Cashmere opening and loosing mechanism

A loose, cashmere technology, used in fiber cleaning machines, cleaning with suction devices, textiles and papermaking, etc., can solve the problems of increasing the number of mixing, long time required, poor mixing effect, etc. Increase the effect, improve the efficiency, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

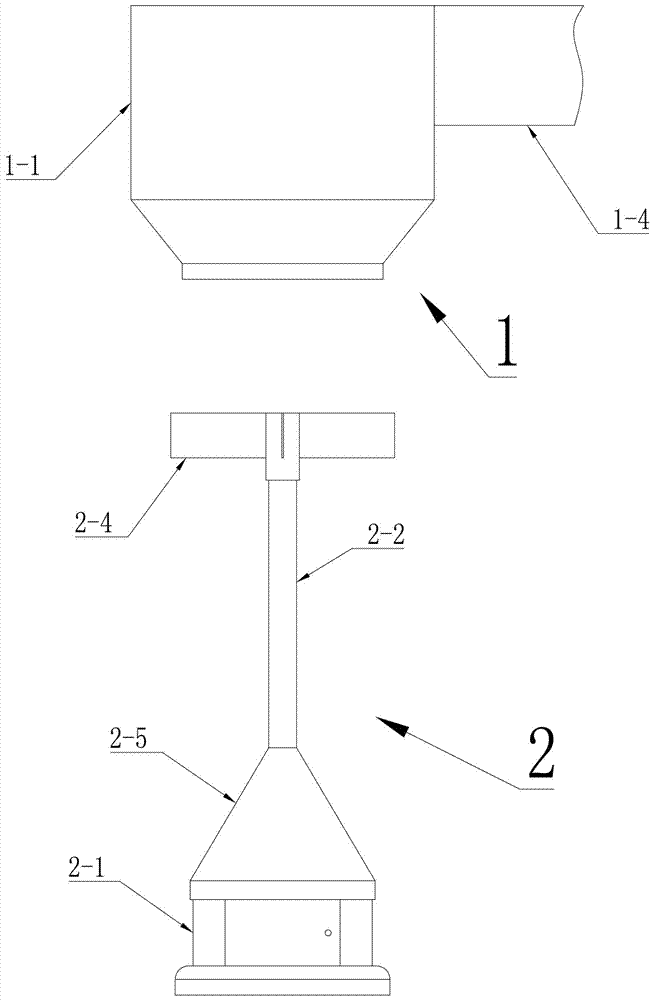

[0030] Such as figure 1 As shown, a cashmere opening and loosening mechanism includes a discharge opening device 1 and a wool loosening device 2 arranged directly below it.

