Desulfurization tower

A desulfurization tower and tower body technology, which is applied in the field of air pollution control in the environmental protection industry, can solve the problem of low sulfur dioxide removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

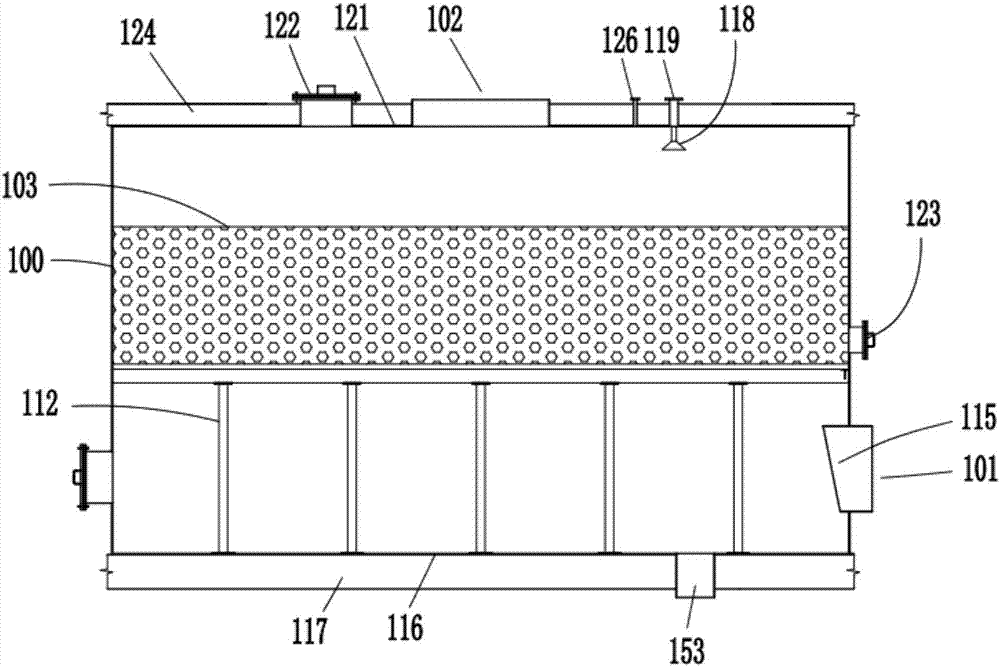

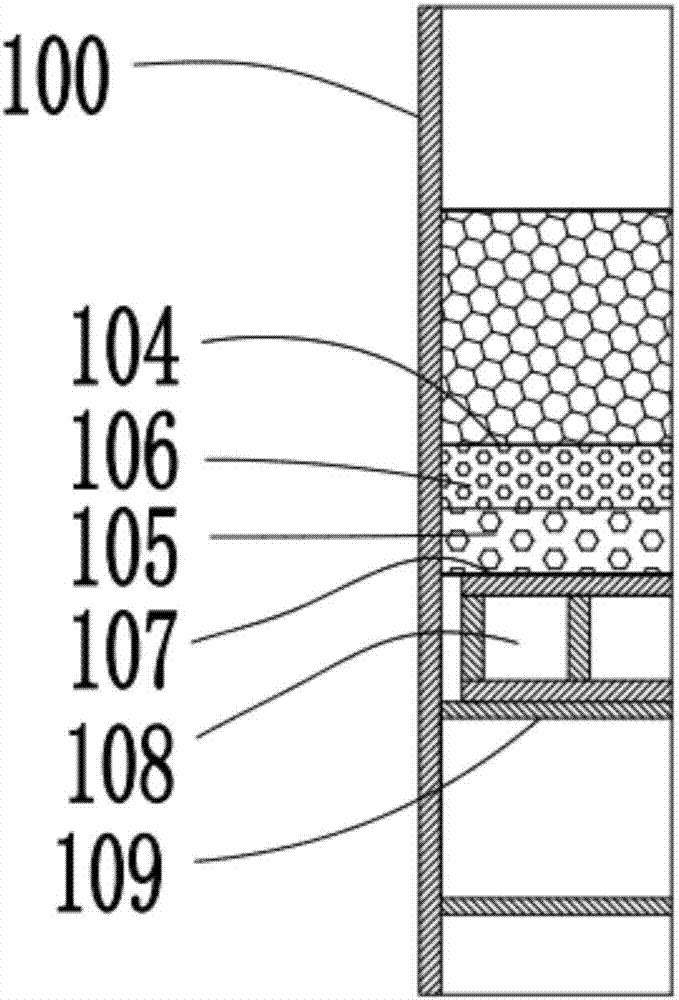

[0163] Example 1, such as Figure 1-13 Shown:

[0164] A filter layer assembly for a desulfurization tower. The filter layer assembly 103 is located between the flue gas inlet 101 and the flue gas outlet 102 of the desulfurization tower, so that the flue gas passes through the filter layer assembly 103 first, and then the flue gas The air outlet 102 is discharged. The filter layer assembly 103 includes a filter layer 132, and a plurality of flue gas passages for the flue gas to pass through the filter layer 132.

