Large eccentric load multifunctional forging hydraulic machine

A kind of partial load, multi-function technology, applied in the field of forging machinery, can solve the problems of workpiece quality and production efficiency, the workpiece cannot meet the requirements of use, shorten the service life of hydraulic presses, etc., to improve the quality of workpieces and production efficiency, and prolong the service life of equipment , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

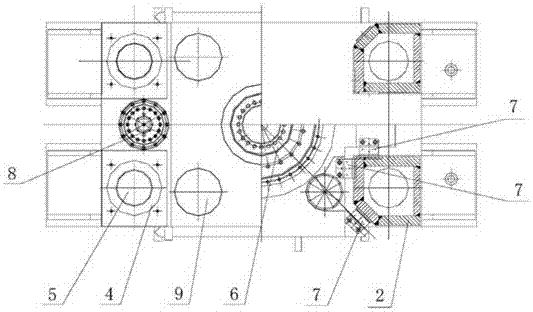

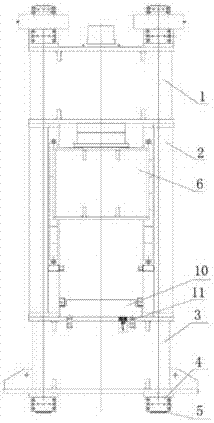

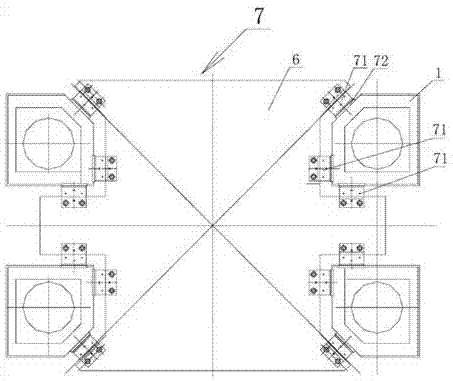

[0028] see Figure 1-Figure 5 , a large eccentric load multifunctional forging hydraulic press, including a closed combination frame body composed of an upper beam 1, a lower beam 3, four columns 2, a tie rod 5 and a lock nut 4, and the upper beam is fixedly equipped with Belt cylinder slide block 6, side cylinder 9 and return stroke cylinder 8, the other end of side cylinder and return stroke cylinder is connected with belt cylinder slide block, is provided with mobile workbench 10 on the lower crossbeam, and described belt cylinder slide block is connected with four columns A cooperating guide device 7 is provided, and the guide device includes a guide rail assembly 71 arranged at the four corners of the cylinder block and a fixed guide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com