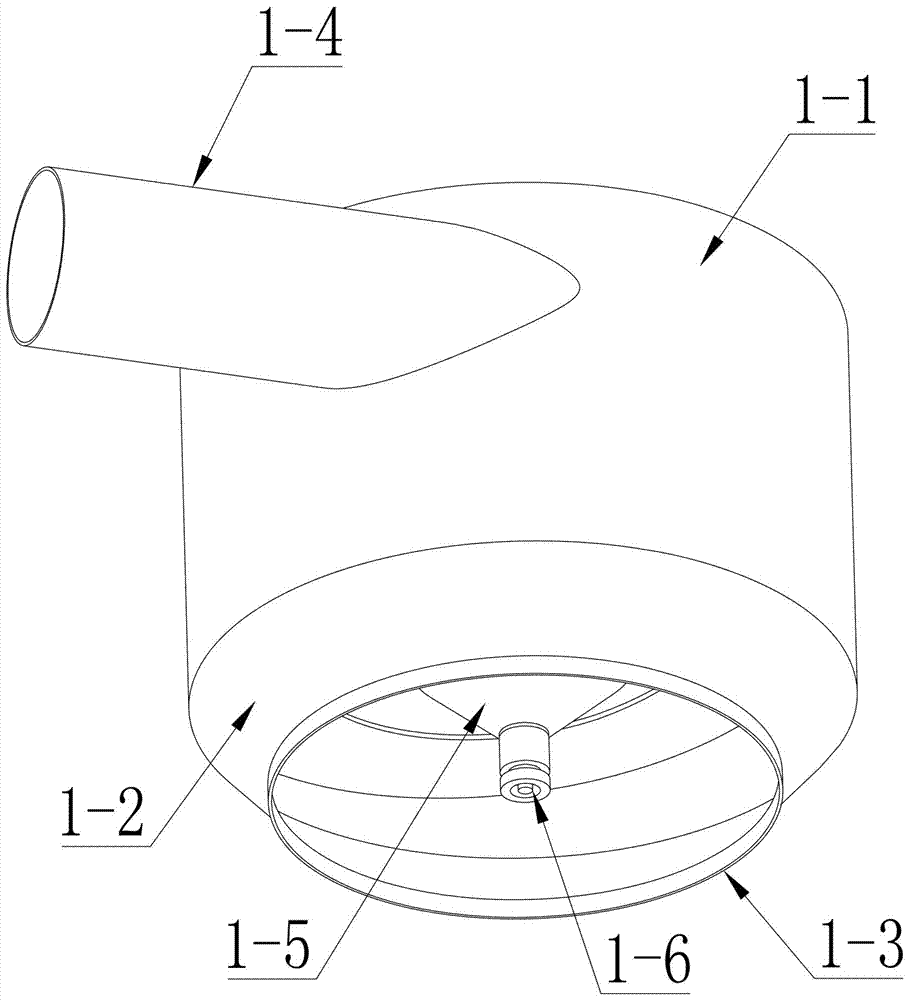

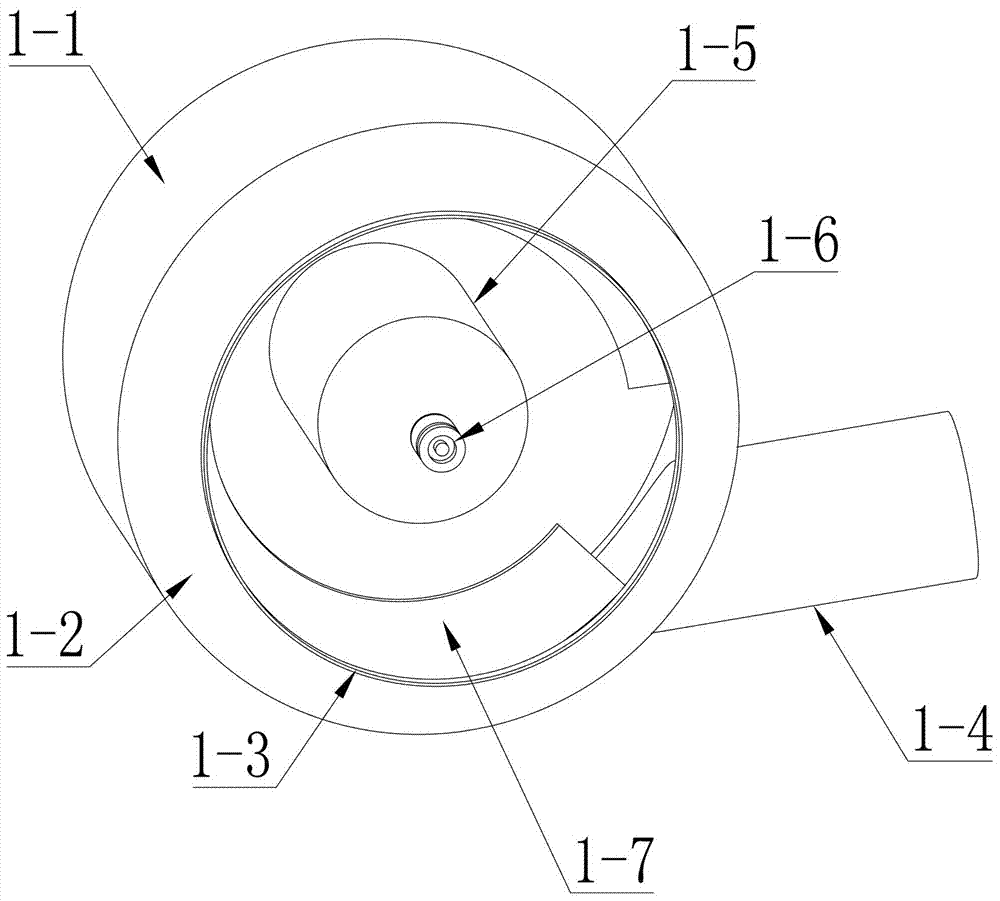

[0031] Such as Figure 2-7 The shown outlet device 1 comprises a circular straight cylindrical shell 1-1 and a feed pipe 1-4 connected thereto. The top of the shell 1-1 is closed and the bottom is open. Barrel 1-4 is arranged on the side wall of shell 1-1 and near its top, as Figure 4 As shown, the outer side of the feeding pipe 1-4 is tangent to the housing 1, and the cashmere that has been loosened enters into the housing 1-1 from the tangential direction, so that it is pressed by the circular side wall of the housing 1-1. The restriction forms a vortex-like airfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com