Terrace pavement system for ecological glow stones

A floor and ecological technology, applied in the field of floor paving system, can solve the problems of wasting manpower, material and financial resources, reducing the service life of buildings, rotten roots of upper ground plants, etc., to beautify the environment, long service life, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

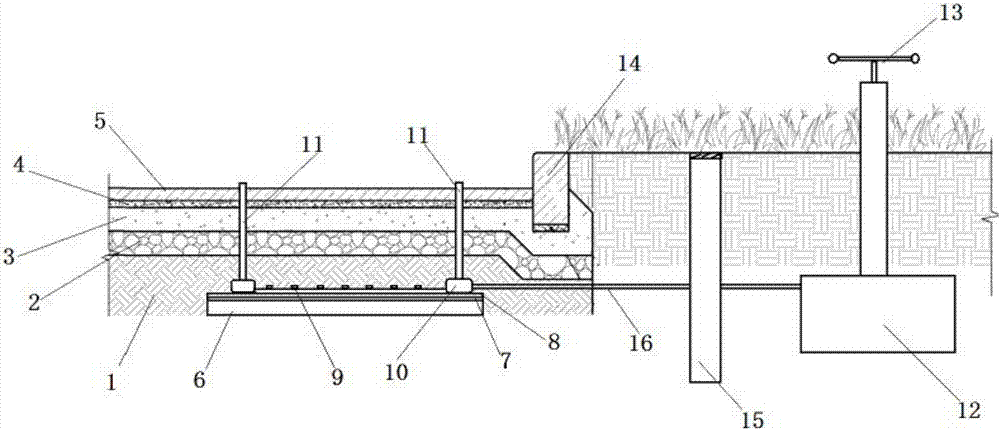

[0028] like figure 1 As shown, a floor pavement system for ecological luminous stones, the system includes a plain soil compacted layer 1, a crushed stone cushion 2, a plain concrete cushion 3, Cement mortar bonding layer 4 and luminescent stone pavement layer 5, an underground building 6 is set in the plain soil tamping layer 1, and an insulation layer 7 and a waterproof layer 8 are arranged on the top of the underground building 6, and a siphon drainage unit is arranged on the waterproof layer 8 .

[0029] Wherein, the siphon drainage unit includes a drainage plate 9 and a siphon drainage groove 10 arranged on the waterproof layer 8 and connected to each other, a siphon pipe 11 whose top extends to the floor surface and communicates the siphon drainage groove 10 with the outside world, and a drainage pipe 16 and The rainwater collecting tank 12 that is connected with the siphon drainage tank 10, the liquid level gauge that is arranged in the rainwater collecting tank 12, th...

Embodiment 2

[0034] In this embodiment, the thickness of the luminous stone pavement layer 5 is 80 mm, and the surface fluctuation of the luminous stone pavement layer 5 is not greater than 3 mm. The cement-mortar bonding layer 4 has a thickness of 40mm, the plain concrete cushion 3 has a thickness of 120mm, and the gravel cushion 2 has a thickness of 110mm.

[0035] All the other are with embodiment 1.

Embodiment 3

[0037] In this embodiment, the thickness of the luminous stone pavement layer 5 is 60 mm, and the surface fluctuation of the luminous stone pavement layer 5 is not greater than 3 mm. The cement-mortar bonding layer 4 has a thickness of 35mm, the plain concrete cushion 3 has a thickness of 90mm, and the gravel cushion 2 has a thickness of 105mm.

[0038] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com