Micro-channel phase change heat transfer test stand and micro-channel phase change heat transfer test platform

A technology of micro-channel and test bench, which is applied in the field of micro-channel phase change heat transfer test bench and test platform, can solve the problems that the initial state cannot be guaranteed, the error of phase change thermal characteristic parameters is large, and the test results are affected, so as to avoid Effects of heat loss, improved test accuracy, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0047] The invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth again, but rather these embodiments are provided so that this disclosure will be thorough and complete. In the drawings, the size and relative sizes of structures and regions may be exaggerated for clarity.

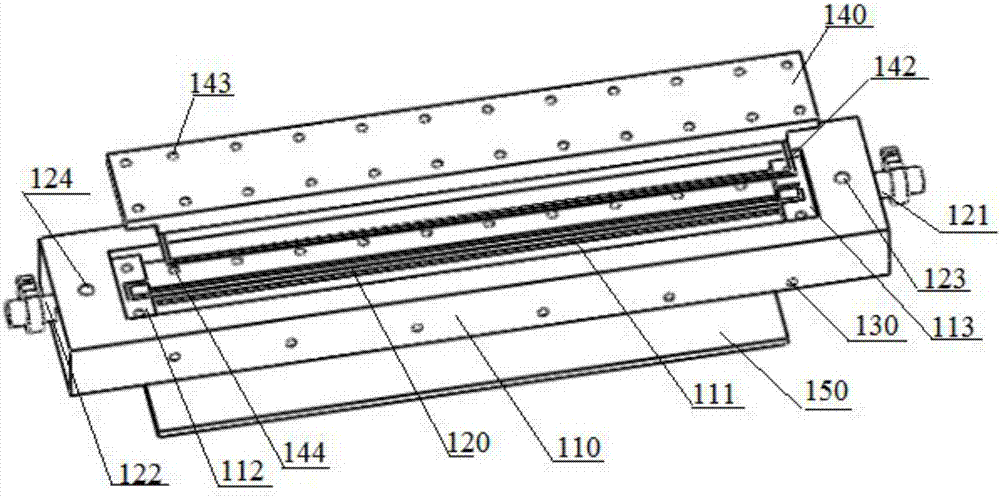

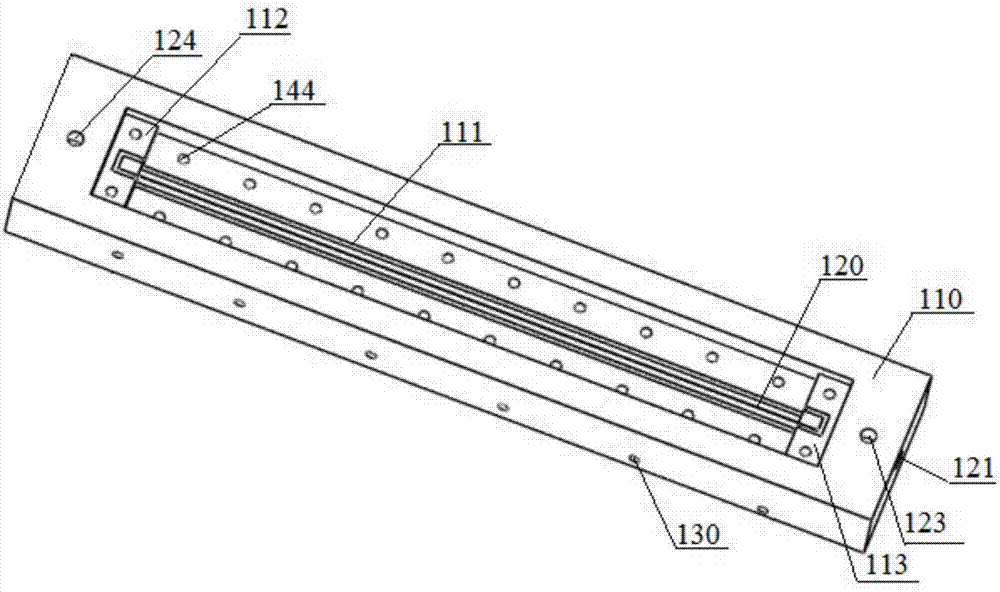

[0048] Such as Figure 1-6As shown, the present invention provides a microchannel phase change heat transfer experimental platform 100, comprising: a base 110, on which a rectangular groove is arranged; a first boss 112 and a second boss 113, which are formed from the groove The bottom surface of the first boss 112 and the second boss 113 extend upwards, the upper surface of the first boss 112 and the second boss 113 are lower than the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com