A stretchable or bendable composite circuit system and its preparation method

A composite circuit and circuit system technology, applied in the direction of printed circuit manufacturing, printed circuit, circuit substrate materials, etc., can solve problems such as complex equipment and circuit damage, and achieve reduced deformation field, easy pre-deformation, compatibility and matching sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

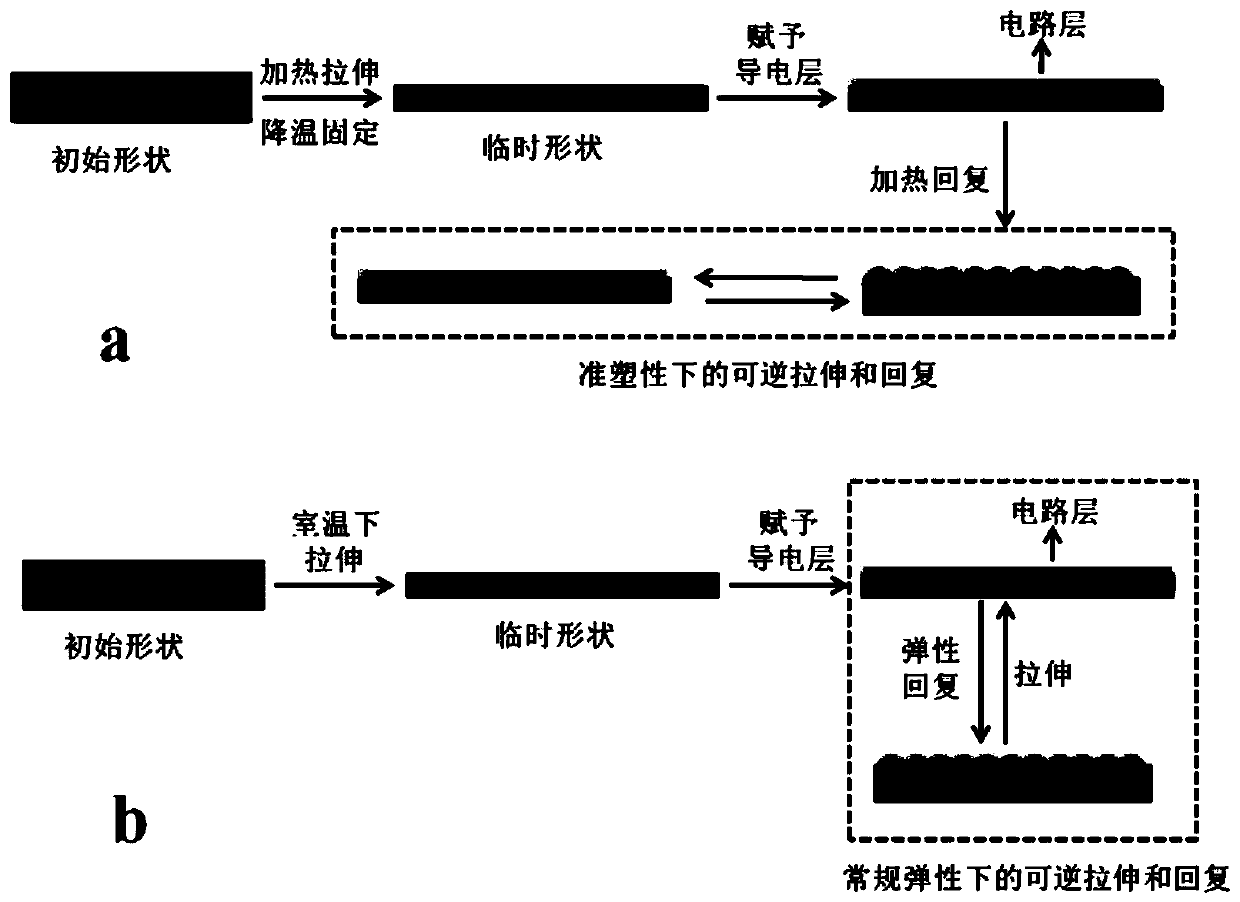

[0026] The invention discloses a method for preparing a stretchable or bendable composite circuit system, which comprises the following steps:

[0027] S1: Preparation of elastic shape memory polymer;

[0028] S2: pre-stretching the elastic shape memory polymer prepared in step S1 by 10%-150% at 60-120°C, and then cooling down to room temperature to fix the temporary shape of the elastic shape memory polymer;

[0029] S3: Prepare a circuit system by spraying, pasting or circuit printing process inside or on the surface of the pre-stretched elastic shape memory polymer obtained in step S2;

[0030] S4: heating triggers the shape recovery of the elastic shape memory polymer treated in step S3, causing the circuit system to form wrinkles, and a stretchable or bendable composite circuit system is obtained.

[0031] In step S1, the hot melt adhesive component is added to the liquid silicone elastomer, fully stirred evenly at 85°C, and then cooled to room temperature, then the curi...

Embodiment 1

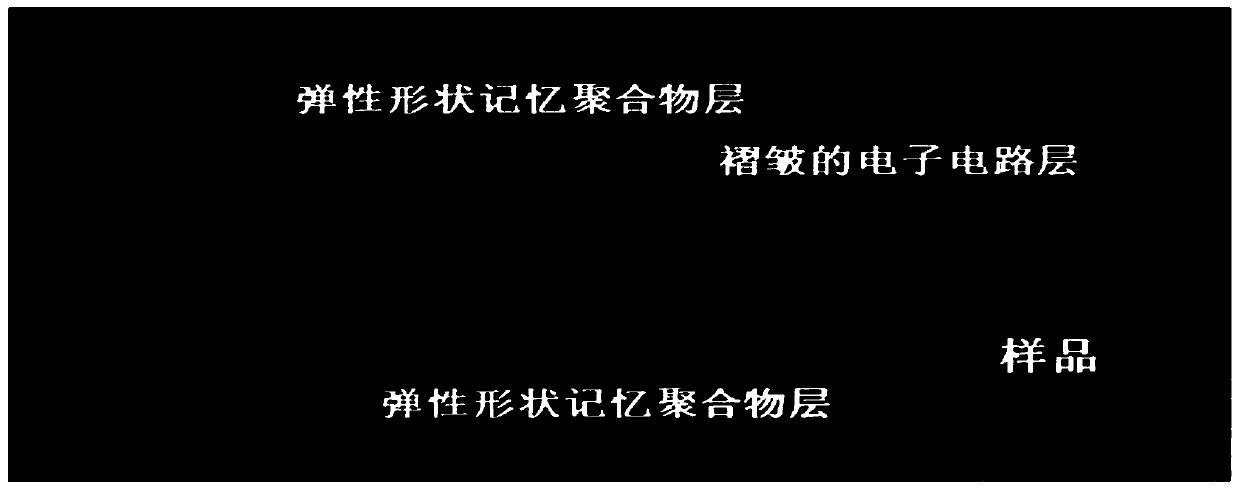

[0046] Prepare two pieces of silica gel-type elastic shape memory polymers, respectively stretch the two pieces of polymers uniaxially by 30% at a higher temperature (such as 100° C.), and then cool down to room temperature to fix the temporary shape. After the circuit is printed on the surface of a pre-stretched polymer, the two sheets of polymer are glued together with silicone, with the circuit in the middle. After the silicone has cured, heating again triggers deformation recovery and wrinkles the circuit. The double-layer unidirectional pre-stretched flexible composite circuit system is shown in figure 2 .

Embodiment 2

[0048] Through the following four steps, a single-layer unidirectional pre-stretched shape-memory polyurethane type stretchable / bendable composite circuit system is prepared. Specific steps include:

[0049] (1) A piece of shape memory polyurethane film is prepared by solvent evaporation method or hot pressing method;

[0050] (2) Pre-stretch 20% in one direction at 80°C, and then lower it to room temperature to fix the temporary shape;

[0051] (3) Prepare circuits by processes such as spraying on the surface of the pre-stretched polyurethane film;

