A stainless steel dinner plate processing technology

A processing technology, stainless steel technology, applied in the field of stainless steel dinner plate processing technology, can solve the problems of complicated production methods, incapable of intelligent control, and limited use range of stainless steel dinner plates, so as to achieve the effect of ensuring monitorability and simple and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

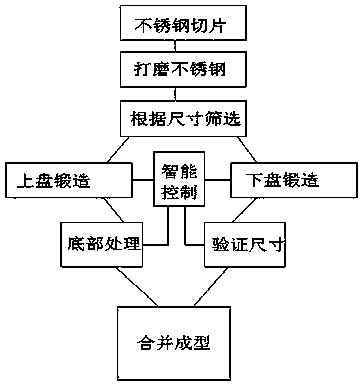

[0035] see Figure 1 to Figure 3 , the present invention provides a technical solution:

[0036]A stainless steel dinner plate processing technology, comprising the following steps,

[0037] Step 1, performing stainless steel slicing processing, and the stainless steel slicing is completed by a slicer;

[0038] Step 2, after the stainless steel slices are processed, the stainless steel grinding operation is performed, and the stainless steel grinding operation is carried out by a grinding machine;

[0039] Step 3: After polishing the stainless steel, use a screening machine to screen the stainless steel sheet according to its size;

[0040] Step 4, use different forging methods to process stainless steel sheets of different sizes, and perform upper plate forging and lower plate forging respectively;

[0041] Step 5: After forging the upper plate in step 4, use bottom treatment, the bottom treatment includes bottom forming and bottom grinding, and use verification dimension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com