Two-dimensional embedded structure catalyst, as well as preparation method and application thereof

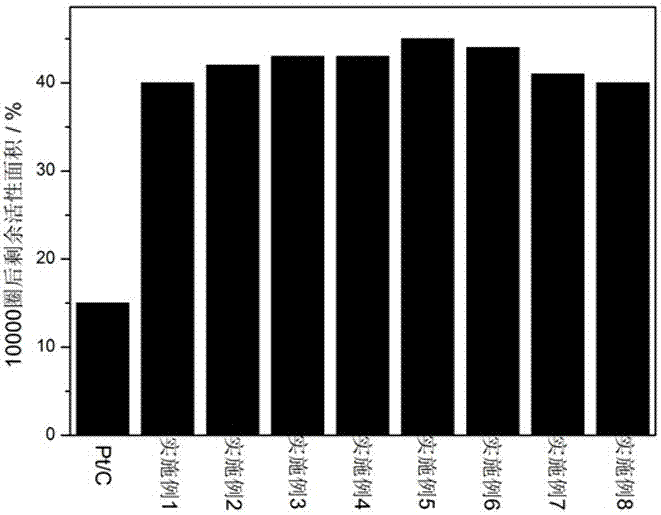

A catalyst and layer structure technology, applied in structural parts, electrochemical generators, fuel cells, etc., can solve the problems of poor catalyst durability and high cost of proton exchange membrane fuel cells, etc., and achieve the goal of improving life and good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

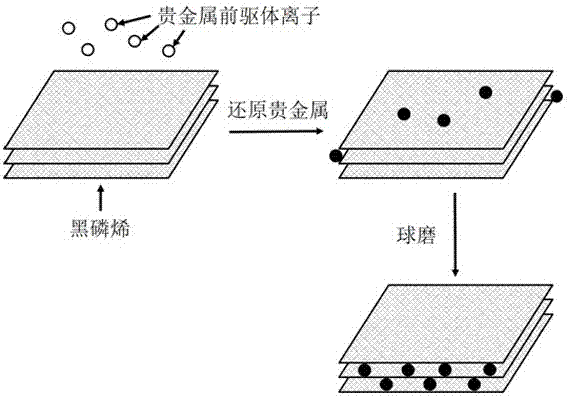

[0022] 1) Disperse 1 g of black phosphorene (the number of layers of black phosphorene used is 2 layers) and 0.05 g of noble metal precursor chloroplatinic acid in 10 mL of water, and stir thoroughly for 30 minutes to make the dispersion uniform;

[0023] 2) Add 100 mL of 0.5 mol / L sodium borohydride aqueous solution to the dispersion obtained in step 2), and stir thoroughly for 30 minutes;

[0024] 3) Filtration, and the obtained product was heated and dried at 100°C for 60 hours under the protection of nitrogen;

[0025] 4) The product obtained in step 3) was ball milled for 10 hours under the protection of nitrogen to obtain a highly durable two-dimensional embedded structure catalyst in which platinum metal was embedded between black phosphorene layers.

Embodiment 2

[0027] 1) Disperse 1 g of black phosphorene (the number of layers of black phosphorene used is 50 layers) and 10 g of noble metal precursor chloroplatinic acid in 100 mL of ethanol, and fully stir for 180 minutes to make the dispersion uniform;

[0028] 2) Add 10 mL of 10 mol / L sodium borohydride aqueous solution to the dispersion obtained in step 2), and stir thoroughly for 180 minutes;

[0029] 3) Filtration, and the obtained product was heated and dried at 180 °C for 6 hours under the protection of argon;

[0030] 4) The product obtained in step 3) was ball milled for 100 hours under the protection of argon to obtain a highly durable two-dimensional embedded structure catalyst in which platinum metal was embedded between black phosphorene layers.

Embodiment 3

[0032] 1) Disperse 1 g of black phosphorene (the number of layers of black phosphorene used is 25) and 5 g of noble metal precursor ruthenium chloride in 55 mL of propanol, and stir thoroughly for 80 minutes to disperse evenly;

[0033] 2) Add 55 mL of 5 mol / L sodium borohydride aqueous solution to the dispersion obtained in step 2), and stir thoroughly for 80 minutes;

[0034] 3) Filtration, and the obtained product was heated and dried at 140 °C for 30 hours under the protection of helium;

[0035] 4) The product obtained in step 3) was ball milled for 60 hours under the protection of helium to obtain a highly durable two-dimensional embedded structure catalyst in which ruthenium metal was embedded between black phosphorene layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com