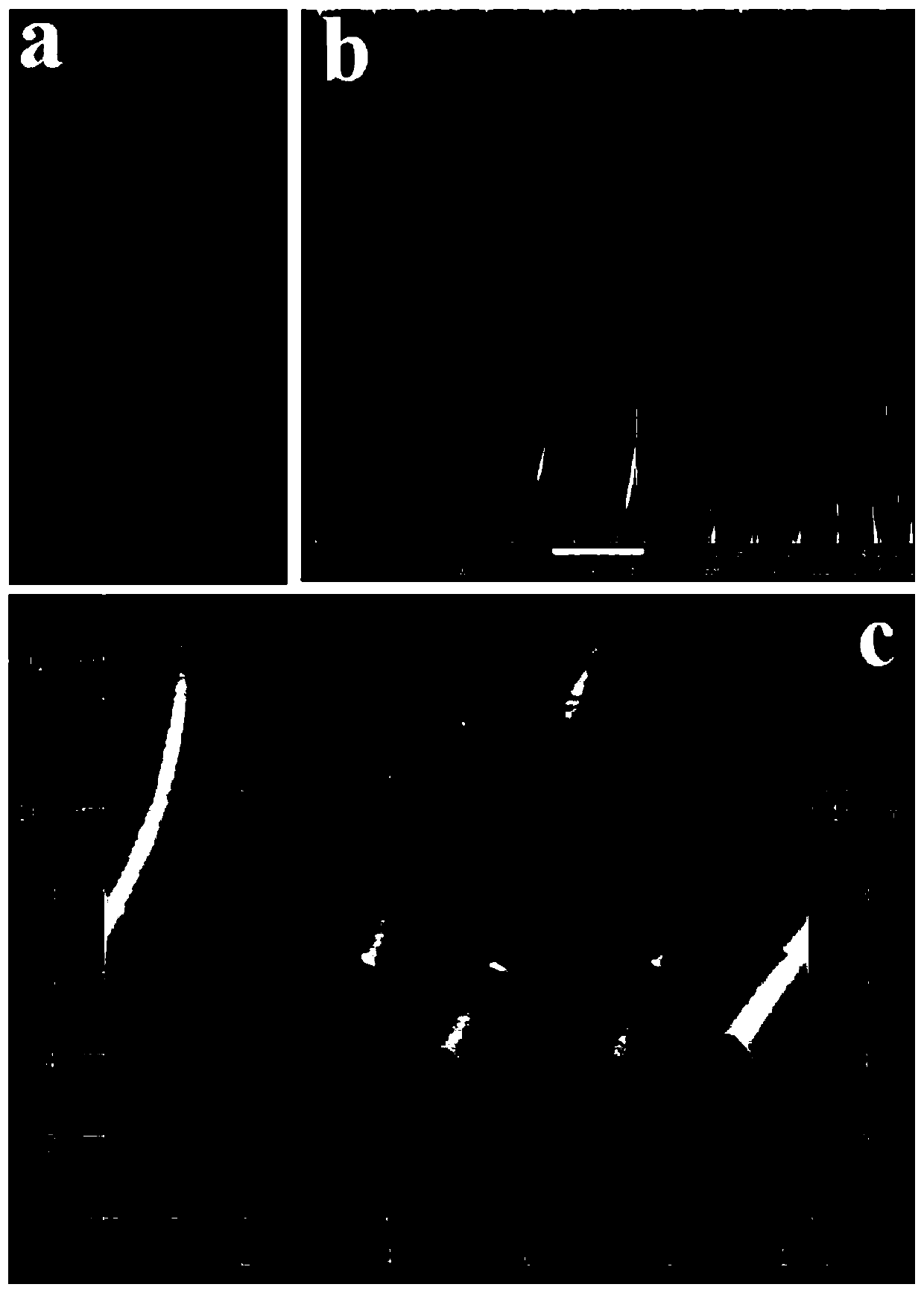

[0052] (4) Heating-triggered shape recovery leads to the formation of micro-nano wrinkles in the circuit. A series of micro-nano wrinkled surfaces produced by shape-memory shrinkage have been prepared. The optical photographs, scanning electron microscope and atomic force microscope photographs of representative samples are as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com