Optical axis consistency calibration and split-image fixed-focus adjustment device and method for non-imaging system

A non-imaging optics and consistency technology, applied in the field of optical detection, can solve the problems such as the inability to calibrate the optical axis consistency of high-precision non-imaging optical systems, and achieve excellent optical axis consistency measurement uncertainty, improve accuracy, and reduce Effects of Temporal and Spatial Coherence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

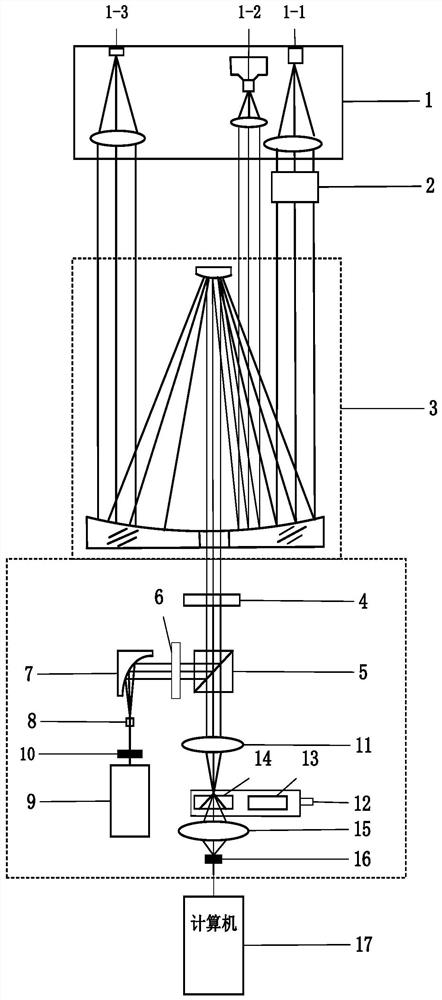

[0037] Such as figure 1 As shown, the optical axis consistency calibration and split-image fixed-focus adjustment device of the non-imaging optical system, the device consists of an attenuation system 2, a telescopic system 3, a quarter-wave plate 4, a polarization beam splitter prism (PBS) 5, Polarizer 6, off-axis total reflection optical fiber collimator 7, FC optical fiber interface 8, wide-spectrum illumination source 9, all-dielectric interference filter 10, primary imaging objective lens 11, split image insertion device 12, parallel plate 13 , a split-image focusing screen 14, a secondary imaging mirror group 15, a near-infrared detector 16 and a data processing system 17. The parallel plate 13 and the split-image focusing screen 14 are installed on the split-image drawing and inserting device 12 .

[0038] The attenuation system 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com