Ni based target material with excellent sputtering properties

A sputtering target, nix-fey-coz technology, used in sputtering, cathode sputtering applications, sputtering coating, etc., can solve problems such as inability to correspond to the seed layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail.

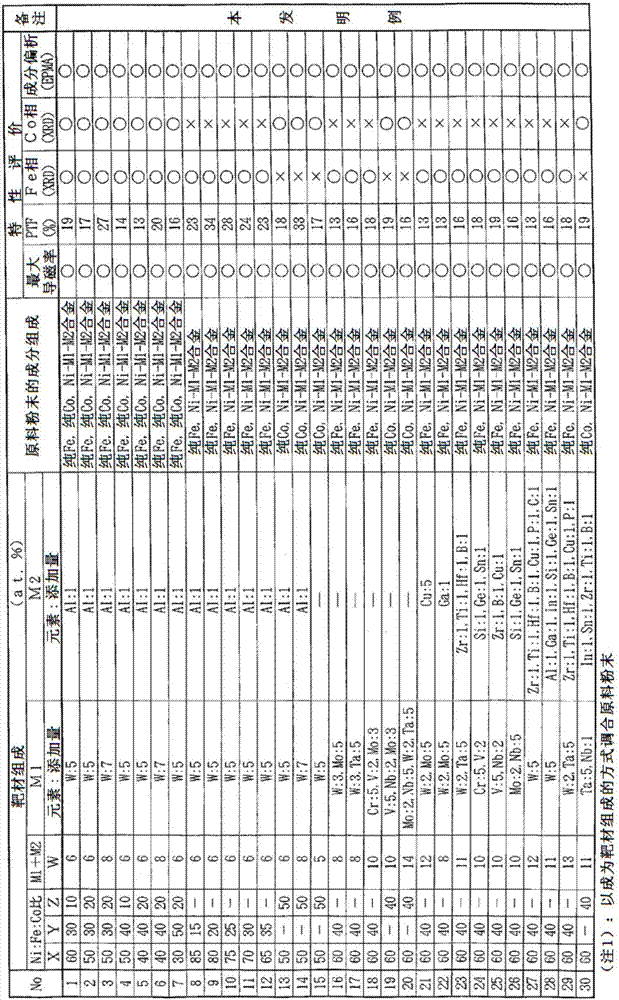

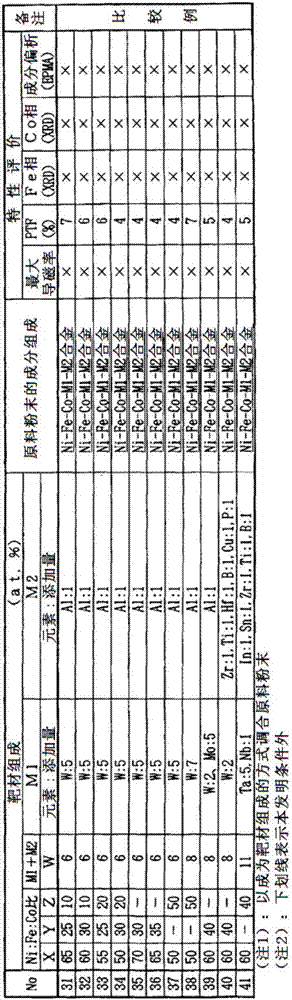

[0021] The present invention relates to a Ni-based sputtering target, which contains (Ni X -Fe Y -Co Z )-M alloy (here, X represents the ratio of Ni content to the total content of Ni, Fe and Co, Y represents the ratio of Fe content to the total content of Ni, Fe and Co, and Z represents the ratio of Co content to Ni, Fe and Co. The ratio of the total content of Fe and Co.) The Ni-based sputtering target formed, is characterized in that,

[0022] (Ni X -Fe Y -Co Z )-M alloys (hereafter referred to as "Ni-Fe-Co-M alloys" in some cases.), as the M element, containing one or two or more selected from W, Mo, Ta, Cr, V, Nb The total amount of M1 elements is 2-20 at.%, one or more M2 elements selected from Al, Ga, In, Si, Ge, Sn, Zr, Ti, Hf, B, Cu, P, C, Ru Total 0~10at.%,

[0023] The balance consists of Ni, Fe, Co and unavoidable impurities, and,

[0024] When X+Y+Z=100, 20≤X≤98, 0≤Y≤50, 0≤Z≤60, and,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com