Milling process damping calibration method based on operating modal analysis

A calibration method and working mode technology, applied in the direction of instruments, etc., can solve problems such as poor practicability and achieve good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

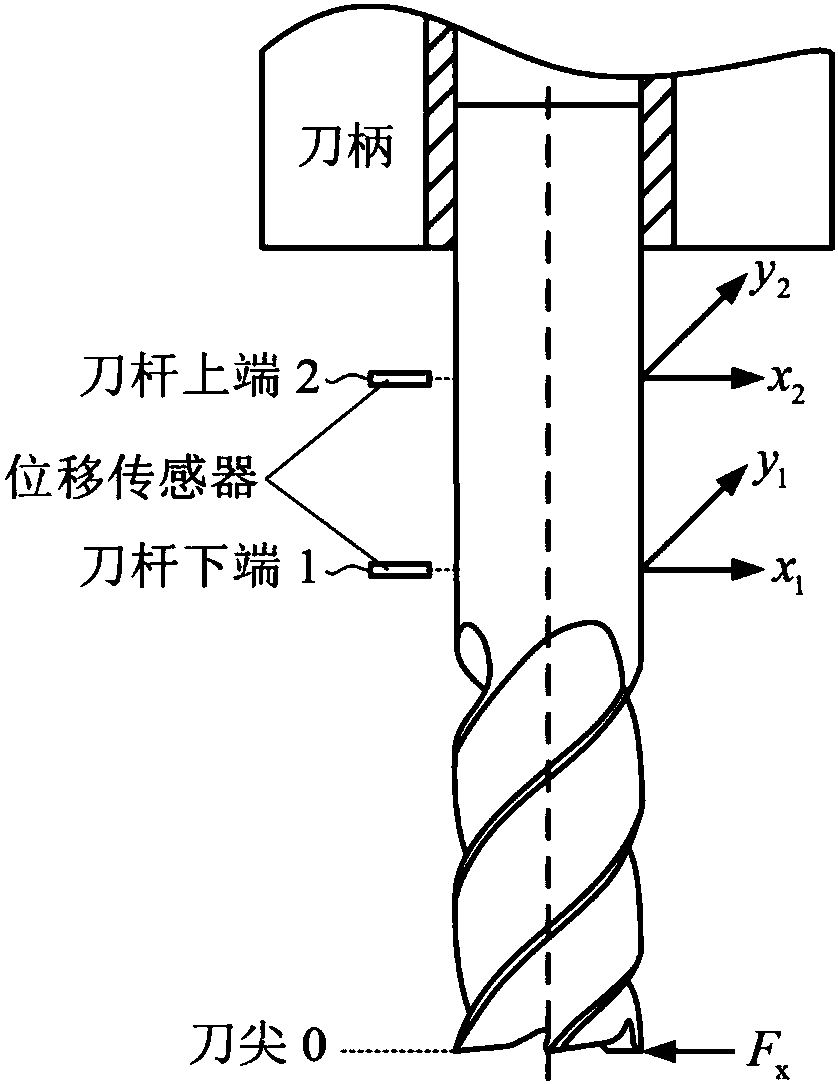

[0046] refer to Figure 1-6 . The specific steps of the milling process damping calibration method based on the working mode analysis in the present invention are as follows:

