Chip breaking device of adjustable circular ultra-hard turning tool

An adjustable and chip-breaking technology, which is applied to the accessories of tool holders, tools for lathes, turning equipment, etc., can solve the problems of frequent shutdown, difficult processing, high processing cost, etc., and achieve reliable and stable clamping and chip breaking Good effect, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

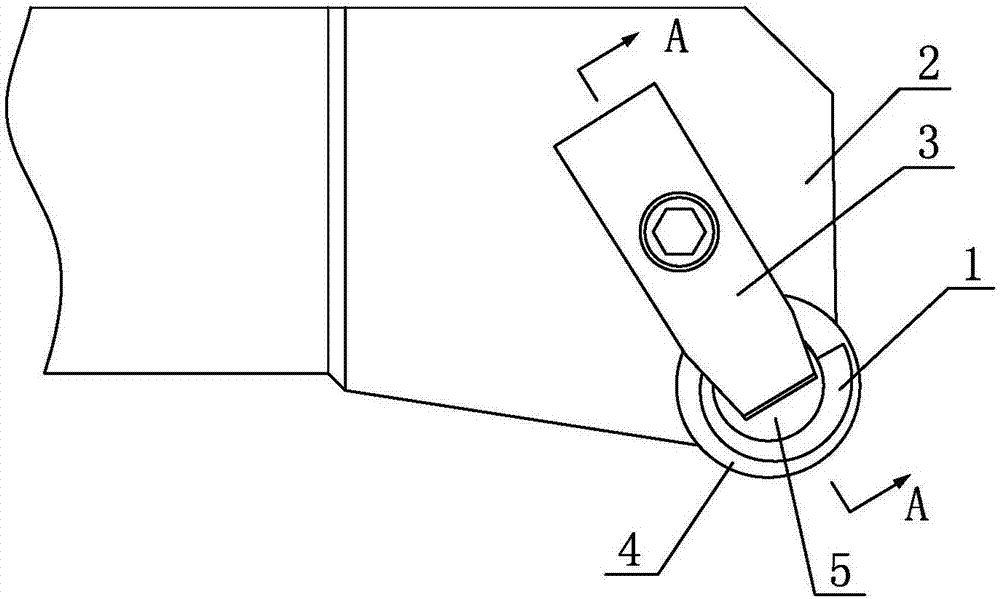

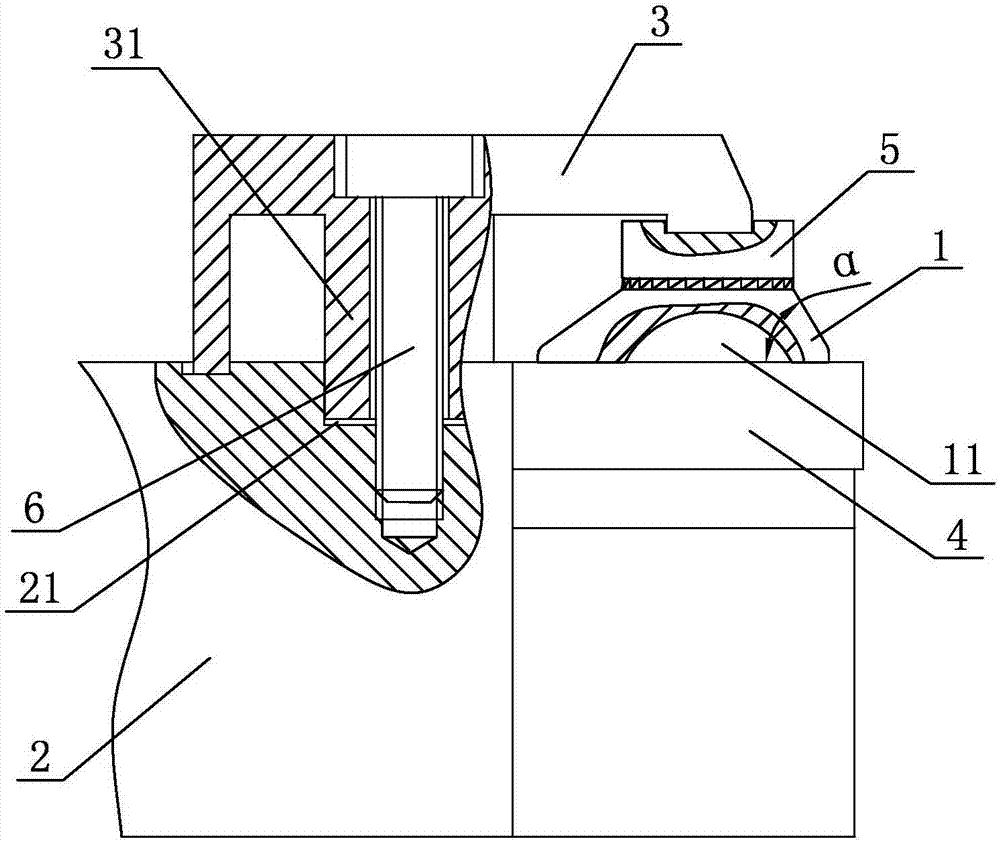

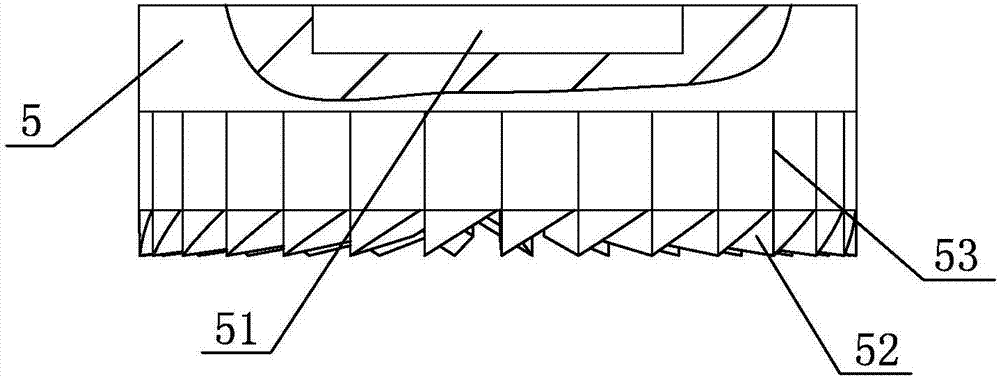

[0018] As shown in the figure, a chip breaking device for an adjustable round superhard turning tool includes a chip breaking block 1 and a blade pressure plate 3 fixedly installed on the handle 2, and the chip breaking block 1 is located On the upper end surface, the peripheral surface of the chip breaking block 1 is in a spiral shape, and its helix is an Archimedes spiral, a hyperbolic spiral or a Fibonacci spiral, and the lower end surface of the chip breaking block 1 is provided with a concave cavity 11 , A chip-breaking block angle adjustment mechanism is arranged between the blade pressure plate 3 and the chip-breaking block 1, the chip-breaking block angle adjusting mechanism includes an auxiliary block 5, the auxiliary block 5 is arranged above the chip-breaking block 1, and the upper end surface of the auxiliary block 5 is set There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com