Calibration system and method for industrial robot

A technology of industrial robots and calibration systems, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as unreasonable economy and unfeasible production, and achieve the effects of flexible movement, sufficient movement, and improved reliability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

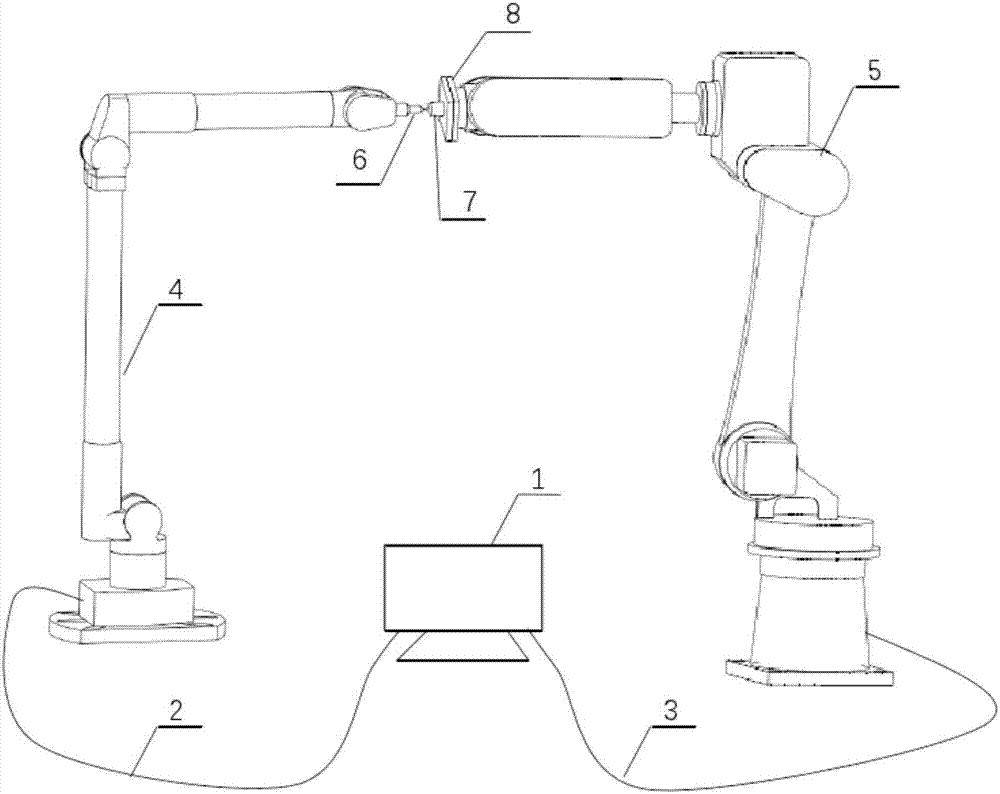

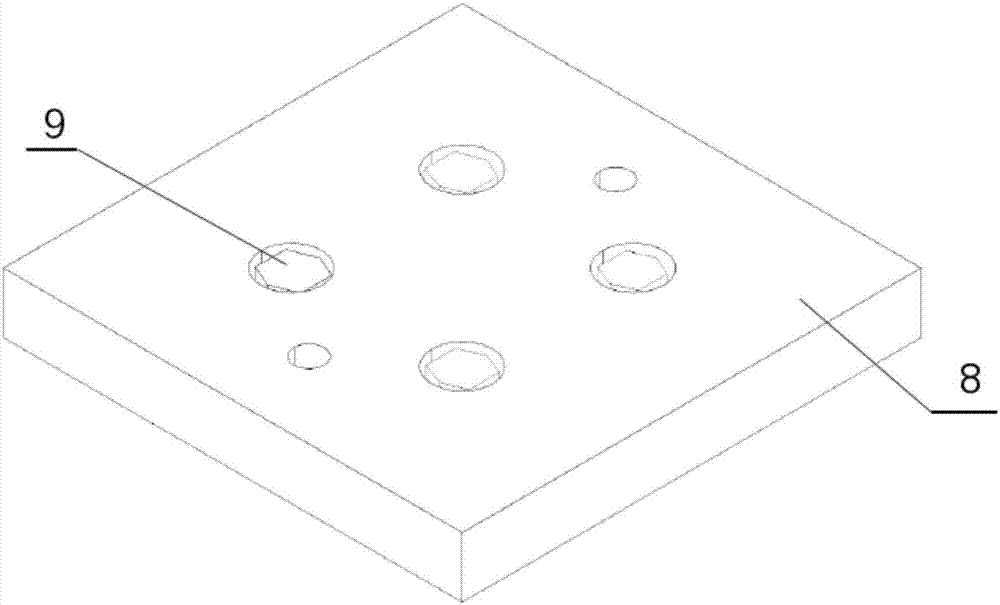

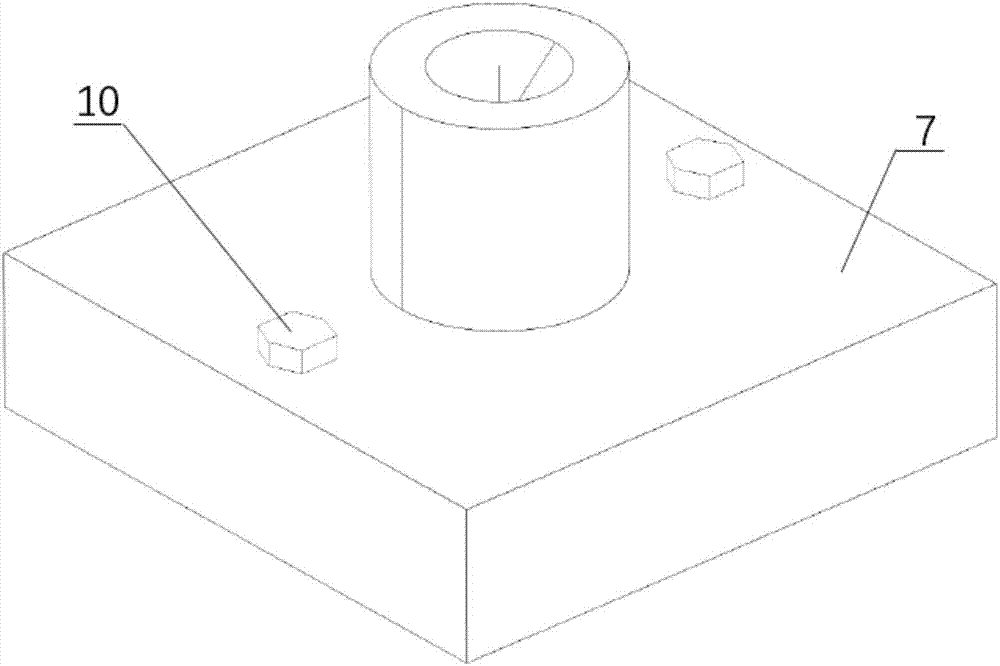

[0034] Embodiment 1: as Figure 1-4 As shown, a calibration system for an industrial robot includes a computer 1, an articulated arm measuring machine cable 2, an industrial robot cable 3, an articulated arm measuring machine 4, an industrial robot 5, a tapered hole 7 and a connecting plate 8,

[0035] The computer 1 contains data acquisition software; wherein the industrial robot 5 is connected and communicated with the computer 1 through the industrial robot cable 3, and the articulated arm measuring machine 4 is connected and communicated with the computer 1 through the articulated arm measuring machine cable 2; the data acquisition is controlled by the computer 1 The software collects the end positions of the industrial robot 5 and the joint rotation angles of the articulated arm measuring machine 4 (6 rotation angles θ 1,i ,θ 2,i ,θ 3,i ,θ 4,i ,θ 5,i ,θ 6,i ); the connecting plate 8 is connected to the flange at the end of the sixth joint of the industrial robot 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com