Tire blank three-dimensional truss robot automatic conveying line

A three-dimensional truss and automatic conveying technology, which is applied to tires, household appliances, and other household appliances, can solve the problems of high physical labor intensity, low production efficiency, and easy pollution of embryos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

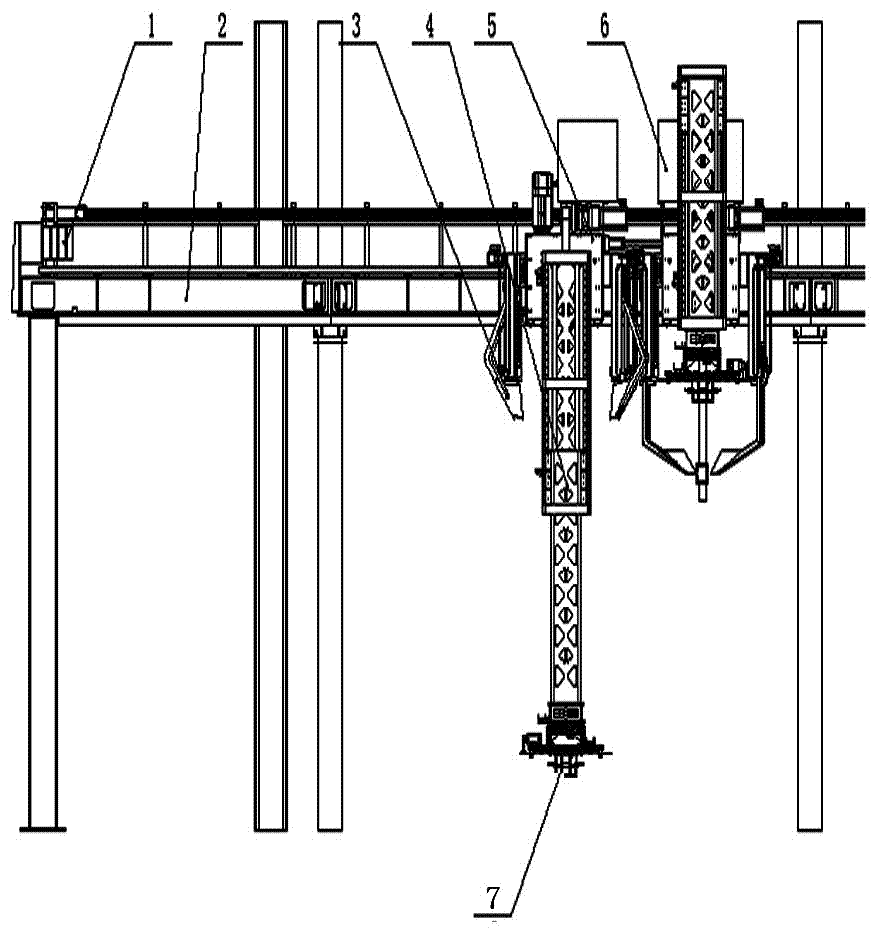

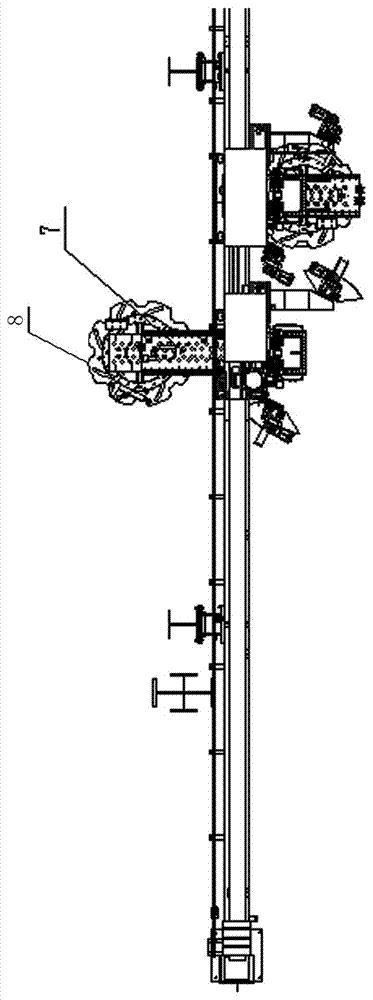

[0019] The tire blank three-dimensional truss robot automatic conveying device of the present invention comprises a walking guide rail 2, a walking device 5, a lifting hydraulic device 4, a tire gripping manipulator and an electric control box 6, and the walking device 5 includes a slider and a fixed connection thereto. stand. The walking guide rail 2 is erected horizontally in the air, the bracket is arranged parallel to the walking guide rail 2, and is connected with the walking guide rail 2 through a slider, and the lifting hydraulic device 4 is arranged vertically to the walking guide rail 2. The lifting hydraulic device 4 includes a movable truss, a fixed truss and a lifting hydraulic cylinder, the movable truss is sleeved inside the fixed truss, and is movably connected to the fixed truss through the lifting hydraulic cylinder. The tire gripping manipulator comprises a motor, a rotary chuck 8, a fixed plate, an electric cylinder and several tire claws 7, and the rotary c...

Embodiment 2

[0024] This embodiment is basically the same as Embodiment 1, except that a sliding guide rail is symmetrically arranged on both sides of the fixed truss in this embodiment, and a second sliding rail is respectively provided between one end of the two sliding guide rails and the fixed truss. block, one end of the two sliding guide rails is respectively retractable on the second slider, and the two sliding guide rails are movably connected with the fixed truss through the second slider; The tire claws 7 are arranged between the two tire protection baffles 3, and the projections of the two tire protection baffles 3 on the horizontal plane are arc-shaped. The centers of circles surrounded by projections on the same horizontal plane coincide; expansion and contraction hydraulic cylinders are respectively arranged between the two sliding guide rails and their corresponding second sliders.

[0025] Present embodiment is provided with two tire protection baffles 3 on the outside of g...

Embodiment 3

[0027] This embodiment is basically the same as Embodiment 1 or Embodiment 2, the difference is that the other ends of several tire gripping claws 7 described in this embodiment away from the claws are respectively rolled up, and this structure can make the tire gripping claws 7 grasp When picking up the embryo, hook up the inner wall of the embryo to achieve a reliable grasping action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com