Security filter convenient for filter element replacement

A technology of security filter and replacement of filter element, which is applied to fixed filter element filter, membrane filter, filtration and separation, etc., can solve the problems of time-consuming and labor-intensive filter element with large flow, heavy manual operation workload, and high labor cost. To achieve the effect of saving time and effort in disassembling the filter element, preventing the impact of subsequent equipment and water quality, and saving time and effort in installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

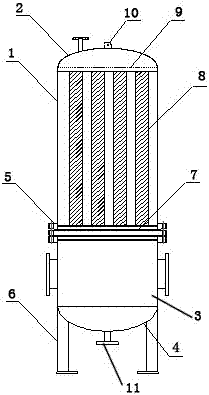

[0011] A security filter for easy filter element replacement, comprising an upper casing 1, an upper top cover 2, a lower casing 3, a lower bottom cover 4, a flange ring 5, legs 6, a porous plate 7, a filter element 8 and a fixed pressure plate 9 , the upper casing 1 and the upper top cover 2 are integrally connected by welding, the center of the upper top cover 2 is provided with a lifting hole 10; the upper casing 1 is provided with several filter elements 8, and the lower ends of the filter elements 8 are Installed on the perforated plate 7, the upper end is provided with a fixed pressure plate 9; the perforated plate 7 is connected to the lower shell 3 by the flange ring 5; the lower shell 3 and the lower bottom cover 4 are integrally connected by welding, so The lower bottom cover 4 is fixed on the support leg 6, the center of the lower bottom cover 4 is provided with a water outlet 11, the length of the filter element 8 is the same as that of the upper casing 1, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com