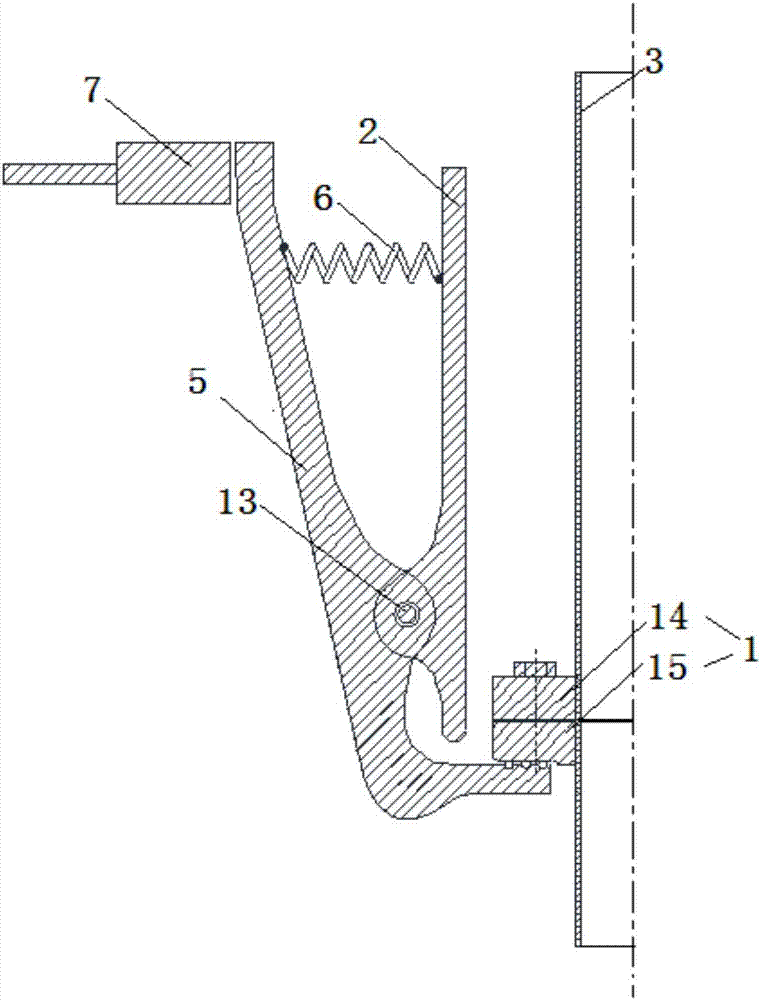

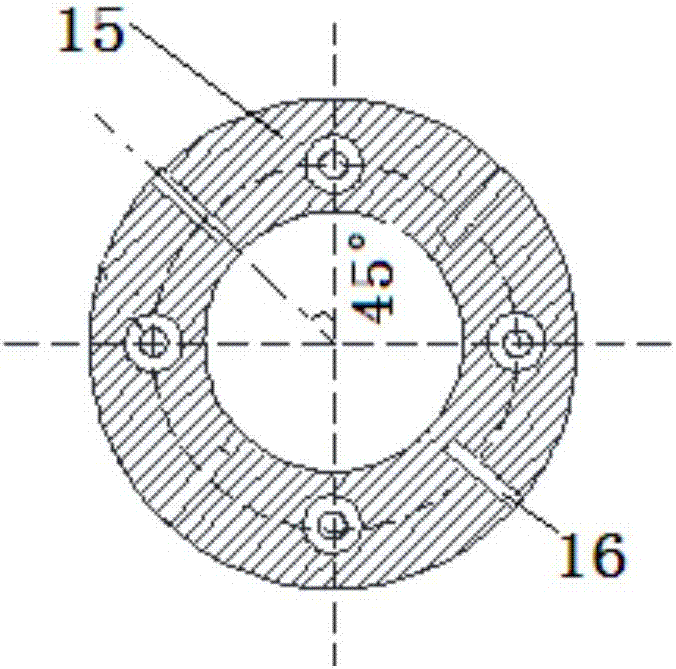

[0021] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a piping system and a riser system connected to the lower end of the piping system through an annular riser joint 1. The piping system includes a piping 3 and a tubular riser suspension structure that is concentrically arranged with the piping 3 and fixed to the hull. 2. The standpipe joint 1 is arranged at the bottom of the pipe 3, and a plurality of reinforcing ribs 4 are evenly spaced on the outer wall of the standpipe suspension structure 2, and an L-shaped claw lock is rotatably connected to each reinforcing rib 4 Tightening mechanism 5, the upper end of the claw locking mechanism 5 is connected with the side wall of the standpipe suspension structure 2 through the compression spring 6, so that the upper end of the claw locking mechanism 5 maintains an outwardly expandin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com