Special built-in valve for worm type gas meter

A gas meter and worm technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of complex transmission structure, large movement occupied volume, high parts manufacturing cost and assembly cost, and reduce the valve size. The effect of reducing volume, reducing the number of parts, and shortening the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

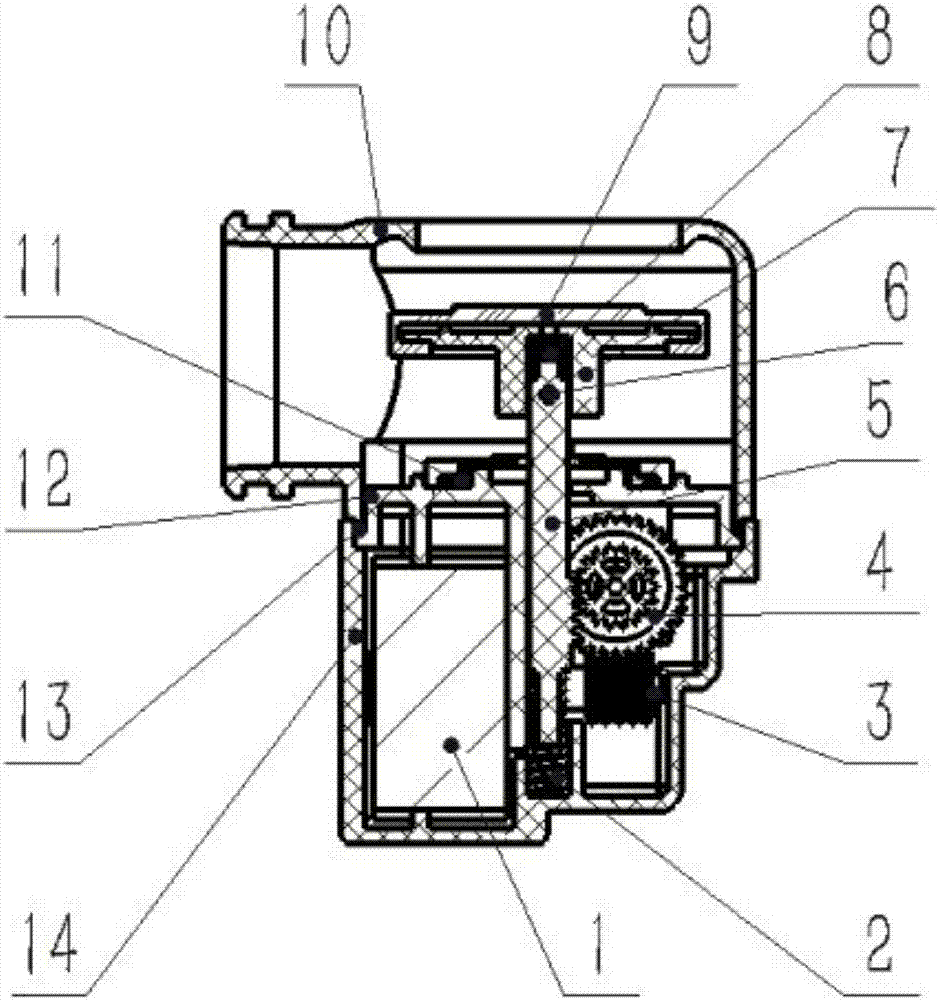

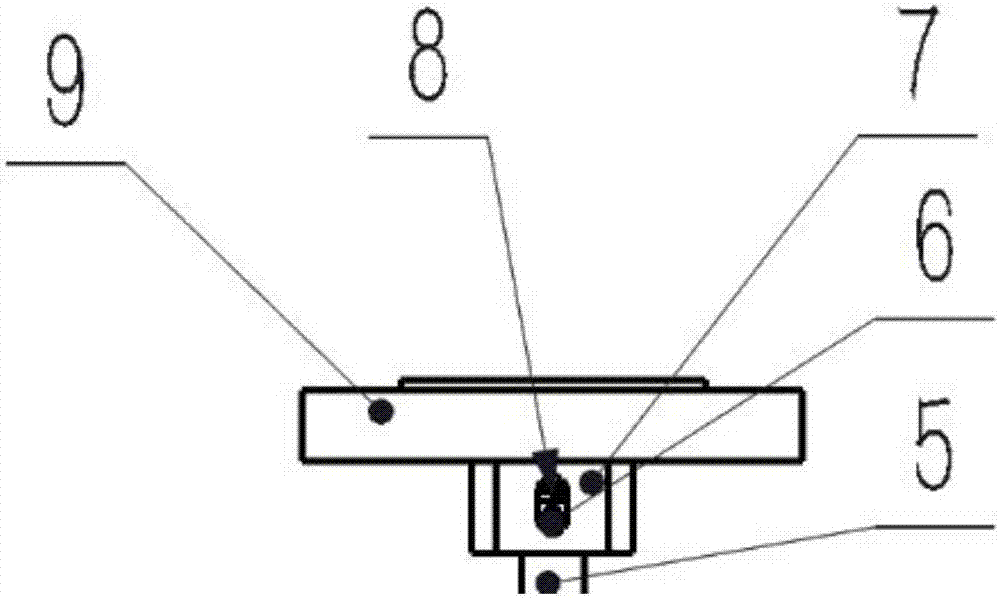

[0020] Such as figure 1 and figure 2 As shown, a special built-in valve for a worm screw type 3 gas meter of the present invention includes a valve seat 10, a sealing frame 7, a sealing plug 9, a core support 12, a micro-motor 1, a rack valve stem 5, a gear set 4, an upper pressure Spring 8, lower compression spring 2 and stop pin 6, valve seat 10 are divided into valve cavity and motor cavity by horizontally arranged on movement support 12, micro-motor 1 is fixedly arranged on movement support 12, the top and side of valve cavity An air outlet and an air inlet are provided respectively. The sealing plug 9 is set on the sealing skeleton 7 and is located below the air outlet. The upper end of the bar valve rod 5 passes through the positioning hole of the core support 12, the gear set 4 in the motor cavity of the rack valve rod 5 engages with the teeth of the gear set 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com