Low-EMI asymmetrical centre tap rectification circuit

A technology of center tap and rectifier circuit, which is applied in the direction of electrical components, adjusting electric variables, high-efficiency power electronic conversion, etc., can solve the problems of long-time switching tubes on the primary side, electromagnetic interference, etc., and achieve improved conversion efficiency, reduced volume, reduced Effect of small dead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

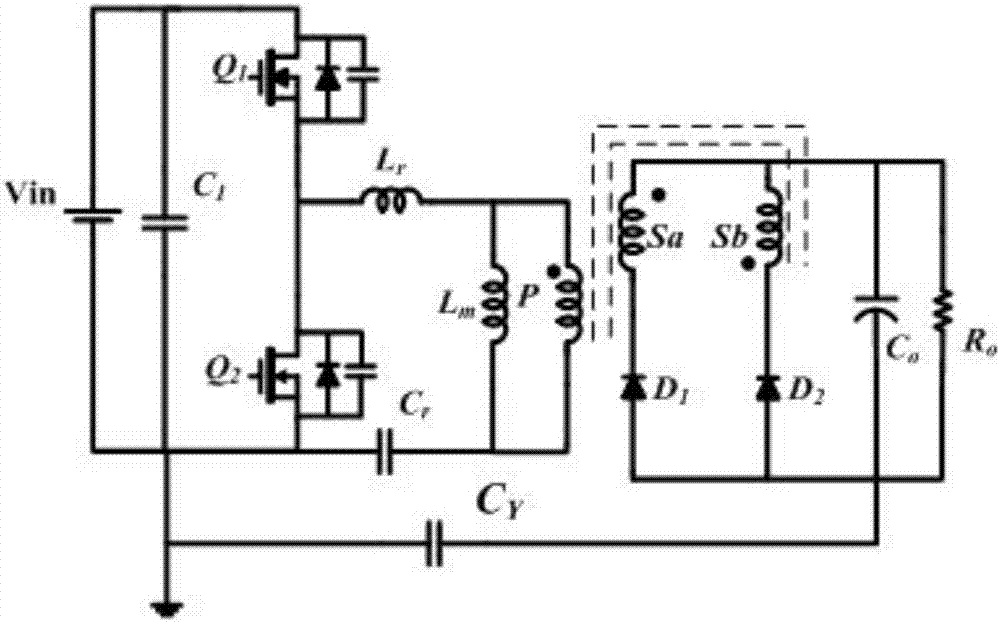

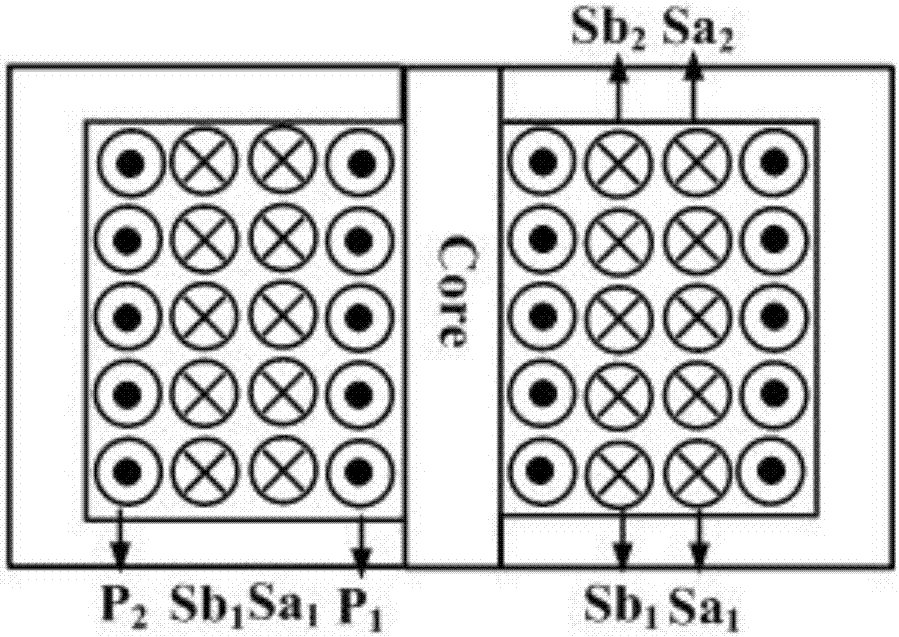

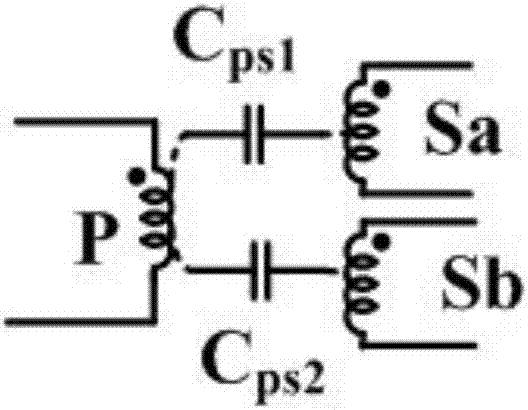

[0032] The low-EMI asymmetric center-tapped rectifier circuit in the present invention has a half-bridge LLC topology as the primary side, and a center-tap rectifier circuit as the rear stage, including a set of bridge arms, a resonant inductor Lr, a resonant capacitor Cr, two rectifier diodes D1, D2, and a power transformer T 1 ; Power transformer T 1 Including the primary winding P, the first secondary winding Sa and the second secondary winding Sb, the power transformer T 1 The primary and secondary windings adopt a staggered winding structure, and the end of the transformer winding with the same name is defined as the positive end and the other is the negative end; it is characterized in that:

[0033] Among the two rectifier diodes D1 and D2, the first rectifier diode D 1 The cathode of the second secondary winding Sb is connected to the output filter capacitor C 0 The positive end of the second rectifier diode D 2 The anode of the first secondary winding Sa is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com