Automatic frame assembling device for solar heat collector

A technology for solar collectors and power devices, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of high cost, low quality stability, poor efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below through specific examples.

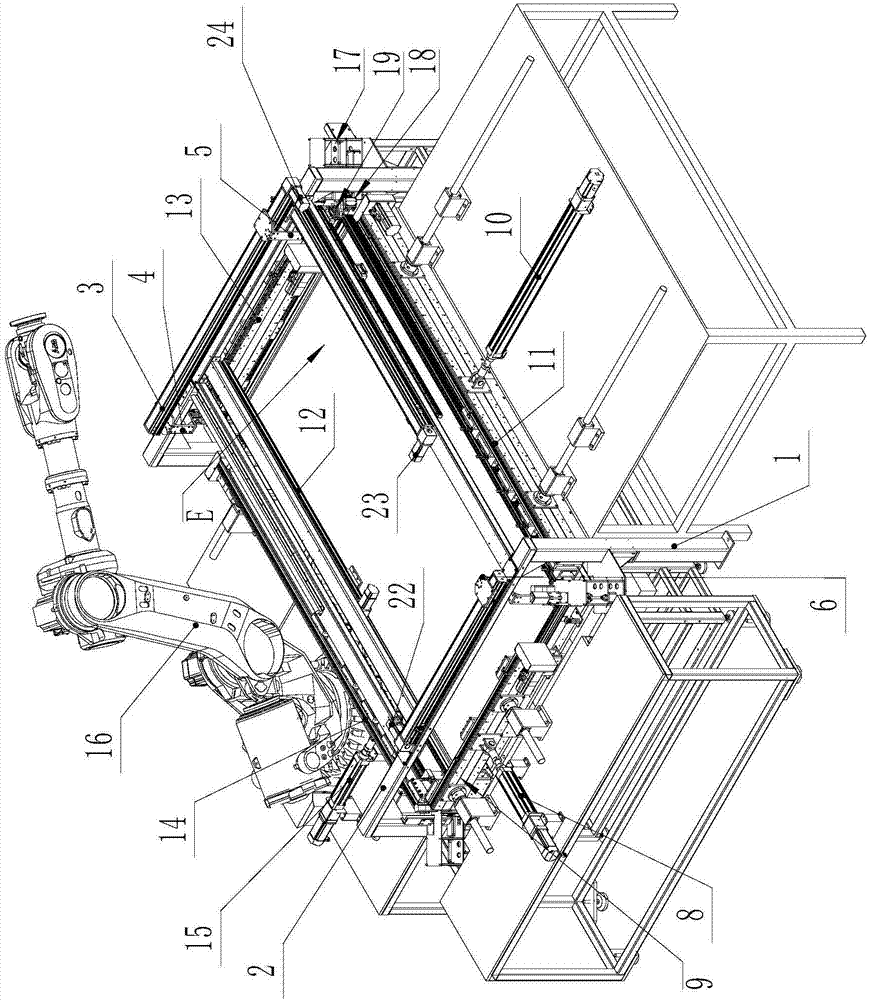

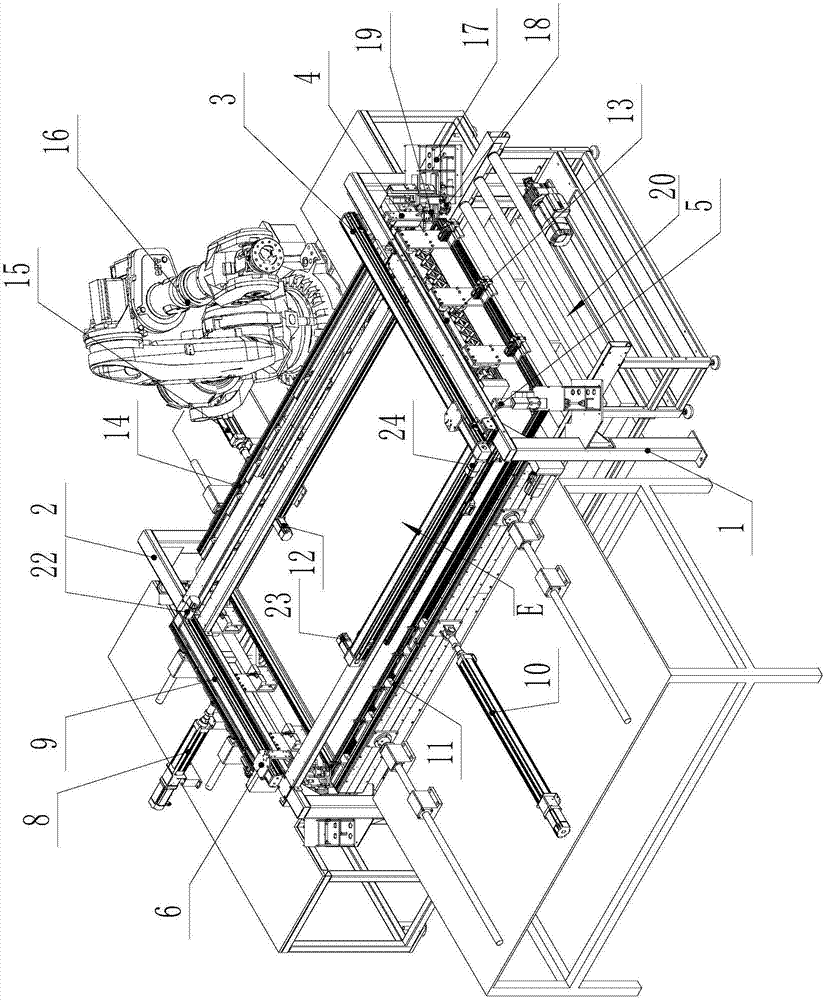

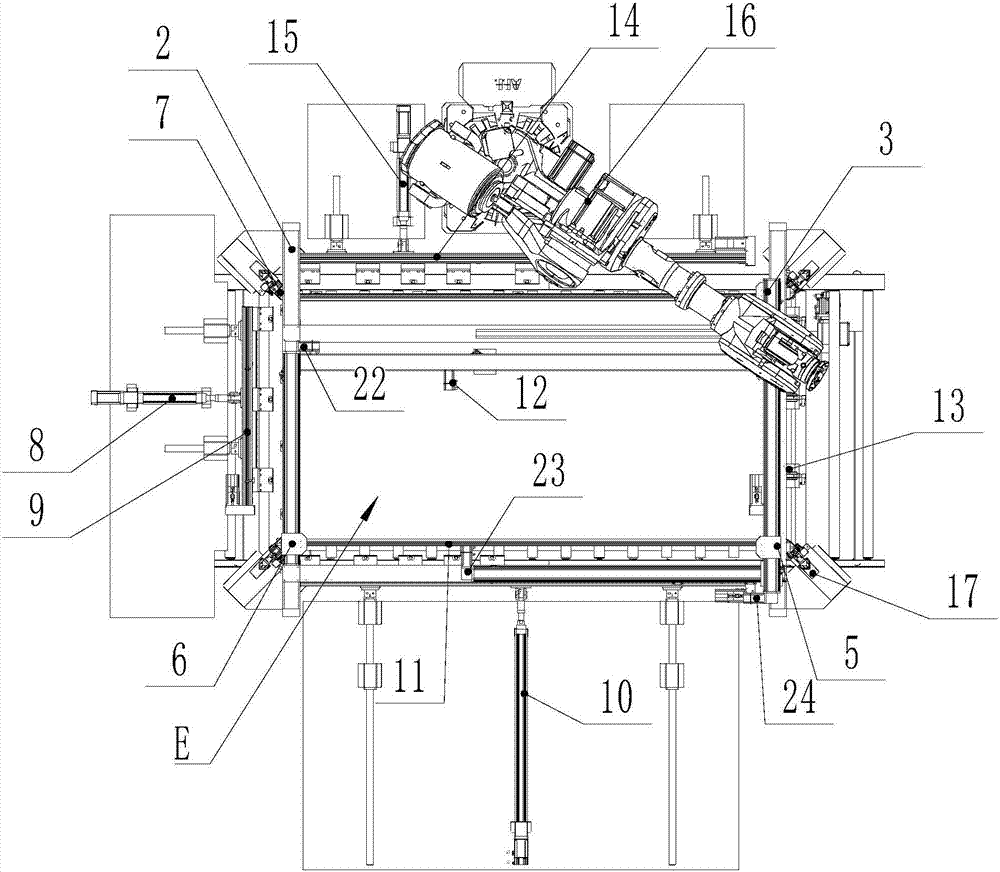

[0059] Such as Figure 1 to Figure 33 As shown, an automatic framing device for a solar heat collector is used for pre-assembling the bottom plate, the frame 25 and the corner code 26 of the solar heat collector. Wherein the bottom plate is a rectangular bottom plate, and the number of frames 25 is four, which are respectively left frame 25-1, right frame 25-2, front frame 25-3 and rear frame 25-4, frame 25 is provided with bottom plate slots, Upper jack and lower jack, the base plate slot of frame 25 directly inserts with base plate, and between the upper jack of adjacent frame 25 and between the lower jack all pass corner code 26 plug-in fits.

[0060] Such as Figure 1 to Figure 3 As shown, the automatic framing device includes a frame 1. A rectangular assembly area E is arranged on the frame 1. Below the assembly area E, there is a floor conveying device that horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com