Experimental device applied to simulating high-temperature fused salt washout environment

An experimental device and high-temperature molten salt technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of poor thermal insulation effect, slow heating rate of thermocouple, and unsatisfactory simulation effect, and achieve fast heating rate and good thermal insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

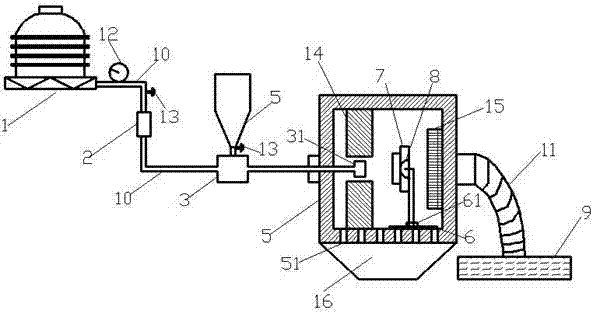

[0012] like figure 1 As shown, the present invention is used to simulate the experimental device of high-temperature molten salt erosion environment, including air compressor 1, rotameter 2, spray gun 3, material storage tank 4, sandblasting box 5, sample holder 6, electromagnetic heater 7. The angle meter 8 and the water tank 9; the air compressor 1 is connected to the rotameter 2 through the pressure-resistant hose 10, and the rotameter 2 is connected to the spray gun 3 through the pressure-resistant hose 10; the storage tank 4 is arranged above the spray gun 3, and Connected with the spray gun 3, the nozzle 31 integrally connected with the spray gun 3 is placed in the sandblasting box 5, close to the front end of the entrance of the sandblasting box 5; Inside; the sample rack 6 is fixedly installed in the middle of the sandblasting box 5, and the sample rack 6 is provided with a moving guide rail 61 to facilitate adjustment of the distance between the sample and the nozzle;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com