Large-section tunnel support removing and replacing and secondary lining construction method

A construction method and large-section technology, applied in tunnel linings, tunnels, shaft linings, etc., can solve problems such as unfavorable waterproofing and quality assurance of concrete construction, multiple construction sections in one-time dismantling of braces, and increasing the setting of tunnel construction joints, etc. Improve the conversion efficiency and stability, simplify the construction process content, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

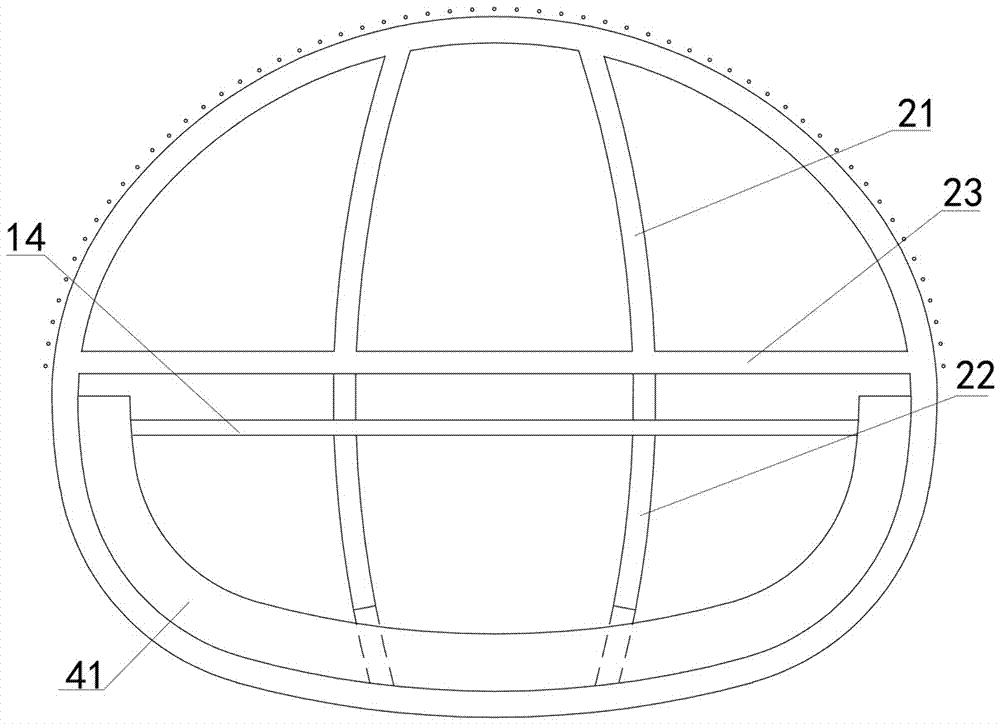

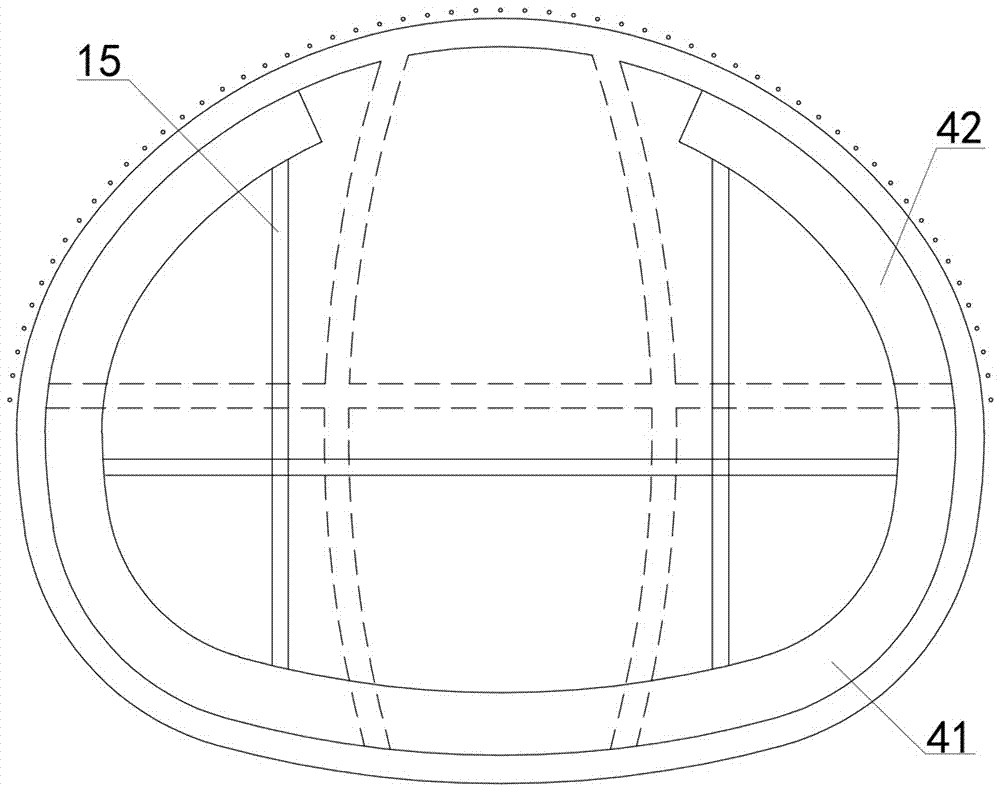

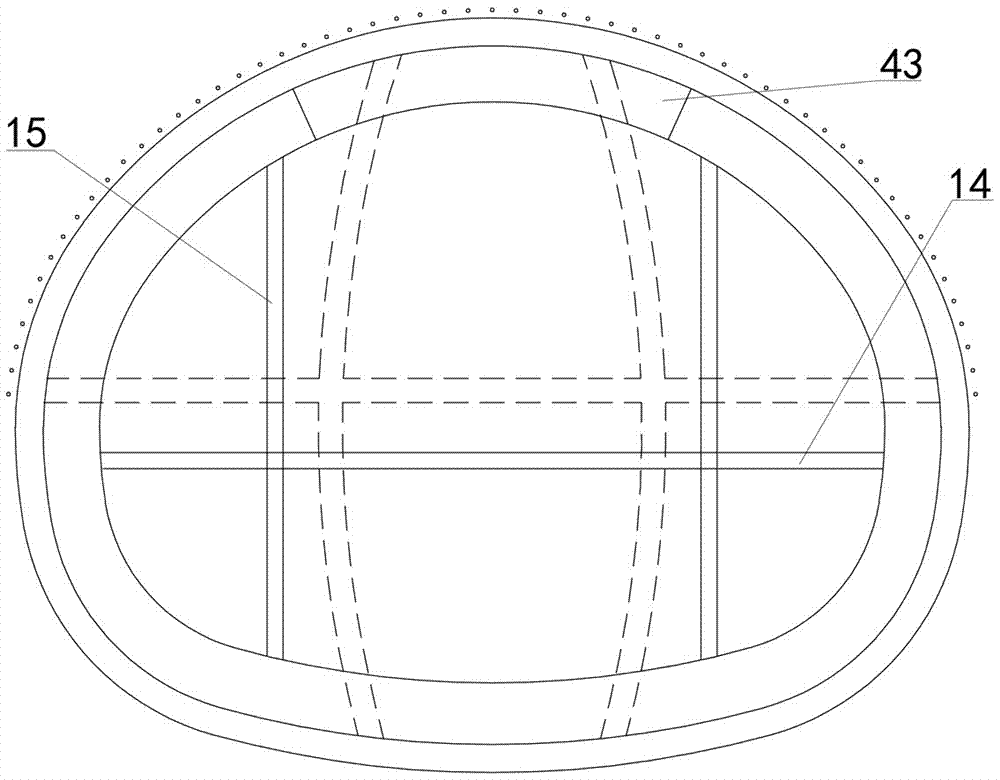

[0080] Examples see Figure 5-13 As shown, the existing structure of a large-section tunnel structure includes an initial lining structure 1 and an initial lining temporary structure 2 .

[0081] The primary lining structure 1 includes a primary lining invert 11, a primary lining side wall 12 and a primary lining top arch 13, and the primary lining temporary structure 2 is a steel arch frame, including being arranged in the primary lining structure and separating large-section tunnels into The middle partition and temporary inverted arch of the cavern. The middle partition is divided into the upper middle partition 21 and the lower middle partition 22 according to the location of the cavern. The temporary inverted arch is divided into the side wall between the middle partition and the primary lining side wall. Temporary inverts 23 at the part and temporary inverts 24 in the middle between the partition walls.

[0082] The structure to be constructed of the large-section tunne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com