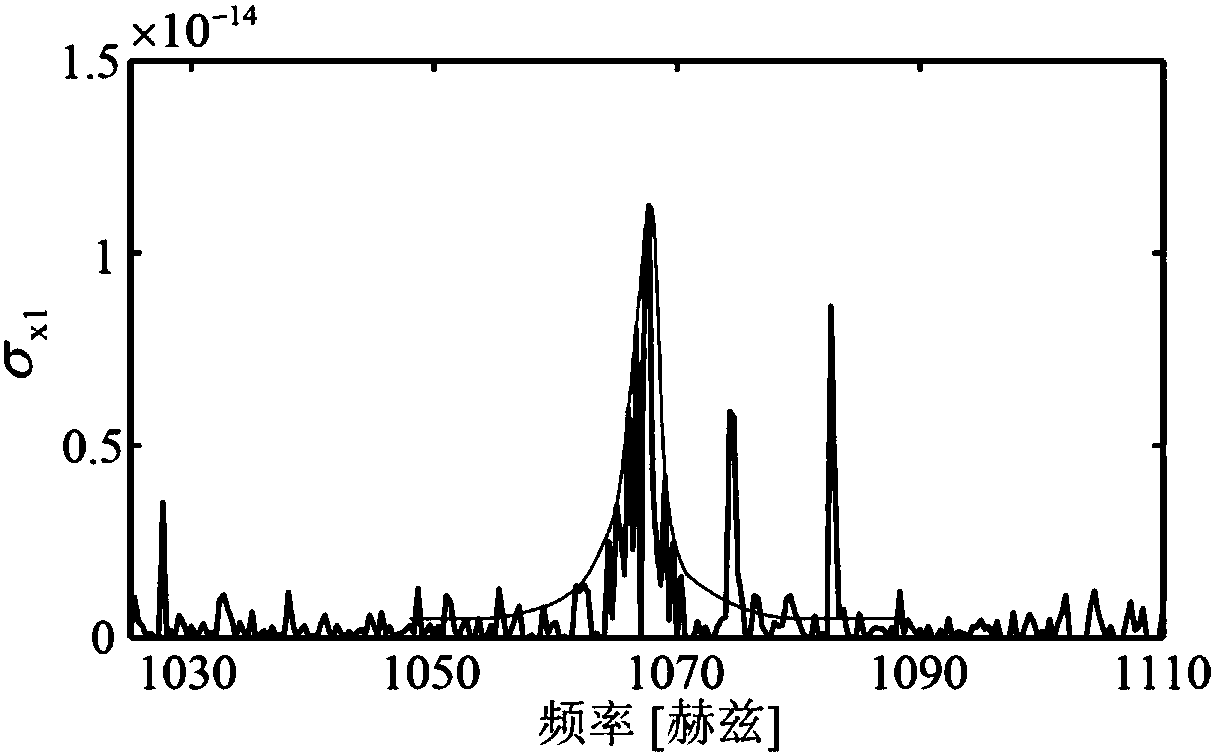

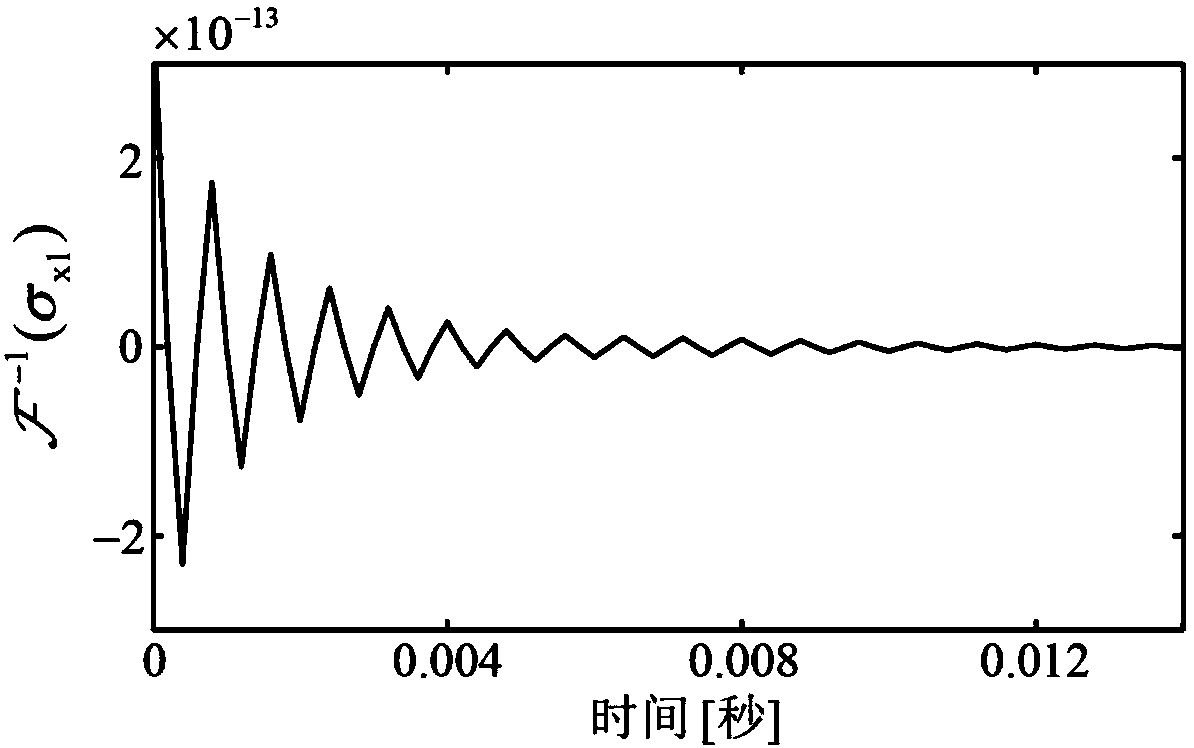

[0047] Step 1. Experimentally select a cemented carbide end mill with a radius of 6mm, a helix angle of 35°, a normal front angle of 10°, a relief angle of 5°, a radius of the tool tip arc of 20 μm, and a number of teeth of 4 in the three coordinates Vertical machining center performs down milling on aluminum alloy 7050-T7451. Attach the accelerometer to the tool tip 0, the lower end 1 of the tool bar and the upper end 2 of the tool bar, and strike the tool tip 0 with a force hammer, and extract the dominant mode parameters m in the x and y directions from the obtained frequency response curve x =0.3193kg, ζ sr,x = 1.79%, ω n,x = 1060Hz, and m y =0.3971kg, ζ sr,y = 2.35%, ω n,y = 1041Hz, where m x and m y is the modal mass at tip 0, ζ sr,x and ζ sr,y is the structural damping ratio at too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com