Control system for controlling opening and closing of bottom doors of entire coal hopper cars with model 120 valve

A bottom door opening and closing and control system technology, which is applied to the direction of hopper cars, transport passenger cars, railway car body parts, etc., can solve the problem that the simultaneous unloading of the entire train, the simultaneous unloading of multiple connected vehicles, and the failure to connect multiple vehicles Signal transmission and other issues to ensure reliability and maintenance versatility, reduce development costs, and improve unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

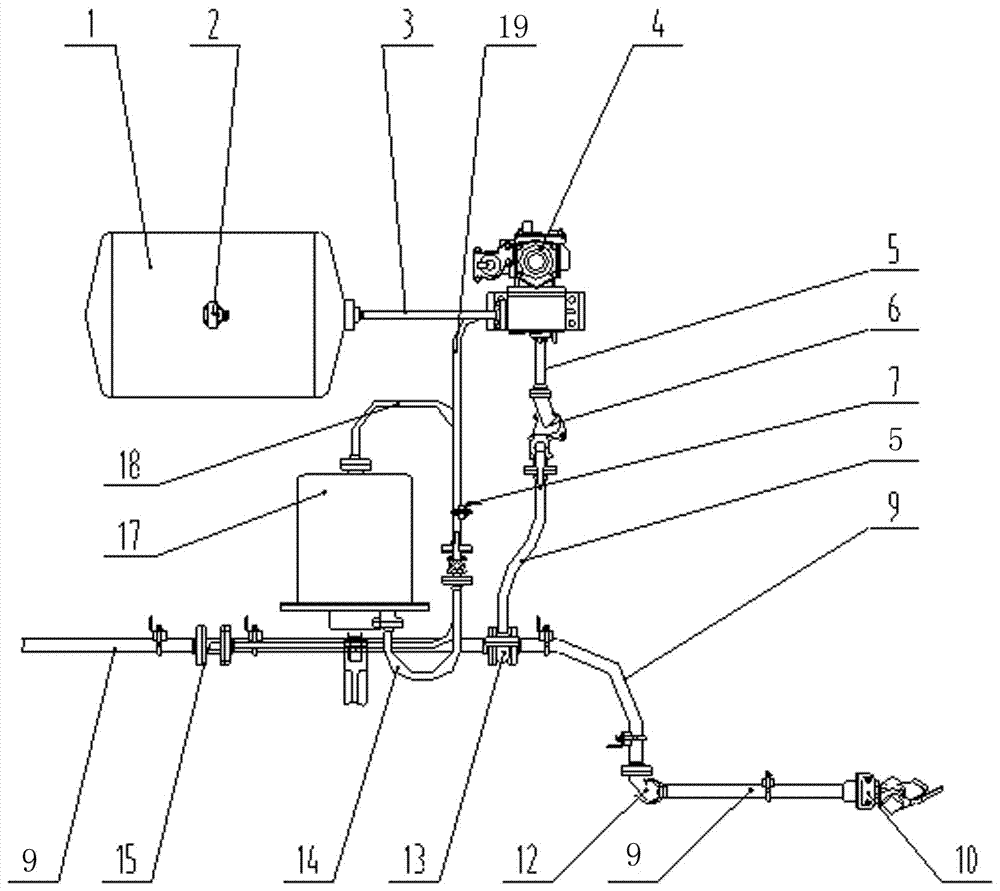

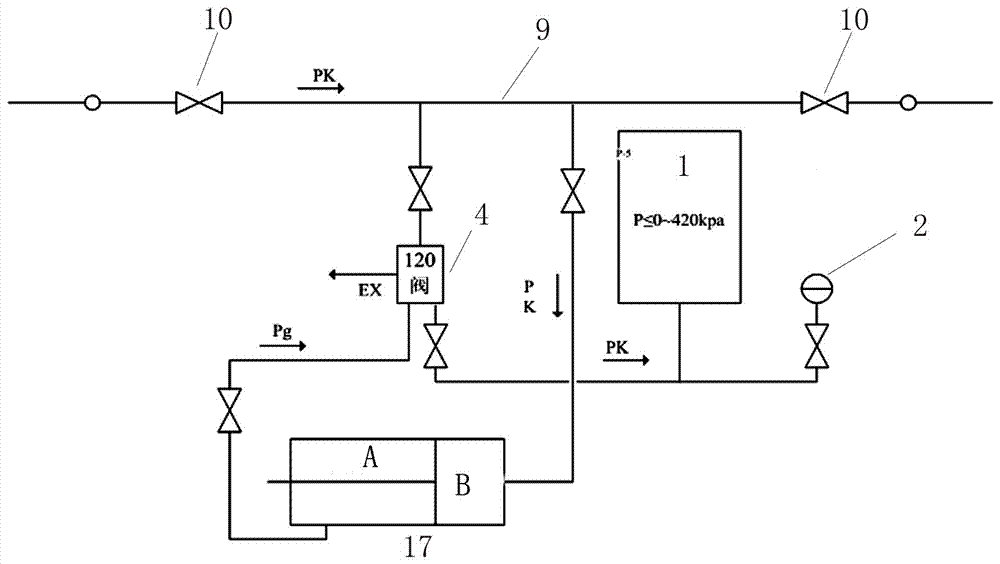

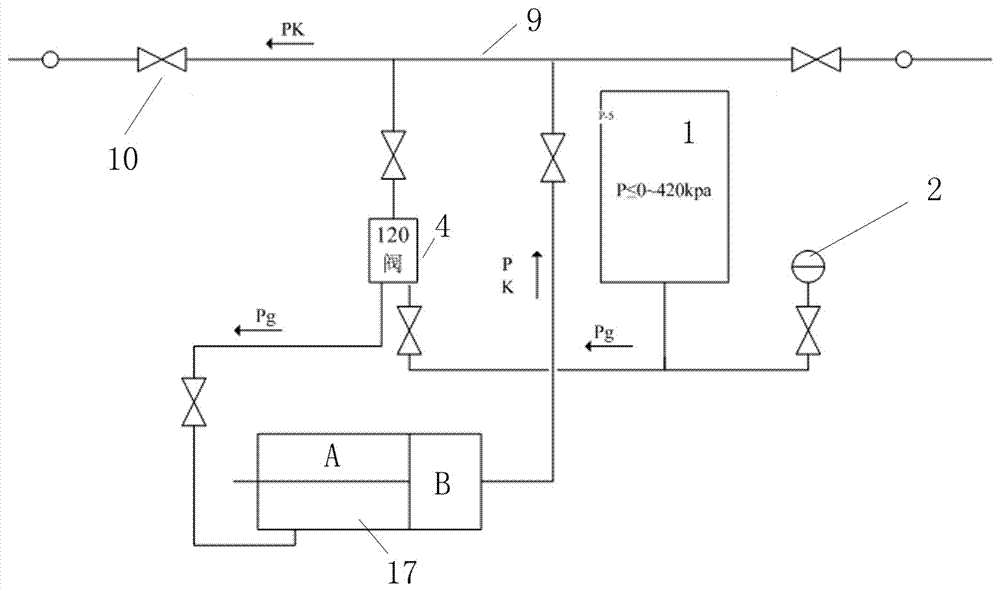

[0026] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

[0027] The railway freight car braking system is the key system of the vehicle, and the 120 control valve used in it is the core component of the railway vehicle braking system. In the braking system, the 120 valve controls the braking and relief of the braking device of the vehicle according to the change of the air pressure in the main train. It is the main control mechanism of the braking machine. The train supervisor is not only a pressure air delivery pipe that runs through the whole train, supplying pressure air to the brakes of each vehicle, but also a control pipe that transmits train braking, pressure maintaining or relief instructions.

[0028] The structure of the 120 control valve is as follows Figure 4 , 5 As shown in , 6, it consists of 4 parts: intermediate body, main valve, semi-automatic relief valve and emergency valve. There are air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com