A high-power multi-stage stepped horn

A horn and step-type technology, applied in the field of mechanical vibration, can solve problems such as increased processing difficulty, increased processing cost, and complex design, and achieve the effects of reducing processing difficulty, reducing processing cost, and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

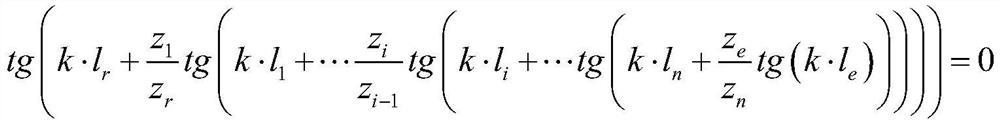

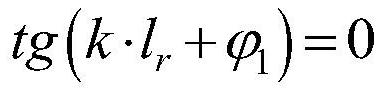

Method used

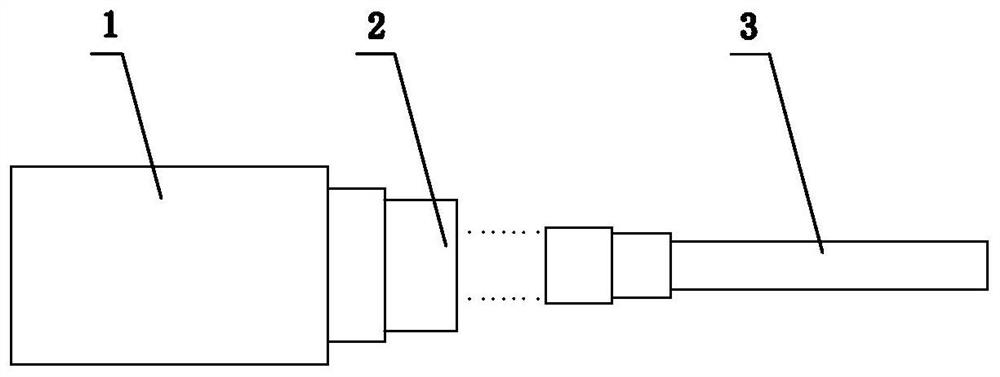

Image

Examples

Embodiment 1

[0039] In this embodiment, the length L of the horn is 130mm, the number of stages of the transition section 2 is n=2, and the total length of the transition section 2 is 1 / 20 of the length L of the horn, that is, the total length of the transition section 2 is 6.5mm, the length of a single step is 3.25mm, the length of input rod 1 and output rod 3 are both equal to 61.75mm, and the diameter of input rod 1 is D r Take 0.4 times the length L of the horn, which is 52mm, and the diameter D of the section 3 of the output rod e Take 16mm, the diameter D of the two steps in the middle transition section 2 1 , D 2 The uniform changes are taken as 40mm and 28mm respectively.

[0040] The material for making the horn is 45# steel. Calculated by analytical method, the longitudinal vibration frequency is 20.6kHz, the amplification factor M p = 10.5.

[0041] Using ANSYS finite element calculation, the longitudinal vibration frequency is 19.2kHz, the amplification factor is 9.9, and ...

Embodiment 2

[0044] In this embodiment, the length L of the horn is unchanged at 130 mm, and the cross-sectional diameters of the input rod 1 and the output rod 3 are not changed to 26 mm and 8 mm. The number of steps in the transition section 2 is n=5, and the total length of the transition section 2 is 1 / 13 of the horn length L, which is 10mm, then the length of a single step is 2mm, and the lengths of the input rod 1 and the output rod 3 are both equal to 60mm , the steps of the intermediate transition section 2 change uniformly, and the cross-sectional diameter D of the five steps of the intermediate transition section 2 1 , D 2 , D 3 , D 4 , D 5They are 46mm, 40mm, 34mm, 28mm, and 22mm in turn.

[0045] The material for making the horn is 45# steel. Calculated by the analytical method, the longitudinal vibration frequency is 20.8kHz, and the amplification factor M p = 10.4.

[0046] Using finite element calculation, the longitudinal vibration frequency is 19.5kHz, the amplifica...

Embodiment 3

[0049] In this embodiment, the length L of the horn is unchanged at 130 mm, and the cross-sectional diameters of the input rod 1 and the output rod 3 are not changed to 26 mm and 8 mm. The number of 2 stages in the transition section is n=8, and the total length of the transition section 2 is 1 / 10 of the horn length L, which is 13mm, then the length of a single stage is 1.625mm, and the lengths of input rod 1 and output rod 3 are both equal to 58.5 mm, the 2 steps in the middle transition section change evenly, the diameter D of the 28 steps in the middle transition section 1 , D 2 , D 3 , D 4 , D 5 , D 6 , D 7 , D 8 They are 48mm, 44mm, 40mm, 36mm, 32mm, 28mm, 24mm, 20mm, respectively.

[0050] The material for making the horn is 45# steel. Calculated by analytical method, the longitudinal vibration frequency is 21.0kHz, the amplification factor M p = 10.3.

[0051] Using finite element calculation, the longitudinal vibration frequency is 19.8kHz, the amplification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com