Industrial waste gas treatment system

A technology of industrial waste gas and treatment system, which is applied in the fields of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of poor treatment effect, affecting the service life and treatment effect of high-voltage static electricity, and unable to meet the requirements of industrial waste gas treatment, etc. Achieve the effect of reducing the adhesion of oil droplets and ensuring the effect of oil fume separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

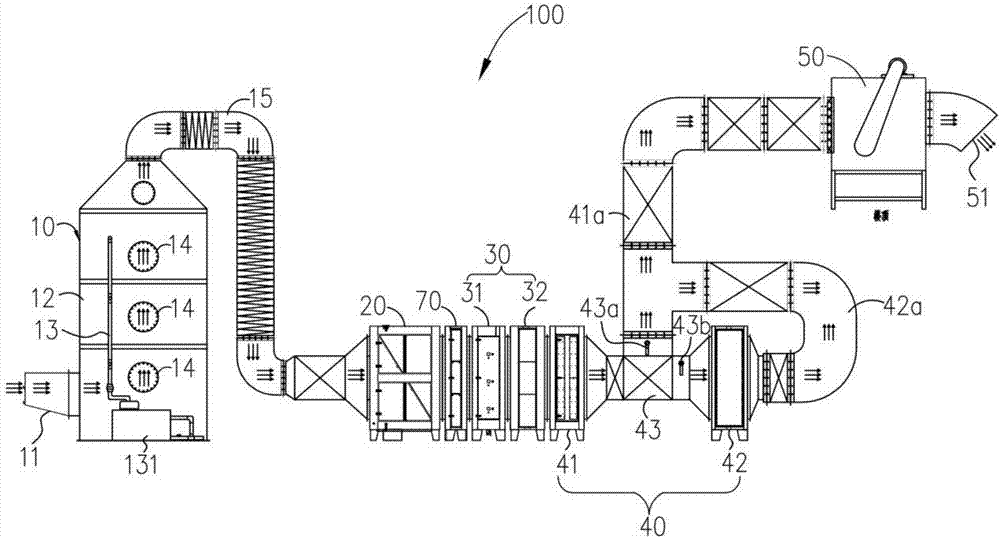

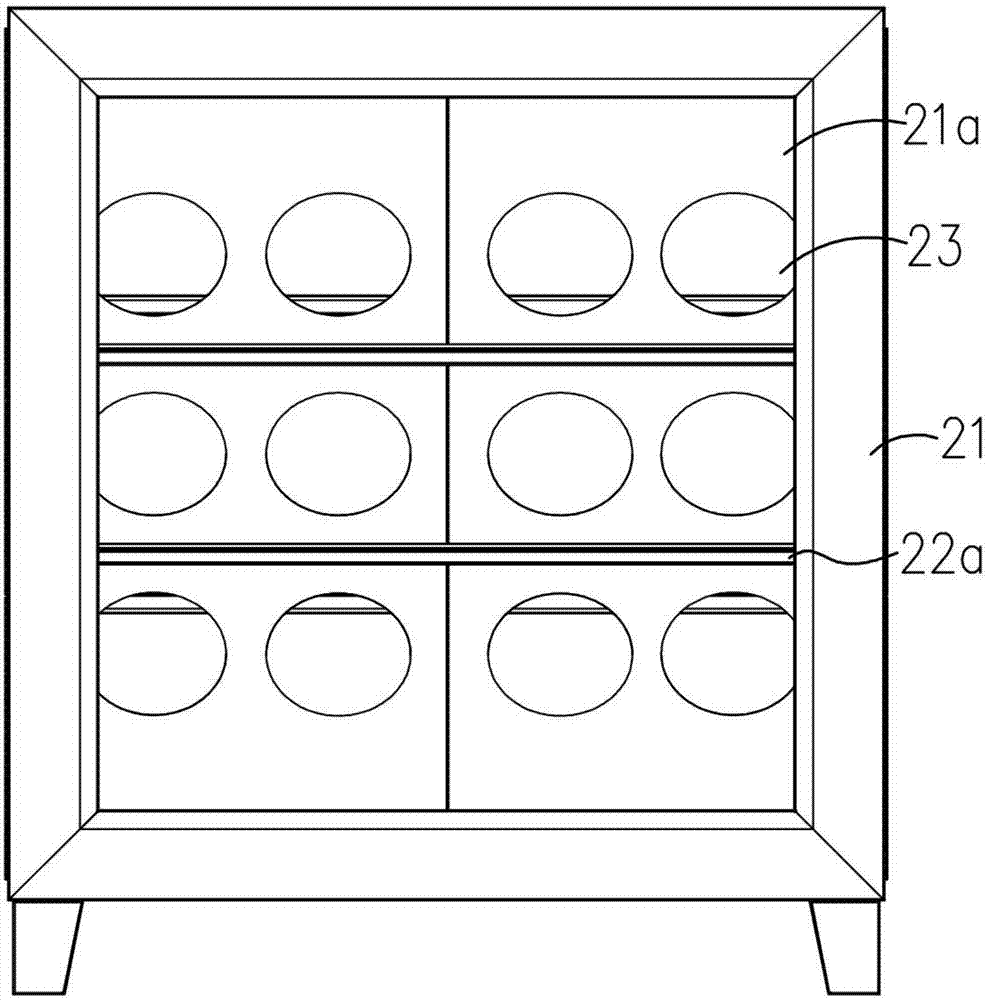

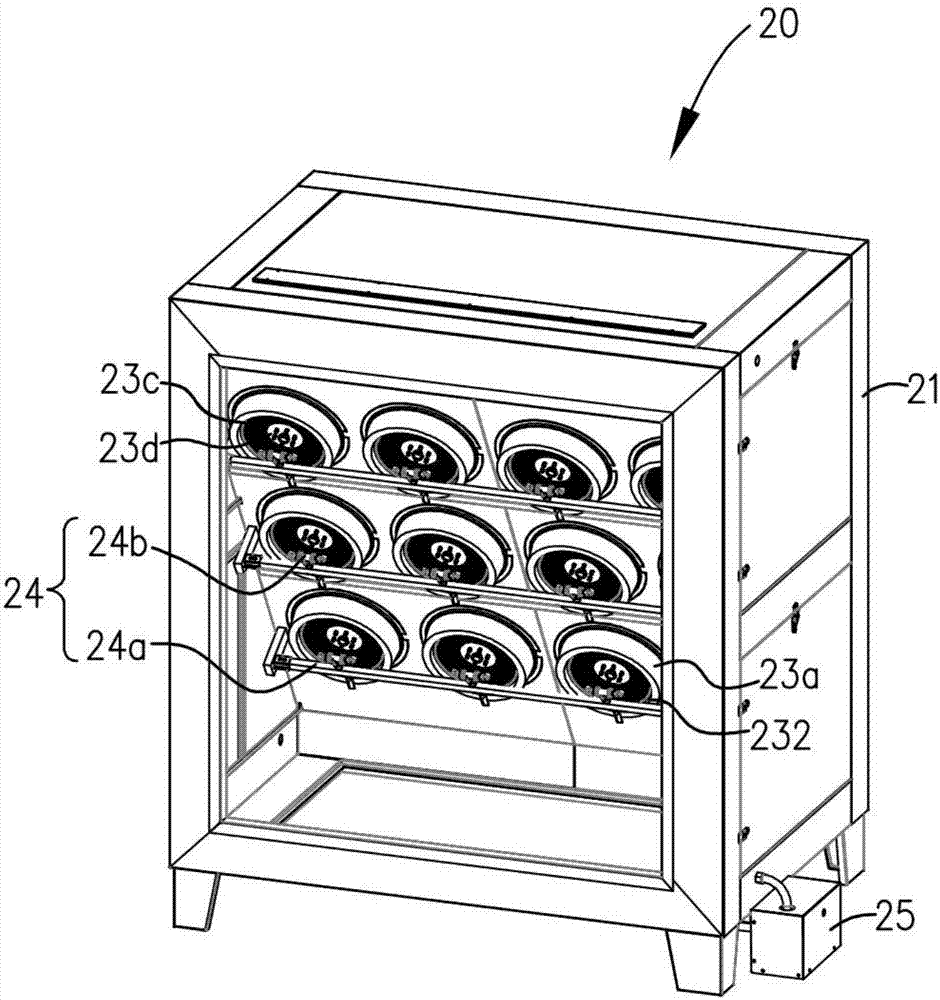

[0070] See figure 1, the first embodiment provides an industrial waste gas treatment system 100, including a spray device 10, an oil fume separation device 20, a smoke removal device 30, an odor removal device 40 and a fan 50, and the spray device 10 is provided with a waste gas inlet 11 and a liquid injection Assemblies (not shown), the exhaust gas inlet 11 communicates with the inside of the spraying device 10 , and the liquid injection assembly is arranged in the spraying device 10 . The smoke removal device 30, the deodorization device 40 and the fan 50 are sequentially connected and arranged outside the spray device 10. The fan 50 is provided with an air outlet 51. Industrial waste gas enters the spray device 10 from the waste gas inlet 11 and is sprayed by a liquid injection assembly to remove dust. After that, it is transported to the oil fume separation device 20 for oil fume separation, and then sequentially transported to the smoke removal device 30 and the deodoriza...

Embodiment 2

[0106] Please also refer to Figure 6 to Figure 7 , is a structural diagram of an industrial waste gas treatment system 200 provided in Embodiment 2 of the present invention. The difference between the industrial waste gas treatment system 200 of the second embodiment of the present invention and the industrial waste gas treatment system 100 of the first embodiment of the present invention is that:

[0107] A baffle plate 17 is arranged in the shower device 10, and the baffle board 17 divides the shower device 10 into a first part 10a and a second part 10b. The first part 10a is provided with a gas passage 101 leading to the second part 10b. The liquid The injection assembly is arranged in the first part 10a, and the oil fume separation device 20 is arranged in the second part 10b. That is to say, in this embodiment, the oil fume separation device 20 is disposed inside the spray device 10 . With this arrangement, the overall volume of the industrial waste gas treatment syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com