[0165] In the filter layer assembly 103 of the present application, in the filter layer 132 there are a number of channels for the flue gas to pass through. The flue gas entering the tower body 100 passes through these channels and then is discharged from the flue gas outlet 102. In this way, the flue gas can be greatly improved. The contact efficiency of the sulfur dioxide and the desulfurizing agent in the flue gas is further improved. The desulfurizing agent in this a...

Embodiment 2

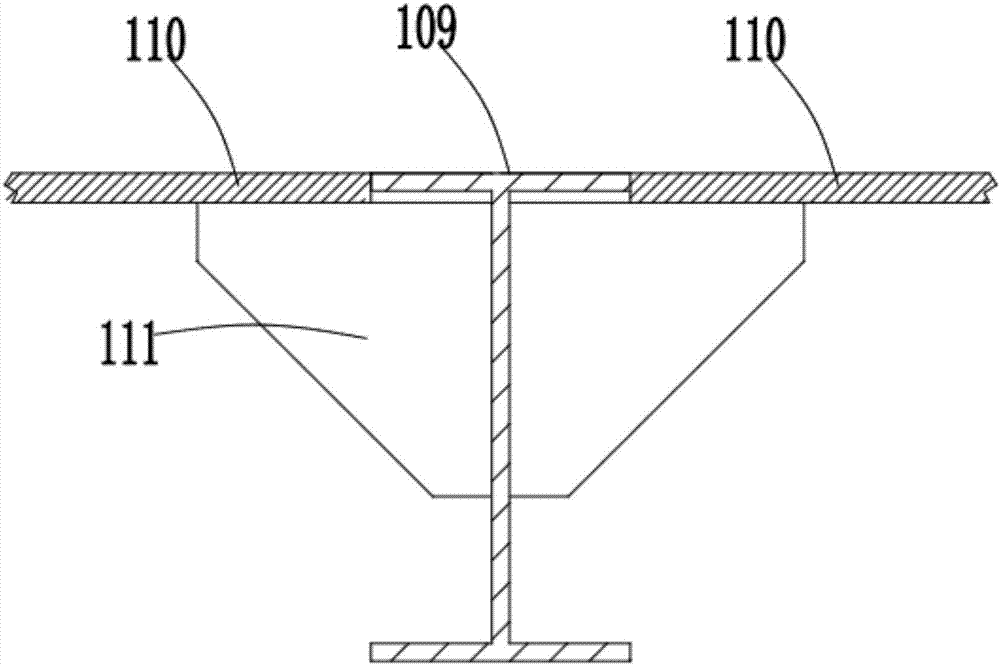

[0187] Example 2, such as Figure 1-13 Shown:

[0188] A catalyst support assembly for a desulfurization tower, the support assembly is arranged in the tower body 100 of the desulfurization tower, the support assembly is located below the filter layer assembly 103, and the support assembly is used to support the filter layer assembly 103. Separate the filter layer assembly 103 from the bottom of the tower body 100.

[0189] In this solution, the filter layer assembly 103 is separated from the bottom of the tower body 100 by supporting components. On the one hand, it is convenient for the flue gas to have enough space to fill the space below the filter layer assembly 103, and to prevent the smoke from only entering the smoke from close to The filter layer of the mouth part passes through, thereby ensuring the filtration efficiency of the sulfur dioxide of the filter layer.

[0190] Preferably, the supporting assembly includes a grid plate 108, the edge of the grid plate 108 is match...

Embodiment 3

[0207] Example 3, such as Figure 1-13 Shown:

[0208] The application also discloses a tower body for desulfurization tower,

[0209] A smoke inlet pipe 115 is connected to the flue gas inlet 101, one end of the smoke inlet pipe 115 extends into the tower body 100, and in the vertical direction, the smoke inlet pipe 115 located inside the tower body 100, There are occlusions above any part of the inner wall.

[0210] In this solution, there is a shelter above any part of the inner wall of the tower body 100, so as to prevent the liquid or other materials above from falling into the flue gas pipe 115 and affecting the flue gas transportation. In the solution of this method, the vertical In the straight direction, the smoke inlet pipe 115 located inside the tower body 100 has a shield above any part of its inner wall. The shield can be arranged to incline the smoke inlet pipe 115 so that the port of the smoke inlet pipe 115 is inclined. , So that the upper part of the port forms th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com