Railway tunnel automatic deicing device and method

A tunnel and automatic technology, applied in the direction of overhead installation, cable installation, electrical components, etc., can solve the problems of workers' life safety hazards, economic losses, invasion, etc., to reduce manual inspections and ice, save labor costs, and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

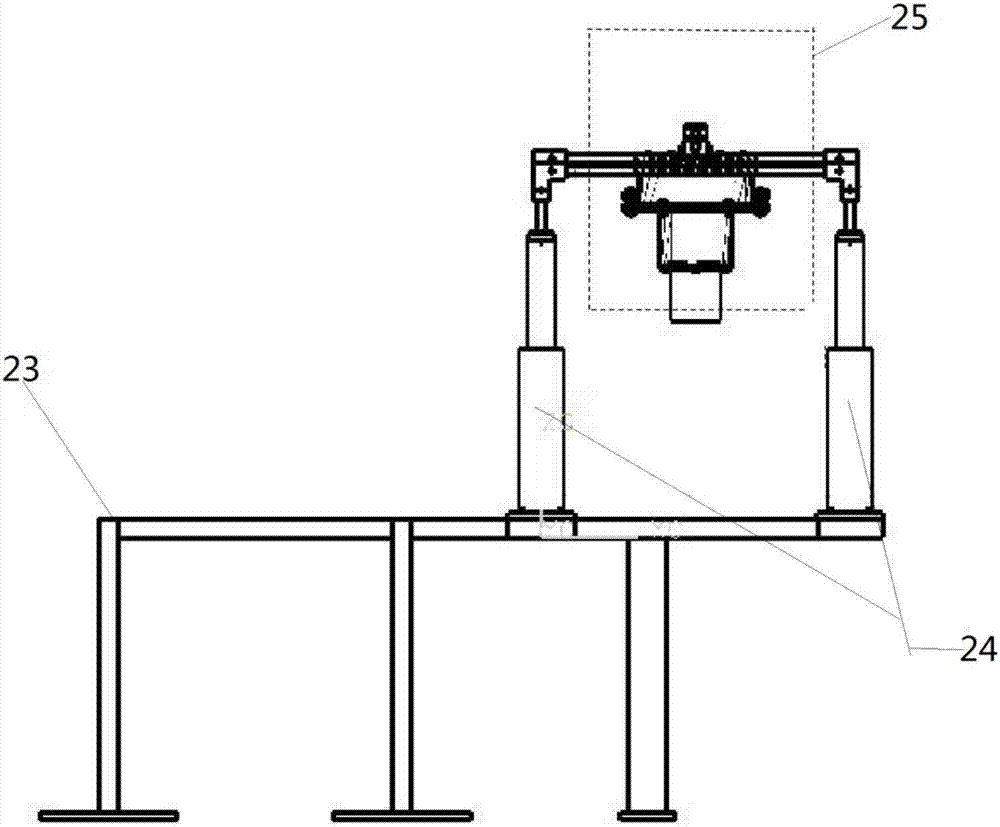

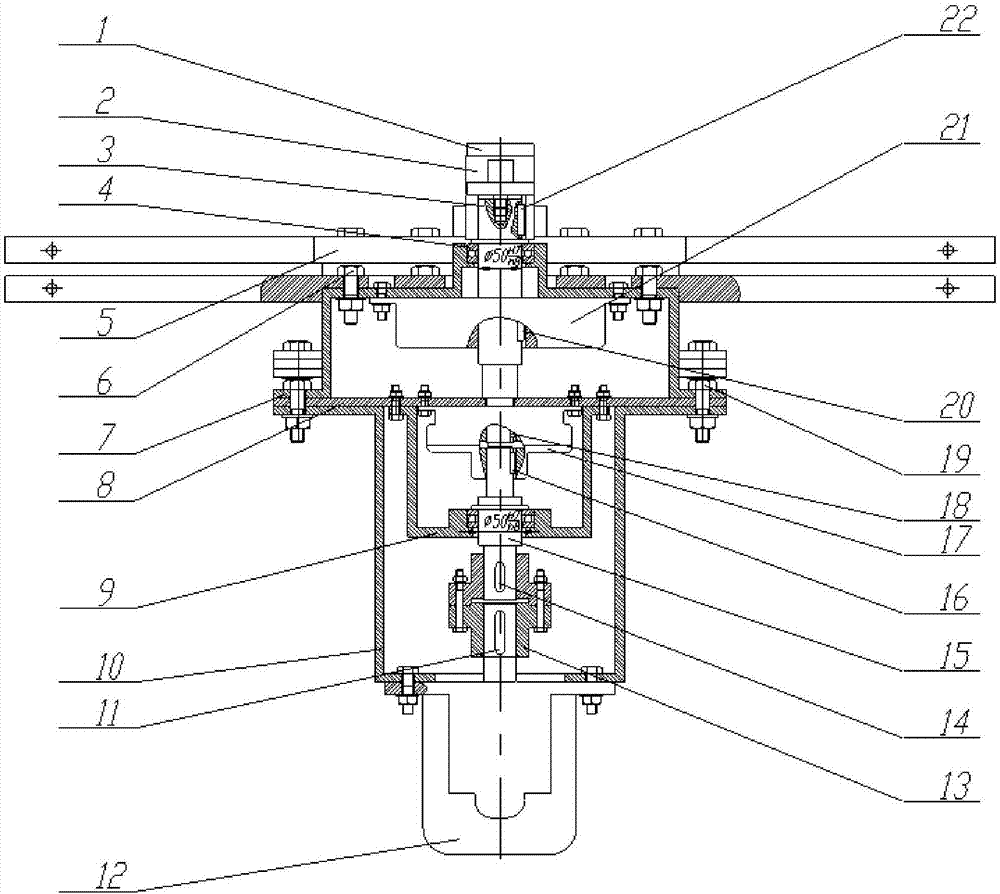

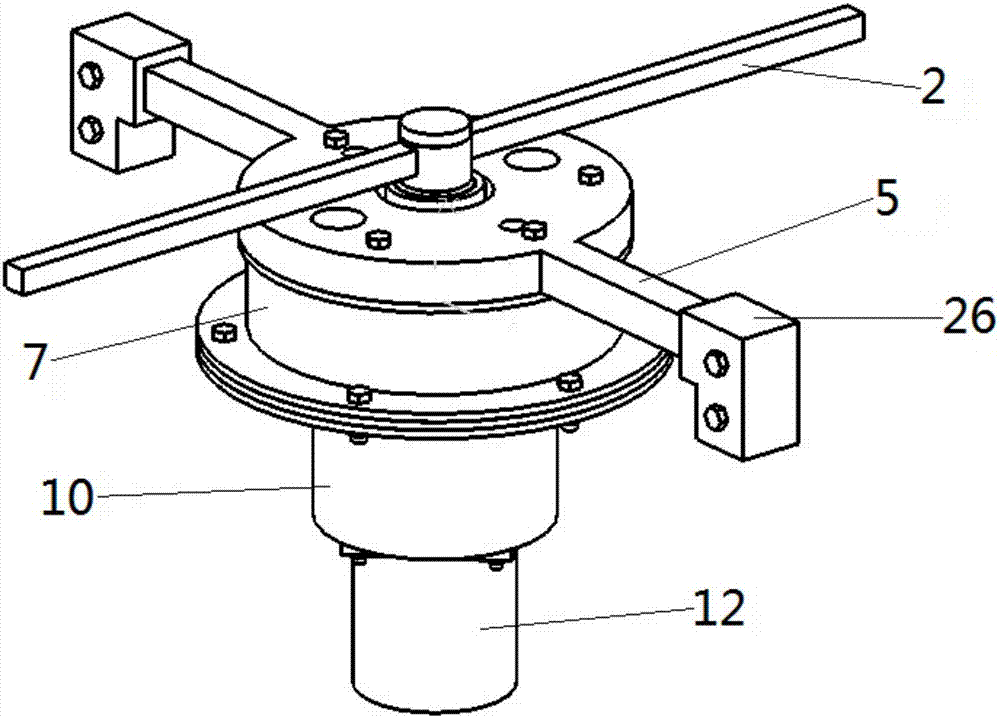

[0026] figure 2 Show this railway tunnel automatic deicing device, be used to be installed on the platform of the base support assembly 23 of train roof front end, be installed with two groups of synchronous hydraulic cylinders 24 in vertical direction, the left and right sides of the suspension frame 5 in horizontal direction The ends are correspondingly fixed on the tops of the two piston rods of the two groups of synchronous hydraulic cylinders 24; the deicing action mechanism 25 is fixed on the suspension frame, and the deicing action mechanism 25 is: the shaft of the servo motor 12 in the vertical direction passes through the shaft coupling The device 13 is connected with the No. 2 shaft 15, the No. 2 shaft 15 is used as the transmission main shaft and connected with the driving end of the electromagnetic clutch 17, the lower end of the No. 1 shaft 3 is connected with the driven end of the electromagnetic clutch 17, and the middle part of the deicing rod 2 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com