Centrifugal water pump provided with two impellers

A centrifugal, double-impeller technology, applied in the field of water pumps, can solve problems such as increasing structural complexity, reducing bearing life, and reducing incoming water potential energy, and achieves the effects of facilitating external connections, increasing lift, and increasing flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

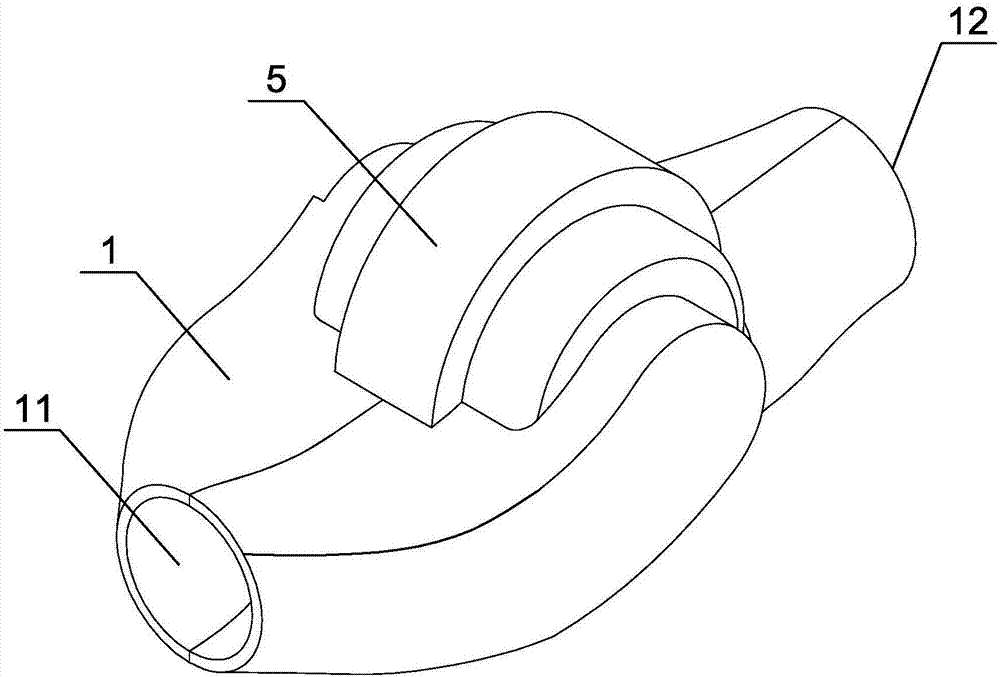

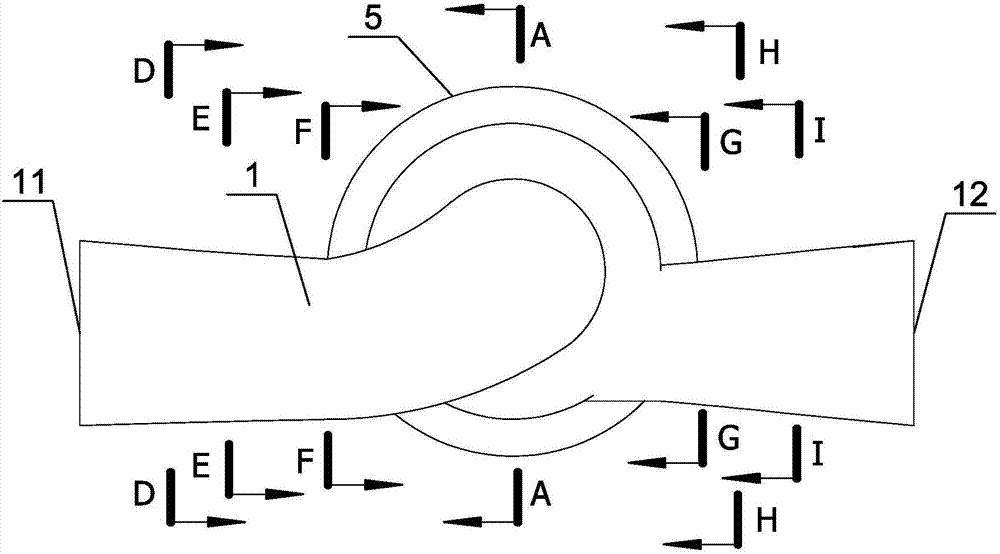

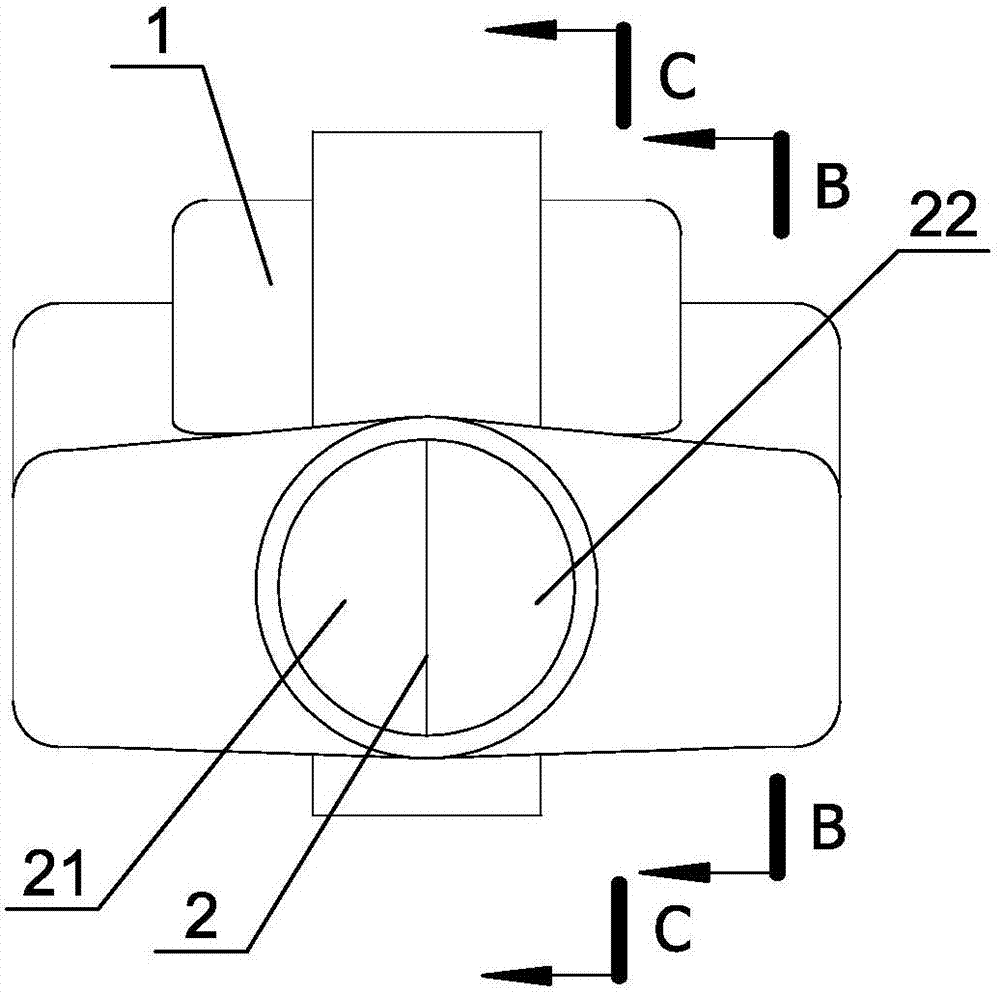

[0034] like Figure 1 to Figure 16As shown, the double-impeller centrifugal water pump in this embodiment includes a pump body 1, a water inlet 11 and a water outlet 12 are respectively provided at both ends of the pump body 1, and a water inlet 11 is provided in the pump body 1. There is a water inlet partition 2, which divides the water inlet channel into a first water inlet channel 21 and a second water inlet channel 22, and the pump body 1 is provided with a water outlet partition 3 at the water outlet 12, which divides the water outlet channel into the first water outlet flow 31 and the second water outlet channel 32, the pump body 1 is provided with a motor assembly, the motor assembly includes a main shaft 8, a stator 5 with coils, the two ends of the main shaft 8 are respectively connected to the first impeller 41, the second Two impellers 42, the stator 5 is located in the center of the pump body 1, the middle hole of the stator 5 is provided with a rotor base 61 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com