Infrared Spectroscopy On-line Testing Method of Lubricating Oil High Temperature Friction Process

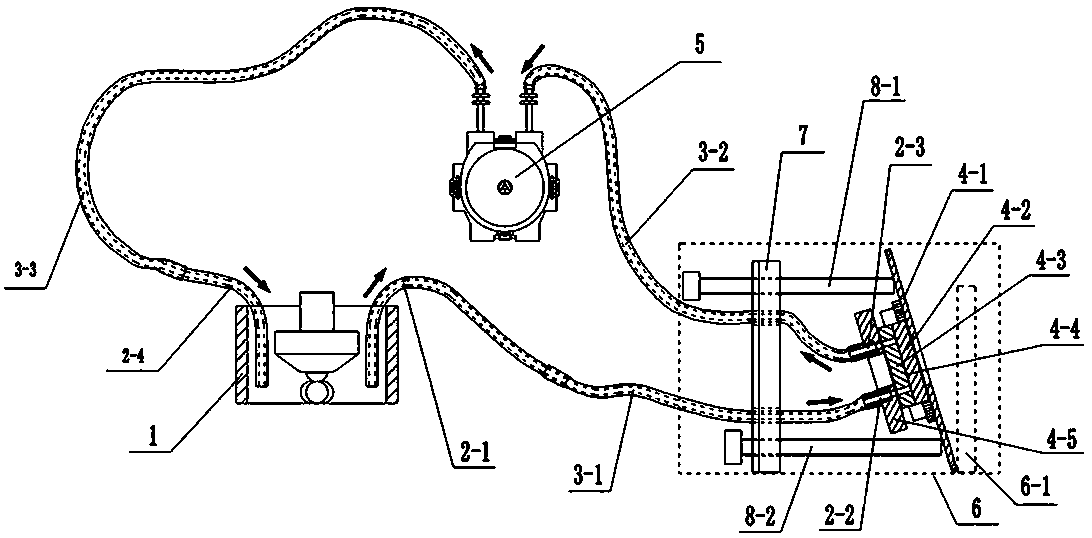

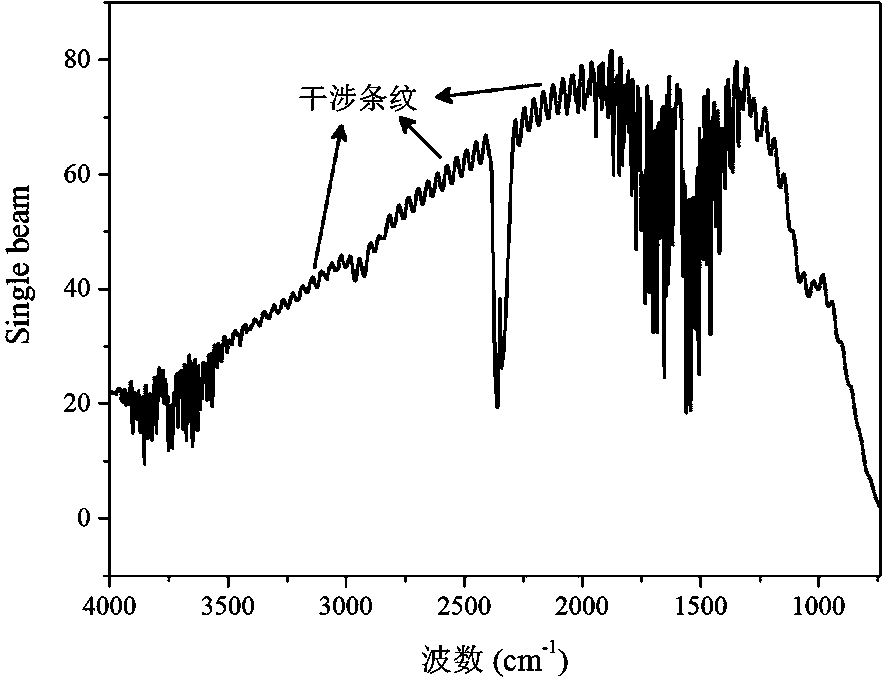

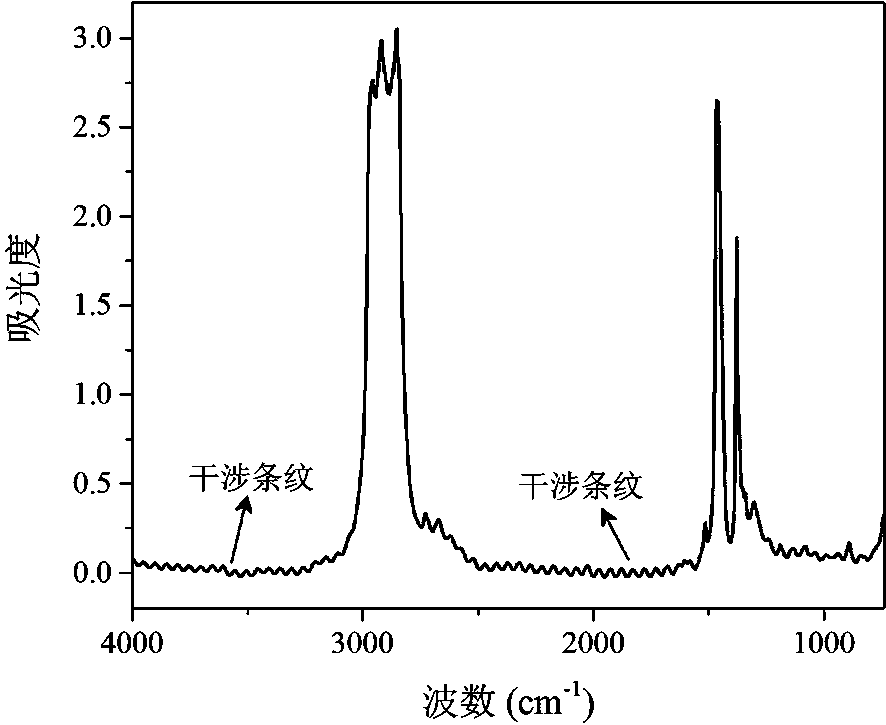

An infrared spectrum and online testing technology, which is applied in the field of infrared spectrum online testing, can solve problems such as the inability to continuously detect the structural changes of lubricating oil online, and the inability to collect online infrared spectrum dynamic data of lubricating oil, so as to achieve online infrared spectrum testing and ensure reliability. Sex, the effect of eliminating interference fringes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

[0048] 500SN+1.0wt% T558 Infrared spectrum online test during high temperature friction process:

[0049] The N-H absorption peaks of the 500SN+1.0wt%T558 oil sample under room temperature friction-free conditions and high-temperature friction conditions are shown in Figure 5. After normalization, the N-H peak intensity of the 500SN+1.0wt%T558 oil sample changes with the collection time as Image 6 As shown, the N-H peak intensity of the high-temperature friction condition is subtracted from the instrument test background of the room temperature friction-free condition, and the N-H peak intensity of the 500SN+1.0wt% T558 oil sample correction under the high-temperature friction condition is changed with the collection time ( Figure 7 ). The flow rate of the 500SN+1.0wt% T558 oil sample was measured to be 0.9mL / min, and the lag time of the oil sample was calculated to be 9.8min. After deducting the lag time, the N-H peak intensity and friction time of 500SN+1.0wt% T558 in the ...

example example 2

[0052] PAO+1.0wt% T558 Infrared spectrum online test of high temperature friction process:

[0053] The N-H absorption peaks of PAO+1.0wt%T558 oil samples under room temperature friction-free conditions and high-temperature friction conditions are shown in Figure 11. After normalization, the N-H peak intensity of PAO+1.0wt%T558 oil samples changes with the collection time as Figure 12 As shown, the N-H peak intensity of the high-temperature friction condition is subtracted from the instrument test background of the room temperature friction-free condition, and the N-H peak intensity of the PAO+1.0wt% T558 oil sample correction under the high-temperature friction condition is obtained as a function of the collection time ( Figure 13 ). The measured flow rate of PAO+1.0wt%T558 is 2.0mL / min, and the lag time of the oil sample is calculated to be 4.4min. After deducting the lag time, the relationship between the N-H peak intensity and the friction time of PAO+1.0wt%T558 is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com