Device for detecting critical flow velocity and settlement rate of backfill slurry and method for detecting critical flow velocity and settlement rate of backfill slurry by using device

A technology of filling slurry and settlement rate, which is applied in the direction of measuring devices, flow characteristics, and analysis materials, can solve the problems of large errors, difficult filling slurry dynamic settlement detection and analysis, lack of dynamic settlement detection devices and methods, etc., to achieve Reliable and scientifically supported effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0033] 1. Detection method of critical flow velocity of filling slurry

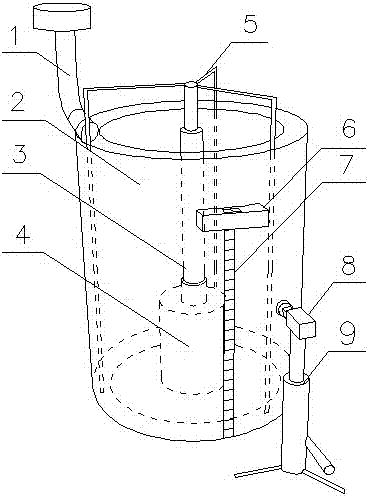

[0034] Fix the filling material, feed pipe 1, laser velocimeter 6, and scale 1 on the circular cylindrical barrel 2, and place the circular cylindrical barrel 2 outside the variable frequency speed regulating rotor 4, so that the frequency variable speed regulating rotor and the circular The cylindrical barrel is coaxial, lift the telescopic shaft 3 of the variable frequency speed-regulating rotor 4 to the position twice that of the cylindrical barrel, install the right-angle stirring rod 5, and lower the telescopic shaft 3 so that the right-angle stirring rod 5 touches the cylindrical barrel 2 At the bottom of the bottom, the right-angle stirring rod 5 is installed at an intersection angle of 120° and ensures that no silt dead angle is left during stirring; the position of the high-definition camera 8 is changed by adjusting the height of the hydraulic support 9, so that the high-definition camera can cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com