Agar culture medium preparation system

An agar medium and a preparation system technology, applied in the field of agar medium preparation systems, can solve the problems of high investment cost, technical lag, poor use effect, etc., and achieve the effects of low investment cost, reasonable structure design and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

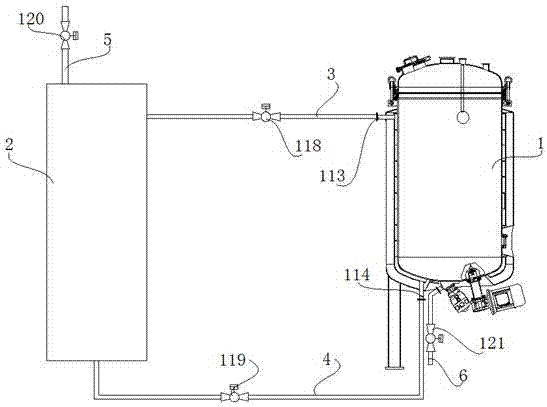

[0038] An agar medium preparation system, which includes a batching tank device 1, a water tank 2 and a pipeline system, the pipeline system includes a first water pipeline 3, a second water pipeline 4, a medium supply pipeline 5 and a sewage pipeline 6;

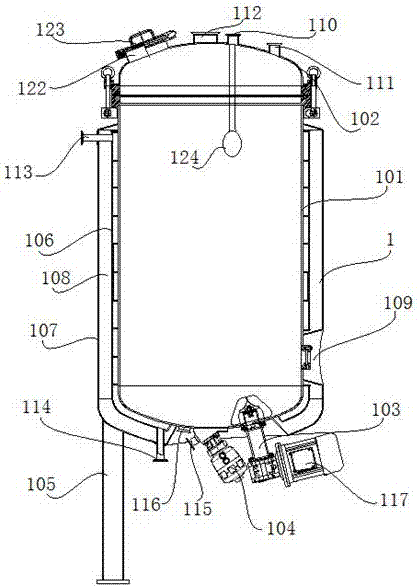

[0039] The batching tank device 1 comprises a batching tank body 101, a tank body cover 102, a magnetic stirring device 103 for stirring the agar medium in the batching tank body, a discharge valve 104 and a supporting leg 105, and the tank body cover 102 is arranged on the batching tank Above the main body 101, a diversion belt interlayer 106 is provided on the outside of the batching tank body 101, a butterfly head 107 is provided outside the diversion belt interlayer 106, and an insulating layer 108 is provided between the butterfly head 107 and the diversion belt interlayer 106, One side of the batching tank body 101 is provided with a pH meter test port 109 and a temperature test port 116, the supporting leg 105 is fixed...

specific Embodiment 2

[0043] An agar medium preparation system, which includes a batching tank device 1, a water tank 2 and a pipeline system, the pipeline system includes a first water pipeline 3, a second water pipeline 4, a medium supply pipeline 5 and a sewage pipeline 6;

[0044] The batching tank device 1 comprises a batching tank body 101, a tank body cover 102, a magnetic stirring device 103 for stirring the agar medium in the batching tank body, a discharge valve 104 and a supporting leg 105, and the tank body cover 102 is arranged on the batching tank Above the main body 101, a diversion belt interlayer 106 is provided on the outside of the batching tank body 101, a butterfly head 107 is provided outside the diversion belt interlayer 106, and an insulating layer 108 is provided between the butterfly head 107 and the diversion belt interlayer 106, One side of the batching tank body 101 is provided with a pH meter test port 109 and a temperature test port 116, the supporting leg 105 is fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com