Vacuum degree adjustable cooked food vacuum cooling equipment

A technology of vacuum cooling and vacuum degree, applied in food preservation, food science, application, etc., can solve the problems of hard taste, dull color, moisture loss of meat, etc., and achieve the effect of controlling vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0010] It should be noted that the "connection" mentioned in this application and the words used to express "connection", such as "connected", "connected", etc., can refer to the direct connection between a certain component and another component, It can also mean that a certain component is connected to another component through other components.

[0011] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

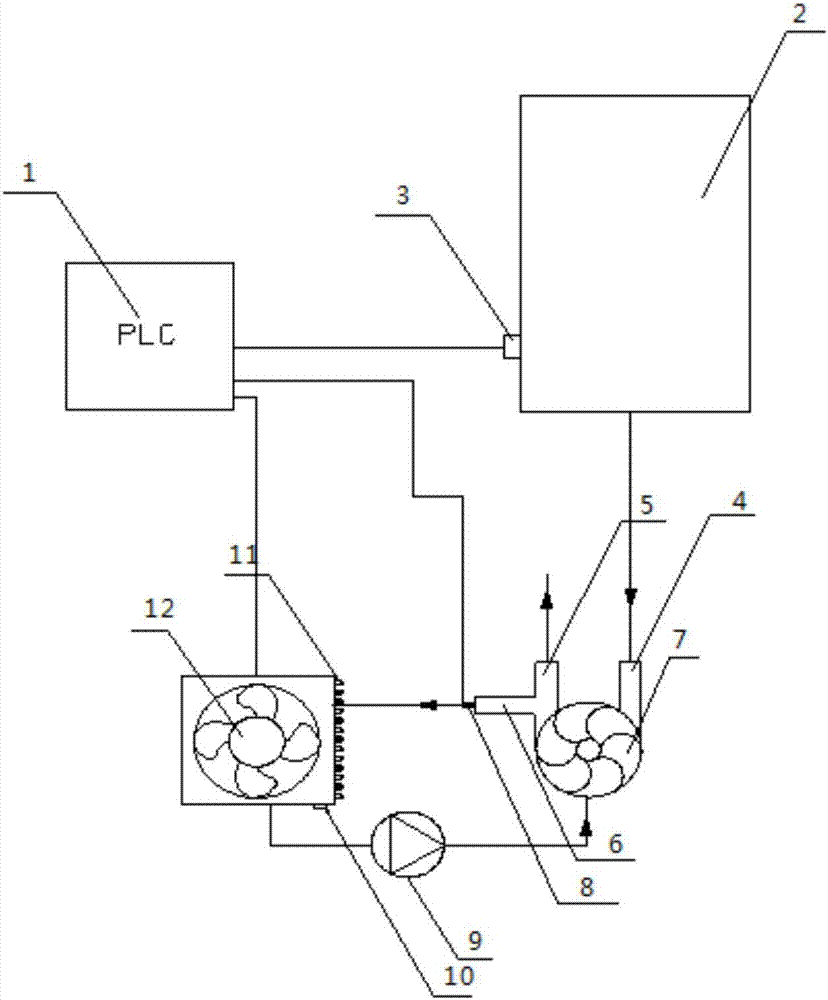

[0012] Such as figure 1 As shown, a vacuum cooling device for cooked food with adjustable vacuum degree of the present invention includes a PLC controller 1, a vacuu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap