Physical simulator of thick oil thermal extraction based on vacuum method and working method of physical simulator

A technology of thermal recovery and working method of heavy oil, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., which can solve the problems of inability to truly reflect the thermal recovery effect, high steam heat loss, and unsatisfactory steam heat transfer and heat preservation treatment and other problems, to achieve the effect of authenticity and reliability of experimental results, reduction of errors, and excellent vacuum insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

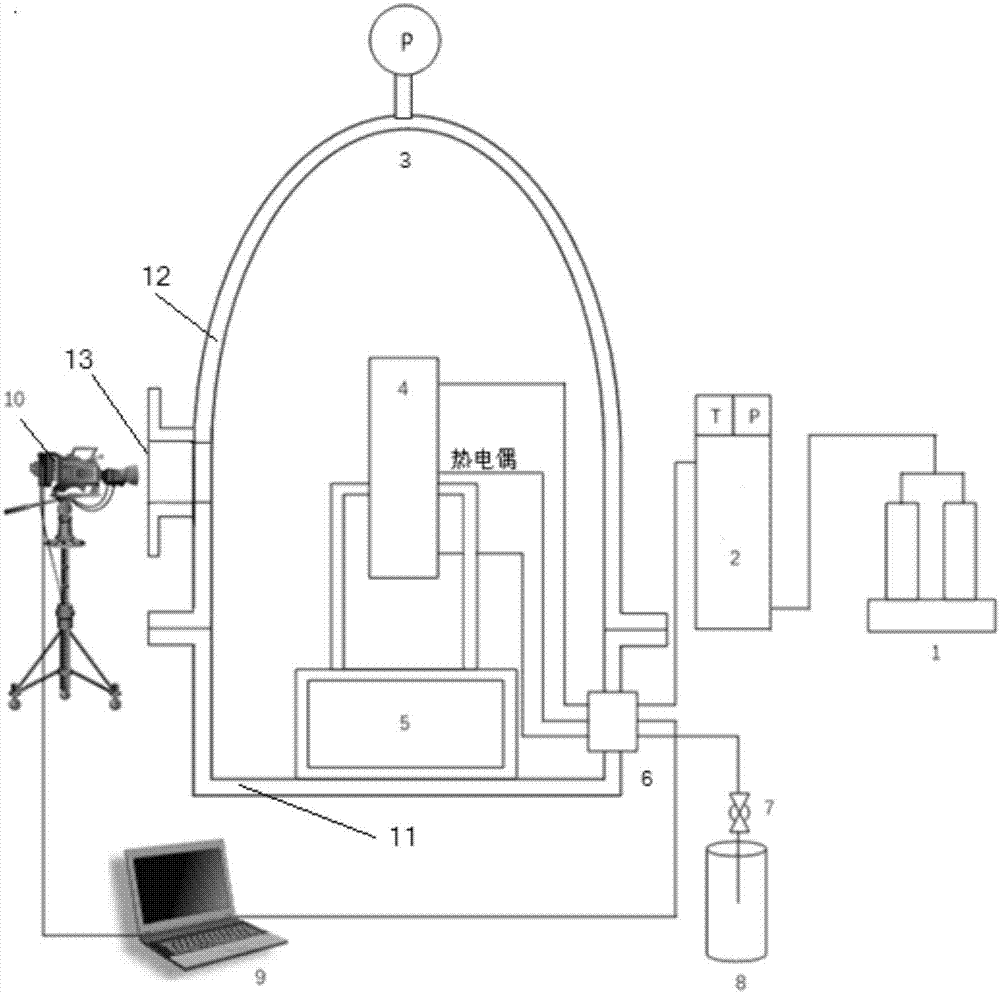

[0030] A physical simulation device for thermal recovery of heavy oil based on vacuum method and its working method, including:

[0031] Vacuum insulation cabin: vacuumize the insulation cabin;

[0032] Experimental model: set in the vacuum insulation cabin, used to inject steam to simulate the thermal recovery process of heavy oil; the experimental model includes: quartz sand, injection well and production well;

[0033] Steam generating part: arranged outside the vacuum insulation cabin, connected to the experimental model through pipelines;

[0034] Production fluid recovery pipeline: used to recover production fluid during heavy oil thermal recovery.

Embodiment 2

[0036] A physical simulation device for thermal recovery of heavy oil based on the vacuum method and its working method as described in Example 1, the difference is that the vacuum heat insulation cabin includes a bottom tank and a hatch cover that are connected to each other by buckling flanges.

Embodiment 3

[0038] A physical simulation device for thermal recovery of heavy oil based on vacuum method and its working method as described in Example 2, the difference is that the inner diameter of the vacuum insulation cabin is 1000-1500mm, and the height of the vacuum insulation cabin is 1200-2000mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com