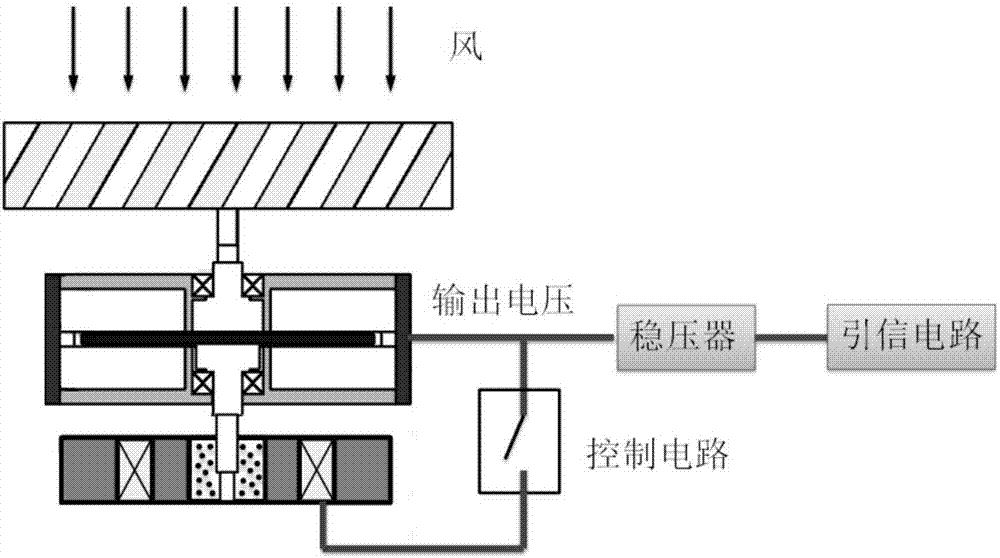

Rotating speed control device for turbogenerator based on magnetorheological material and control method

A speed control, turbine-type technology, applied in electromechanical devices, control generators, control systems, etc., can solve problems such as adverse effects of speed and damage to turbines, and achieve the effect of ensuring structural mechanics requirements, reducing density loss, and improving magnetic field strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

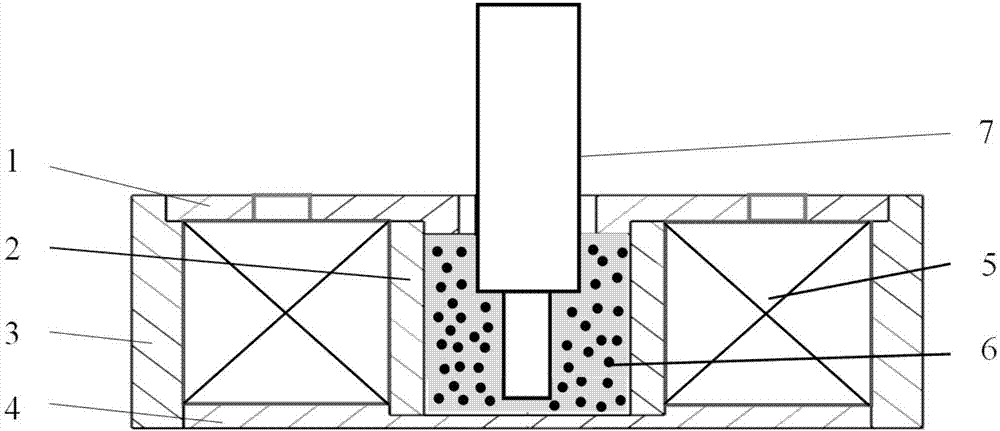

Embodiment 1

[0023]The magnetorheological material-based turbine generator speed control device disclosed in this embodiment includes an upper cover 1 , an inner cylinder 2 , a casing 3 , a bottom 4 , an excitation coil 5 and a magnetorheological material 6 . The upper cover 1, the inner cylinder 2, the outer shell 3, and the bottom 4 form a base, and the inner cylinder 2, the outer shell 3, and the bottom 4 are processed separately or integrally. The materials of the upper cover 1, the shell 3, and the bottom 4 are all metal magnetically conductive materials, which have the following two advantages: 1. It is beneficial for the magnetic force lines to pass through the magnetorheological material 6 in the working chamber more concentratedly, forming a closed magnetic force line , so as to reduce the density loss of the magnetic lines of force and increase the magnetic field strength in the magnetorheological material 6; 2. It can ensure the structural mechanical requirements of the speed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com