Polishing device for aluminum alloy tank truck panel

A liquid tanker and aluminum alloy technology, which is applied to machine tools, grinders, grinding racks and other directions suitable for grinding the edge of workpieces, can solve problems such as poor fusion of welds, reduced service life of plates, and long consumption time. , to achieve excellent grinding effect, improve production efficiency, and reduce labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

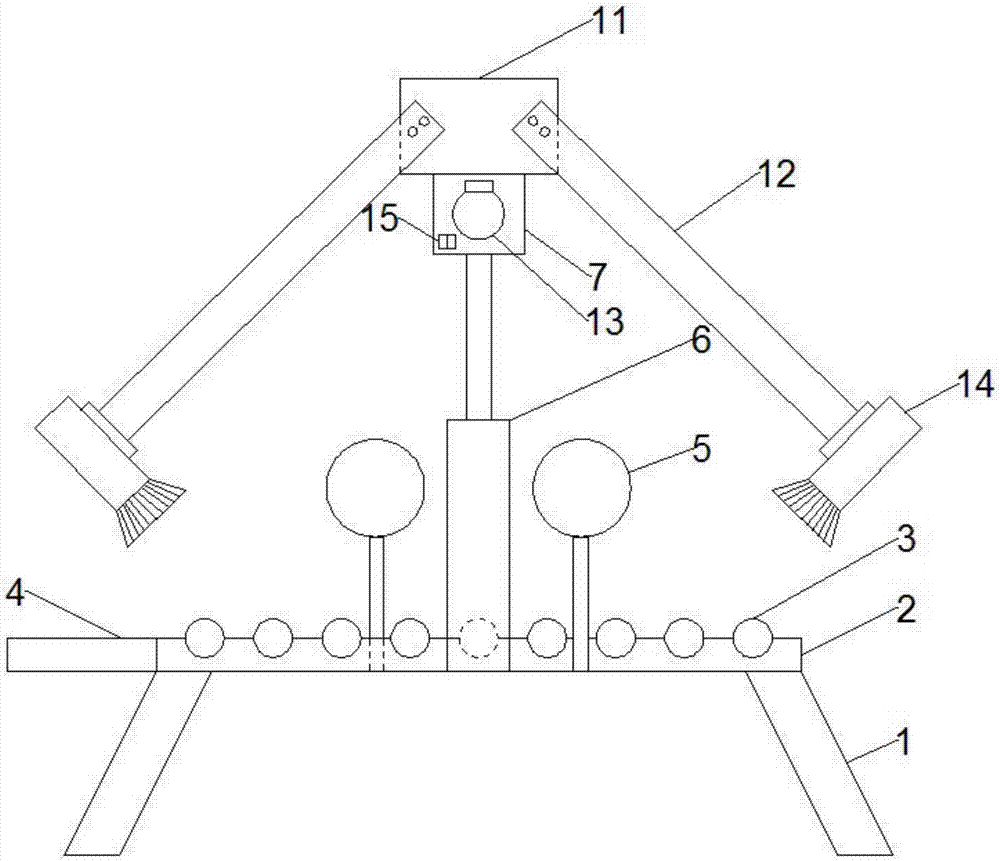

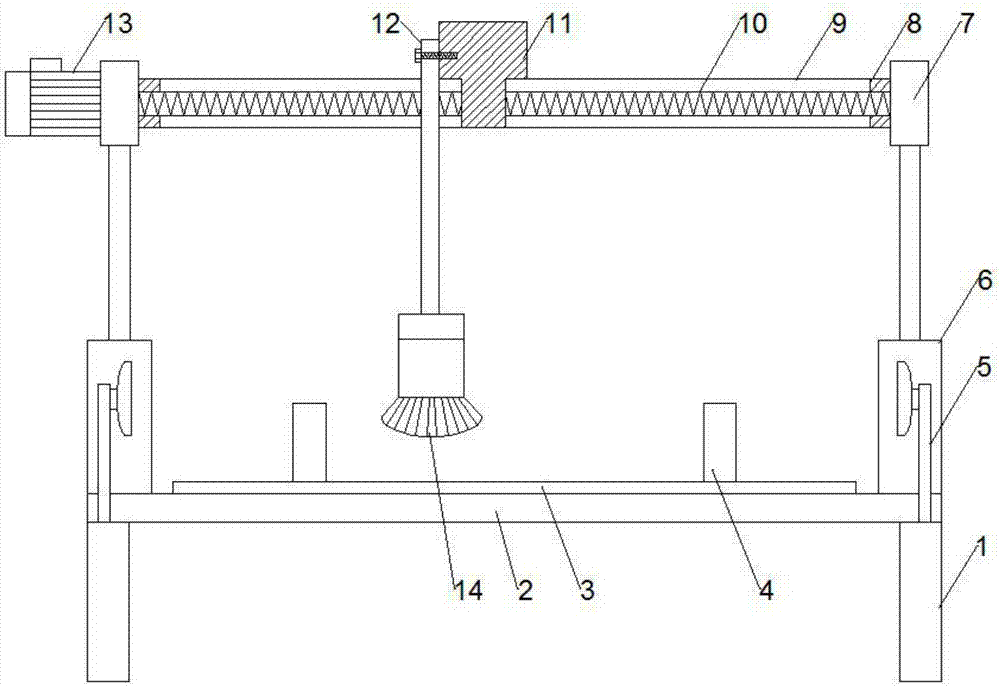

[0014] figure 1 with figure 2 The specific embodiment of the present invention is shown: a grinding device for aluminum alloy liquid tank truck plates, including a support platform 2, the bottom of the support platform 2 is provided with a leg 1, and a plurality of rollers 3 are provided in the support platform 2 One side of the support platform 2 is hinged with a limit plate 4, and the two ends of the support platform 2 are provided with a lifting device 6, and the lifting device 6 is provided with a mounting plate 7, and a slide is provided between the mounting plates 7. rail 9, the slide rail 9 is provided with a screw 10, the mounting plate 7 is provided with a motor 13 and a start switch 15 electrically connected to it, the screw 10 is connected to the main shaft of the motor 13, the wire The rod 10 is provided with a threaded sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com