A combined axicon device

An axicon and combined technology, applied in the laser field, can solve the problems of increasing processing cost, increasing the difficulty of component processing, limiting non-diffracting beams, etc., and achieving the effect of reducing processing difficulty and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

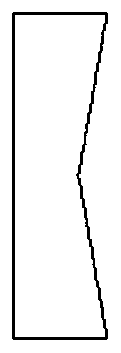

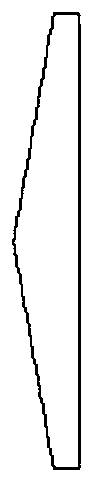

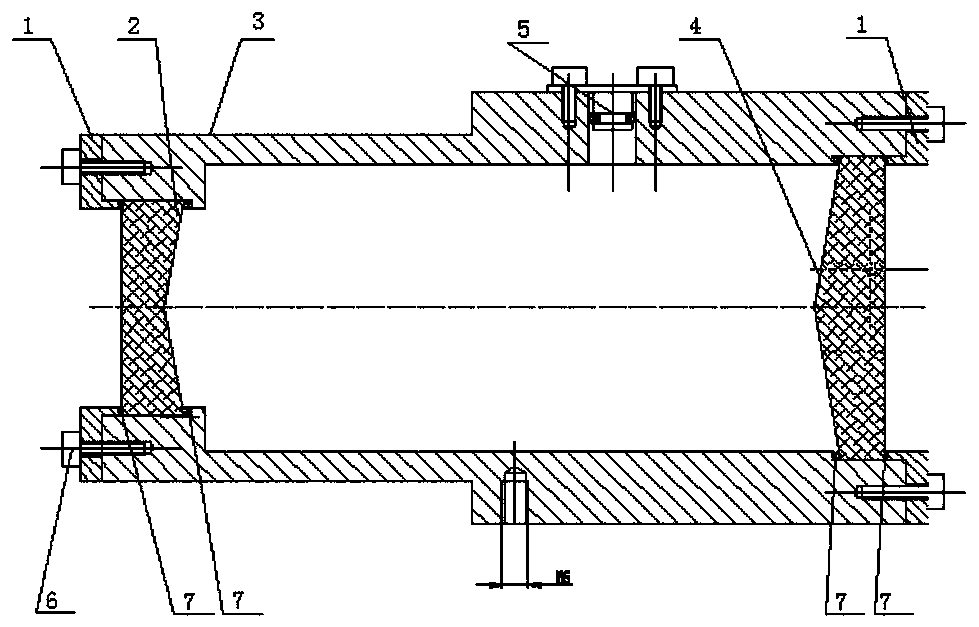

[0042] like figure 2 and Figure 4 As shown, the combined axicon device structure of the present embodiment includes a gland 1, a negative axicon 2, a positive axicon 4, between the negative axicon 2 and the positive axicon 4, and with the negative axicon 2 and the positive axicon The shape of 4 matches the optical medium, the lens barrel 3, the sealing plug 5, the nut 6 and the gasket 7;

[0043] The concave cone surface of described negative axicon 2 is opposite to the convex cone surface of positive axicon 4; Wherein Fig. 1 (a) is negative axicon structure schematic diagram of the present invention; Fig. 1 (b) is positive axicon structure of the present invention schematic diagram;

[0044] The negative axicon 2 and the positive axicon 4 are respectively fixed at the two ends of the lens barrel 3, and the contact surfaces of the negative axicon 2, the positive axicon 4 and the lens barrel 3 are provided with gaskets 7;

[0045] The lens barrel 3, that is, the space betwe...

Embodiment 2

[0049] like image 3 and Figure 5As shown, the combined axicon device structure of the present embodiment is designed as a slidable structure, including a gland 1, a negative axicon 2, a positive axicon 4, between the negative axicon 2 and the positive axicon 4, and with the negative The optical medium whose shape matches the axicon 2 and the positive axicon 4, the lens barrel 3, the sealing plug 5, the nut 6, the gasket 7 and the sliding cylinder 8;

[0050] The concave cone surface of described negative axicon 2 is opposite to the convex cone surface of positive axicon 4; Wherein Fig. 1 (a) is negative axicon structure schematic diagram of the present invention; Fig. 1 (b) is positive axicon structure of the present invention schematic diagram;

[0051] The sliding tube 8 is matched and nested in the lens barrel 3;

[0052] The negative axicon 2 is fixed on the nesting end of the slide tube 8 and the lens barrel 3, and the positive axicon 4 is fixed on the other end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com