Middle bundle core

A beam core and fork technology, applied to the types of packaging items, applications, special packaging items, etc., can solve the problems of complex shrapnel structure, irreversible deformation, etc., and achieve the effect of not being easily irreversible deformation, low manufacturing cost, and easy mold opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

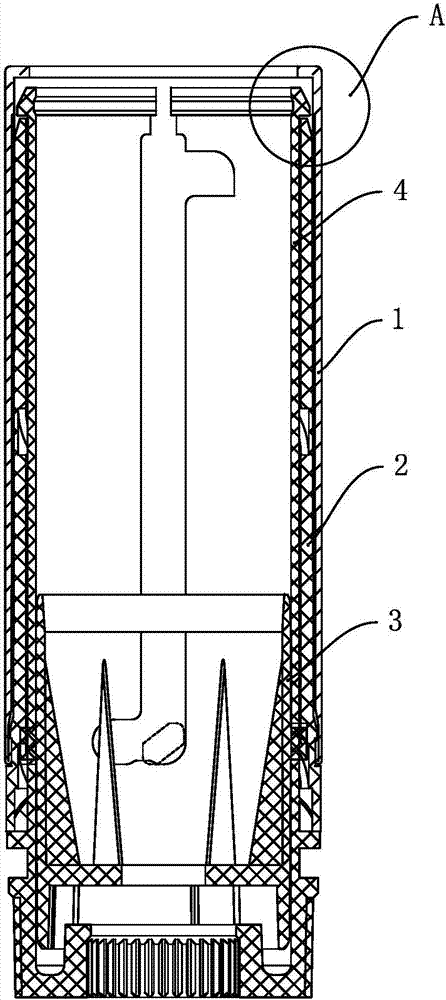

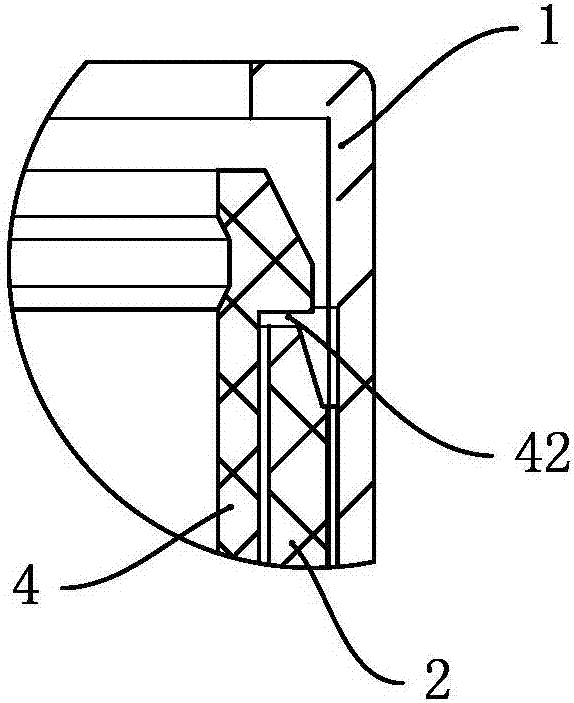

[0030] like figure 1 As shown, an existing middle beam core includes a middle beam 1, a spiral 2, a fork 4 and a bead 3, which are coaxially threaded together from the outside to the inside in sequence, and the outer wall of the fork is provided with two convex rings, forming two The limit step, which cooperates with the two ends of the screw 2, limits its axial movement. like figure 2 As shown, there is a gap of about 0.1 mm between the top end of the screw 2 and the limit step 42 due to the machining error.

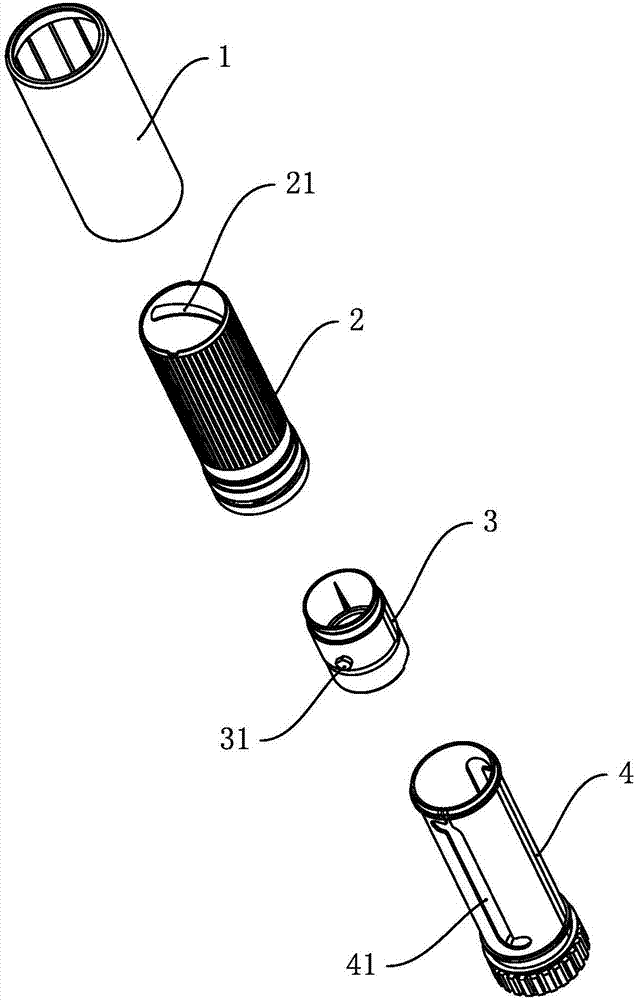

[0031] like image 3 and 5 As shown, the beam core in the present invention is also composed of a middle beam 1, a helix 2, a fork 4 and a bead 3. The inner wall of the helix 2 has a helical groove 21, and the fork 4 is provided with a guide groove 41 arranged along its axial direction. The outer wall of the bead 3 is provided with two protrusions 31 extending into the groove 21 through the guide groove 41 , and the middle beam 1 is fixedly sleeved on the outer per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com